Light-weight scratch-resistant high-gloss material, preparation method of light-weight scratch-resistant high-gloss material, and application of light-weight scratch-resistant high-gloss material to preparation of automobile instrument panel

A scratch-resistant and lightweight technology, applied in the field of polypropylene composite materials, can solve the problems of reduced gloss, unsuitability, and strong odor of amide lubricants, and achieves the goal of reducing dial weight, protecting instrument panels, and improving air quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

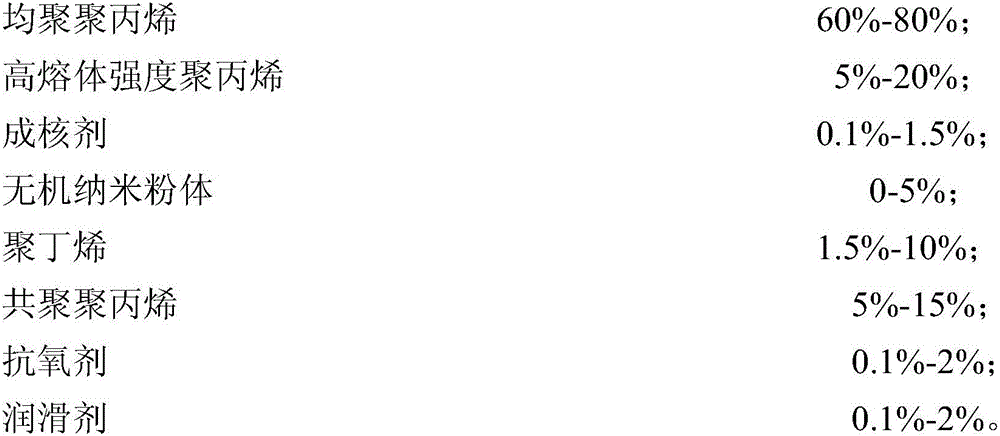

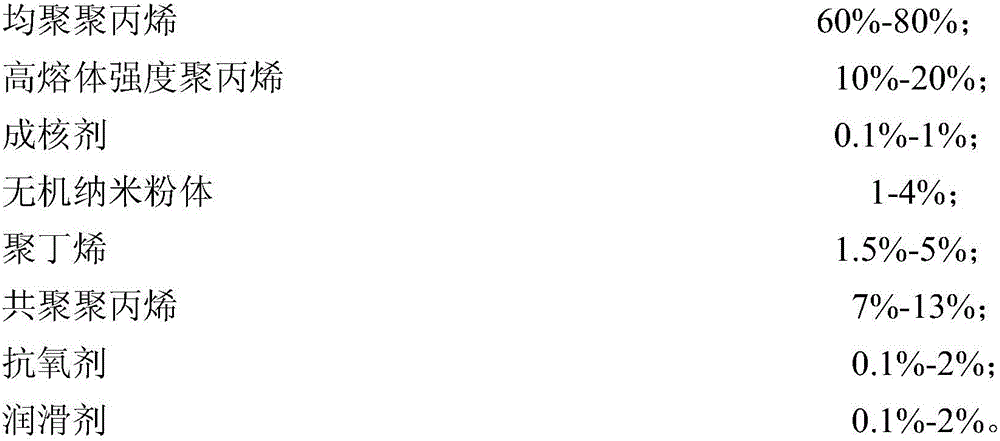

Method used

Image

Examples

Embodiment 1

[0039]After mixing polypropylene copolymer (Yanshan Petrochemical K9026, melt index 30g / l0min), nano talcum powder, antioxidants 1010 and 168, and calcium stearate at a weight ratio of 1:1, Prepare masterbatch by twin-screw extruder. 1496g homopolypropylene (Formosa Plastics 1080, melt index 10g / l0min), 240g high melt strength polypropylene (melt strength 35cN, melt index 3g / l0min), 4g 2,2'-methylene Base-bis(4,6-di-tert-butylphenol)sodium phosphate, 40g polybutene (LyondellBasell 0150M, 0.6g / l0min), 120g copolymerized polypropylene K9026, 100g functional additive masterbatch into high-speed mixing Mix in the machine for 10 minutes, the stirring temperature is 130-150°C, and the stirring speed is 300r / min; the mixture obtained above is fed into the twin-screw extruder through the main feeding port, and it is blended, extruded, cooled, pelletized, and dried , screening, and packaging, DEK is suitable for lightweight, low-odor, and scratch-resistant automotive dashboard materia...

Embodiment 2

[0041] Mix polypropylene copolymer (Yanshan Petrochemical K9026, melt index: 30g / l0min), nano-montmorillonite, antioxidants 1010 and 168 at a weight ratio of 1:1, and zinc stearate in a weight ratio of 4:3:2:1 Finally, masterbatches are prepared by a twin-screw extruder. 1330g homopolypropylene (Formosa Plastics 1124H, melt index is 15g / l0min), 300g high melt strength polypropylene (melt strength is 35cN, melt index is 3g / l0min), 10g bis(3,4-dimethyl Benzylbenzylidene) sorbitol, 60g polybutene (LyondellBasell 8220M, 46g / 10min), 100g copolymerized polypropylene K9026, 200g functional additive masterbatches were put into a high-speed mixer and mixed for 10min, and the stirring temperature was 130- 150°C, stirring speed 300r / min; the mixture obtained above is fed into the twin-screw extruder through the main feeding port, and after blending, extrusion, cooling, pelletizing, drying, screening, and packaging, it can be applied to Lightweight, low-odor, scratch-resistant automotive...

Embodiment 3

[0043] After mixing polypropylene copolymer (Yanshan Petrochemical K9026, melt index 30g / l0min), nano-calcium carbonate, antioxidants 1010 and 168 in a weight ratio of 1:1, and calcium stearate in a weight ratio of 4:3:2:1 Prepare masterbatch by twin-screw extruder. 1228g homopolypropylene (Shanghai Petrochemical Y2600T, melt index is 25g / l0min), 360g high melt strength polypropylene (melt strength is 35cN, melt index is 3g / l0min), 2g pimelic acid, 30g polybutene (LyondellBasell 8220M, 46g / 10min), 160g of copolymerized polypropylene K9026, 200g of functional additive masterbatches were put into a high-speed mixer and mixed for 10min, the stirring temperature was 130-150°C, and the stirring speed was 300r / min; The mixture is fed into the twin-screw extruder through the main feeding port, and after blending, extrusion, cooling, pelletizing, drying, screening, and packaging, it is suitable for lightweight, low-odor, and scratch-resistant automotive dashboard materials ; Among th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt strength | aaaaa | aaaaa |

| Melt strength | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com