Method for preparing cnts-porous nickel/nickel oxide catalyst for hydrogen evolution reaction on steel surface

A technology of steel surface and hydrogen evolution reaction, which is applied in the direction of electrode shape/type, coating, electrolytic components, etc., can solve the problems of high hydrogen evolution activation energy and low energy conversion efficiency, so as to improve catalytic activity, reduce energy consumption, and reduce hydrogen evolution The effect of the activation energy of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

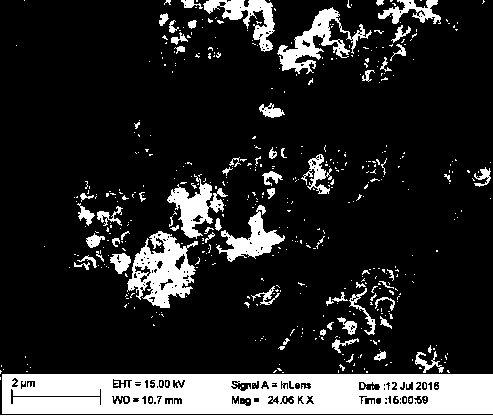

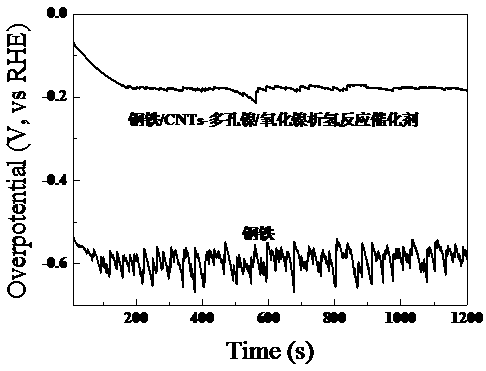

[0016] Specific embodiment one: the method for preparing CNTs-porous nickel / nickel oxide hydrogen evolution reaction catalyst on the steel surface of the present embodiment is carried out according to the following steps:

[0017] (1) Preparation of nickel-copper alloy-CNTs composite electroplating solution: a. Weigh 0.1–2.0 g of cetyltrimethylammonium bromide, add it to 800 mL of deionized water, stir at room temperature for 20 min, Add 0.2-1.0 g of carbon nanotubes; b. Stir at 25 °C for 0.5 h and then use an ultrasonic cell pulverizer for 1.5 h; c. Repeat step b 1-5 times; d. According to the concentration of ammonium citrate at 35- 65 g / L, the concentration of potassium sodium tartrate is 5~30 g / L, the concentration of nickel sulfate is 8~50 g / L, and the concentration of copper sulfate is 2~25 g / L. Ammonium citrate, potassium tartrate Sodium, nickel sulfate and copper sulfate are sequentially added to the solution treated in step c, and the pH is adjusted to be 7.5 to 8.5 t...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the concentration of nickel sulfate described in step (1) d is 12 ~ 40 g / L, and the concentration of described copper sulfate is 3 ~ 20 g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the electrodeposition time in step (4) is 20 min to 2 h. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com