Gradient damping composite material based on mass spring model and preparing method of gradient damping composite material

A damping composite material and spring model technology, applied in the field of damping composite materials, can solve the problems of low damping loss factor and narrow damping temperature range, and achieve the effect of simple method and high damping loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

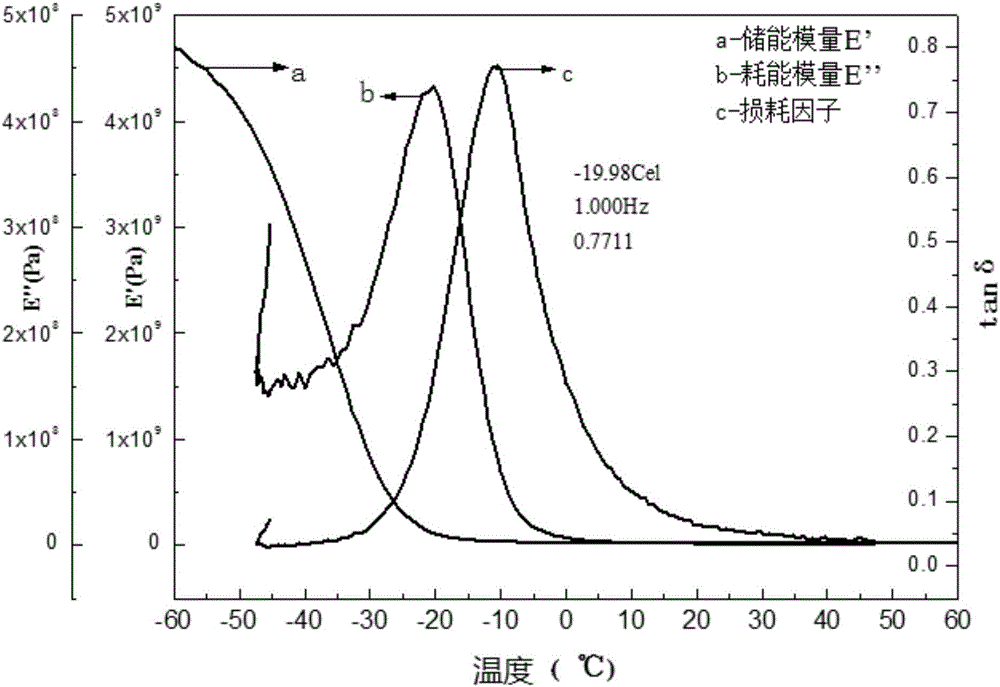

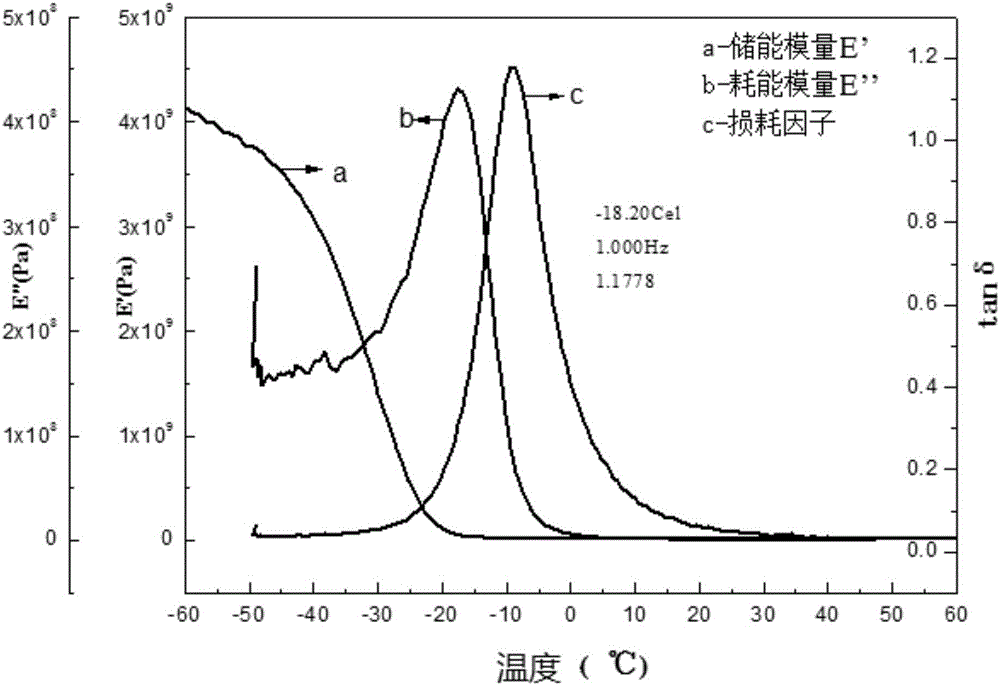

[0020] Specific embodiment 1: The gradient damping composite material based on the mass spring model of this embodiment is composed of multiple damping layers. The damping layer is composed of polyurethane elastomer-coated mass particles and basalt flake fibers; from bottom to top, the upper damping layer The degree of crosslinking of the polyurethane elastomer is greater than that of the polyurethane elastomer of the lower damping layer.

specific Embodiment approach 2

[0021] Embodiment 2: The method for preparing a gradient damping composite material based on a mass spring model described in Embodiment 1 is carried out in the following steps:

[0022] 1. Weigh the mass particles, polyurethane prepolymer, basalt flake fiber, chain extender and / or curing agent; wherein the mass ratio of the mass particles to the polyurethane prepolymer is (20-30): 100, the mass particles The mass ratio to basalt flake fiber is 1:(1~1.5), the mass of chain extender is M 1 22%-24% of the mass of the polyurethane prepolymer, the mass of the curing agent N 1 1% to 4% of the mass of the polyurethane prepolymer;

[0023] 2. Add the mass particles to the surface modifier, let it stand, filter out the settled mass particles, and take the upper liquid to obtain a dispersion of surface modified mass particles;

[0024] 3. Put the polyurethane prepolymer into a three-necked bottle, after vacuum degassing, add the surface-modified mass particle dispersion prepared in step two, ...

specific Embodiment approach 3

[0030] Specific embodiment three: This embodiment is different from specific embodiment two in that the polyurethane prepolymer described in step one is a reactive semi-finished product prepared from polyol and diisocyanate; wherein the total amount of -OH in the polyol is the same as that in the diisocyanate. -The molar ratio of the total amount of NCO is 1:2; the polyols are polyethylene adipate diol, polyethylene adipate, polycaprolactone polyol, and polycarbonate diol , Polybutylene adipate diol, polymethyl methacrylate, polyethyl methacrylate; the diisocyanate is 2,4-toluene diisocyanate, 2,4-toluene diisocyanate and A mixture of 2,6-toluene diisocyanate with a mass ratio of 80:20, 4,4-diphenylmethane diisocyanate, isophorone diisocyanate, or a mixture of two of them; the other and specific embodiment two the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com