Plug-in type gas blaster

A blaster and plug-in technology, which is applied in the blaster field, can solve the problems of low heat absorption efficiency of liquid carbon dioxide, seldom application of liquid oxygen explosive technology, and low thermal release efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

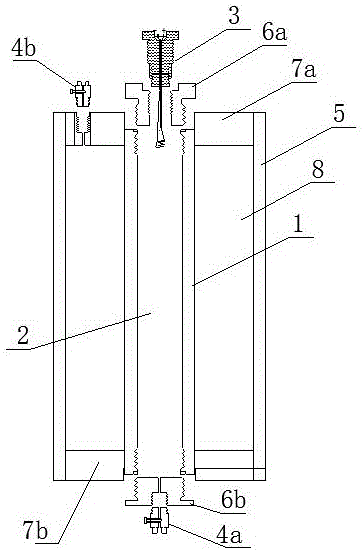

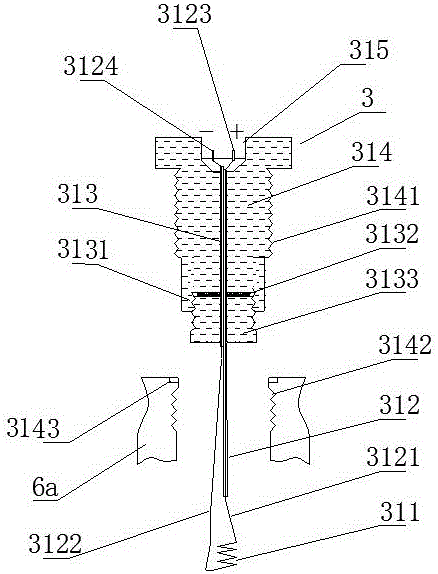

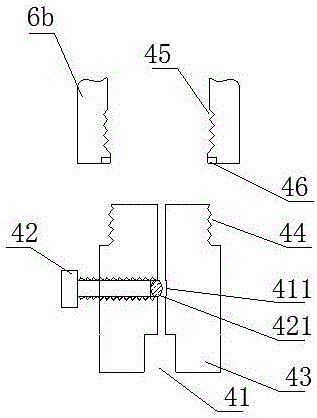

[0109] A plug-in gas blaster such as figure 1 As shown, it includes an inner tube 1, an inner tube filling cavity 2, an ignition mechanism 3, an inner tube inflation mechanism 4a and an outer tube 5, the inner tube 1 is an inner tube filling cavity 2, and the two ends of the inner tube 1 are respectively sealed and connected with The first sealing inner cover 6a and the second sealing inner cover 6b, the outer layer of the inner tube 1 is the outer tube 5, and the first sealing outer cover 7a and the second sealing outer cover 7b are sealingly connected between the inner tube 1 and the outer tube 5 , the first sealing cover 7a and the second sealing cover 7b are located at both ends of the outer tube 5,

[0110] The sealed cavity between the inner tube 1 and the outer tube 5 is the outer tube filling cavity 8, and the inner tube filling cavity 2 is filled with a reducing agent and an oxidizing agent, and the oxidizing agent is supercritical oxygen, high-pressure gas oxygen or ...

Embodiment 2

[0125] The difference with embodiment 1 is: as Figure 4 As shown, the inner tube 1 includes a first segmented body 11 and a second segmented body 12, the first segmented body 11 and the second segmented body 12 are connected through a threaded structure, and are matched with a threaded sealing ring 13 for Sealing; the first sealing inner cover 6a and the second sealing inner cover 6b are respectively connected to both sides of the first segment body 11 and the second segment body 11; this structure is convenient for charging.

Embodiment 3

[0127] The difference with embodiment 1 is: as Figure 5 As shown, the inner tube 1 is a composite layer tube containing fiber material, and the inner tube 1 includes: a matrix layer 101, a fiber layer 102, and a hardened layer 103 from the inside to the outside; one end of the inner tube 1 is sealed. Wrapped with a first metal joint 111, the other end of the inner tube 1 is sealed and wrapped with a second metal joint 112, the first metal joint 111 and the second metal joint 112 are respectively connected to the inner tube inflation mechanism 4a and the ignition mechanism 3; the first metal The bottoms of the joint 111 and the second metal joint 112 protrude outwards to avoid falling off with the inner tube 1 .

[0128] As a further description of the above embodiment, the base layer 101 is made of polyethylene (PE); the fiber layer 102 is made of glass fiber; the hardened layer 103 is made of epoxy resin.

[0129] As a further description of the above embodiment, the implem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com