Photo-thermal dual-responsive high-strength hydrogel and its preparation method and application

A dual-response, hydrogel technology, applied in the fields of smart windows, biomedicine, and light-controlled valves, can solve the problems of limited application and poor mechanical properties, and achieve the effect of changing hydrophilicity and hydrophobicity, good fatigue resistance, and fast reversible response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Synthesis of γ-PGA-GMA (Mn=1000000g / mol): first accurately weigh 4.01g of γ-PGA dissolved in 100mL of 5wt% NaHCO 3 In the aqueous solution, stir slowly until the γ-PGA is fully dissolved, then let stand to remove air bubbles; then add 0.1g 4-dimethylaminopyridine (DMAP), stir and dissolve fully, continue to slowly add 4.1mL glycidyl methacrylate ( GMA). Then the above solution was slowly stirred and reacted for 60 hours in the dark, and then the reacted solution was put into a dialysis bag with a molecular weight cut-off of 3500 and dialyzed in distilled water for three days, changing the water at least three times a day, and finally freeze-dried to obtain the target product γ-PGA- GMA. Its structure was characterized by nuclear magnetic technology, and its grafting rate was calculated to be 10%.

Embodiment 2

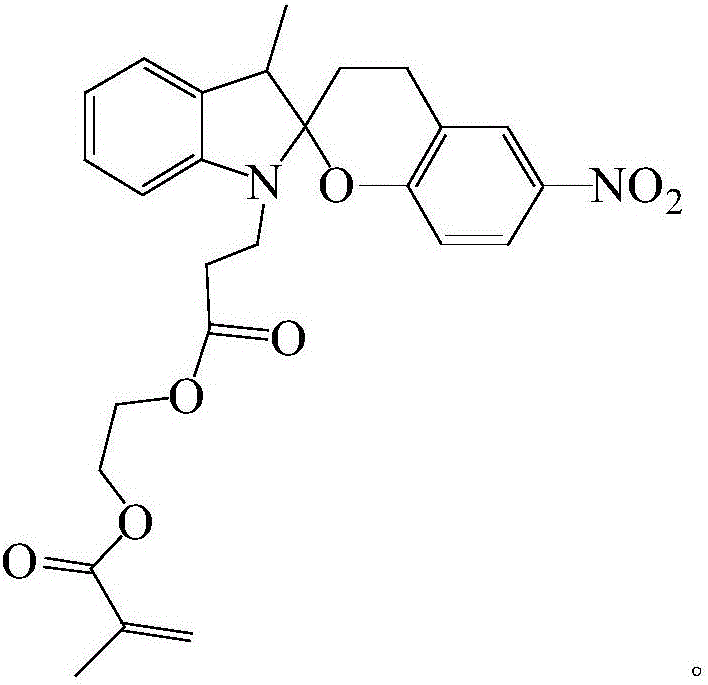

[0034] Synthesis of spiropyran monomer SPMA: All reaction vessels were wrapped with aluminum foil and protected from light.

[0035] (1) Accurately measure 10.1mL (0.06mol) of 2,3,3-trimethyl-3H-indole and 12.6g (0.06mol) of 3-iodopropionic acid and heat to 100°C under nitrogen for 3 hours; The remaining solid was dissolved in deionized water and washed with chloroform, then evaporated to remove water to obtain the iodide intermediate product-intermediate A, with a yield of 75%; its structural formula is as follows:

[0036]

[0037] (2) 14g (0.04mol) of intermediate A, 6.5g (0.04mol) of 5-nitrosalicylaldehyde and 3.8mL (0.04mol) of piperidine were dissolved in methyl ethyl ketone to obtain a red reaction solution, Refluxing for 3 hours; then standing overnight, a yellow powdery solid precipitated out. It was then filtered and washed repeatedly with methanol to obtain intermediate B with a yield of 78%. Its structural formula is as follows:

[0038]

[0039] (3) Accur...

Embodiment 3

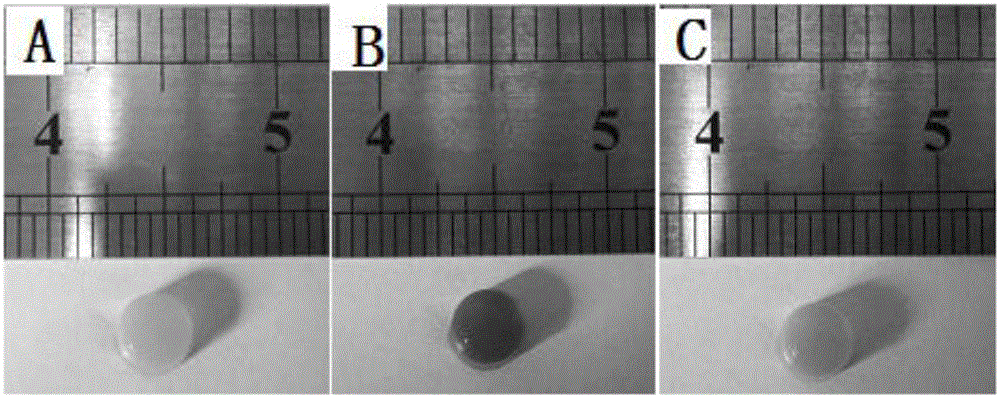

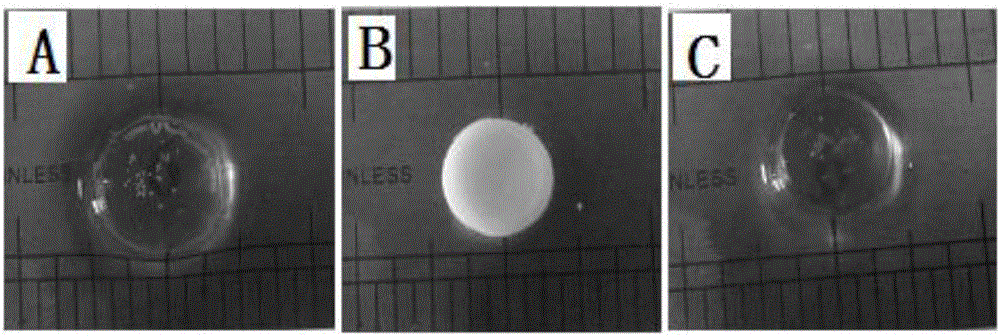

[0041] Prepare γ-PGA-GMA (Mn=1000000g / mol, grafting rate 10%) aqueous solutions with mass concentrations of 0.02g / mL and 0.03g / mL respectively, and add photoinitiator Irgacure 2959 to make the concentration 0.0005g / mL, centrifuged to remove air bubbles. Pipette the above solution and place it in a mold, and irradiate it under ultraviolet light with a wavelength of 365nm for 10 minutes to obtain the first network hydrogel γ-PGA hydrogel, named PGA2 and PGA3 respectively, and test its mechanical properties on a universal testing machine performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com