Method for degrading malachite green by using bacterial cellulose membrane-immobilized phanerochaete chrysosporium

A technology of bacterial cellulose membrane and Phanerochaete protothecoides, which is applied in the directions of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve the inconvenience of post-treatment of wastewater, slow growth rate, and reduce the degradation of malachite green. efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

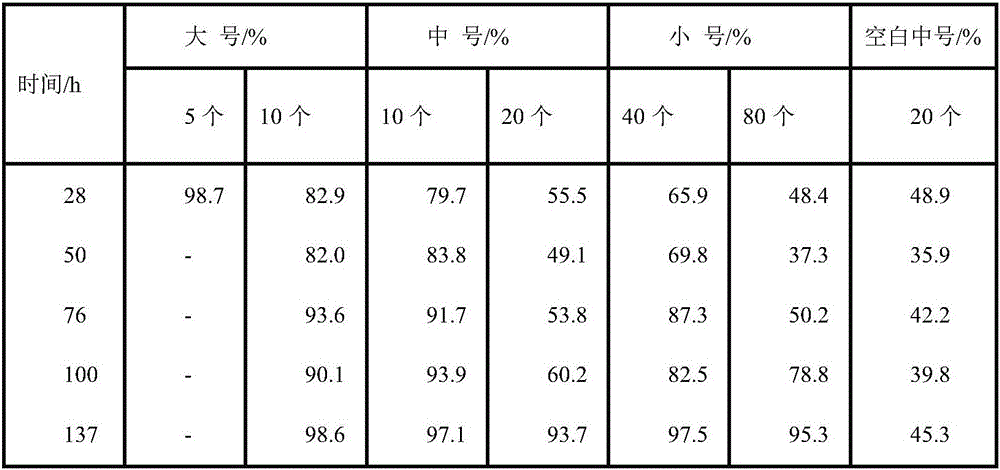

[0030] Preparation of bacterial cellulose membrane carrier: Acetobacter xylinum NUST4.2 is used as the strain, produced by static fermentation culture, purified and treated to obtain bacterial cellulose wet membrane. The bacterial cellulose membrane was cut into three types of small, medium and large cuboid pieces, the sizes of which were 0.5cm×0.5cm×0.3cm, 1.0cm×0.8cm×0.5cm, 1.5cm×1.2cm× 1.0cm, respectively, sterilized at 121°C for 30 minutes, and set aside.

[0031] Step 3, preparing the spore suspension of Phanerochaete chrysosporium;

[0032] Preparation of spore suspension: Connect Phanerochaete chrysosporium to a solid plate medium, culture at a constant temperature of 30°C for 7 days, then connect the grown spores of Phanerochaete chrysosporium to glass beads and 50mL, 0.85 % of sterilized physiological saline in a Erlenmeyer flask, shake and disperse to obtain a spore suspension of Phanerochaete chrysosporium, and store it in a refrigerator at 4°C for future use.

[...

Embodiment 1

[0046] Step 1 Preparation of solid plate medium: 200g fresh potato pieces, add water and boil for 30min, filter through 8 layers of gauze, take the filtrate, glucose 20g, potassium dihydrogen phosphate 1.5g, magnesium sulfate 0.75g, agar 20g, dilute to 1L, pH natural.

[0047] Step 2: Preparation of the bacterial cellulose membrane carrier: Acetobacter xylinum NUST4.2 is used as the strain, produced by static fermentation, purified and treated to obtain the bacterial cellulose wet membrane. Cut the obtained bacterial cellulose membrane into 5 large cuboid pieces (1.5cm×1.2cm×1.0cm), sterilize at 121°C for 30min, and set aside.

[0048] Step 3 Preparation of spore suspension: Connect Phanerochaete chrysosporium to its solid plate culture medium, culture at a constant temperature of 30°C for 7 days, then connect the spores of the grown fungus to glass beads and 50mL, 0.85% Sterilized physiological saline is shaken and dispersed to obtain a certain concentration of Phanerochaete...

Embodiment 2

[0053] Step 1 Preparation of solid plate medium: 200g fresh potato pieces, add water and boil for 30min, filter through 8 layers of gauze, take the filtrate, glucose 20g, potassium dihydrogen phosphate 1.5g, magnesium sulfate 0.75g, agar 20g, dilute to 1L, pH natural.

[0054] Step 2: Preparation of the bacterial cellulose membrane carrier: Acetobacter xylinum NUST4.2 is used as the strain, produced by static fermentation, purified and treated to obtain the bacterial cellulose wet membrane. Cut the obtained bacterial cellulose membrane into 10 large (1.5cm×1.2cm×1.0cm) cuboid pieces, sterilize at 121° C. for 30 minutes, and set aside.

[0055] Step 3 Preparation of spore suspension: Connect Phanerochaete chrysosporium to its solid plate culture medium, culture at a constant temperature of 30°C for 7 days, then connect the spores of the grown fungus to glass beads and 50mL, 0.85% Sterilized physiological saline is shaken and dispersed to obtain a certain concentration of Phane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com