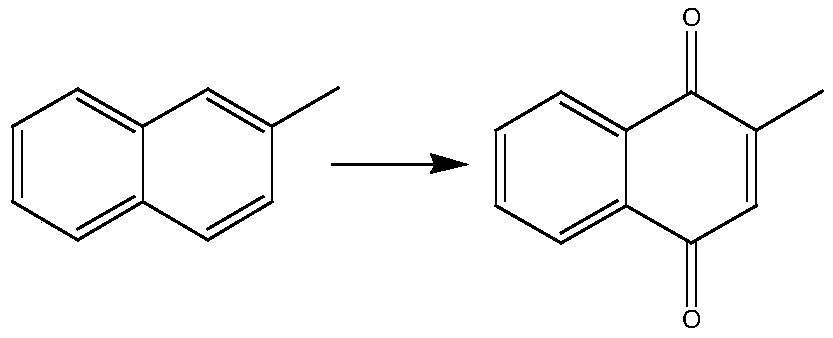

A kind of rhenium catalyst and its catalytic method for synthesizing 2-methyl-1,4-naphthoquinone

A technology of catalyst and methyl, which is applied in the field of rhenium catalyst and its catalytic synthesis of 2-methyl-1,4-naphthoquinone, which can solve the problems of low reaction efficiency, large amount of catalyst, environmental pollution, etc., and achieve high activity and preparation The method is simple and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

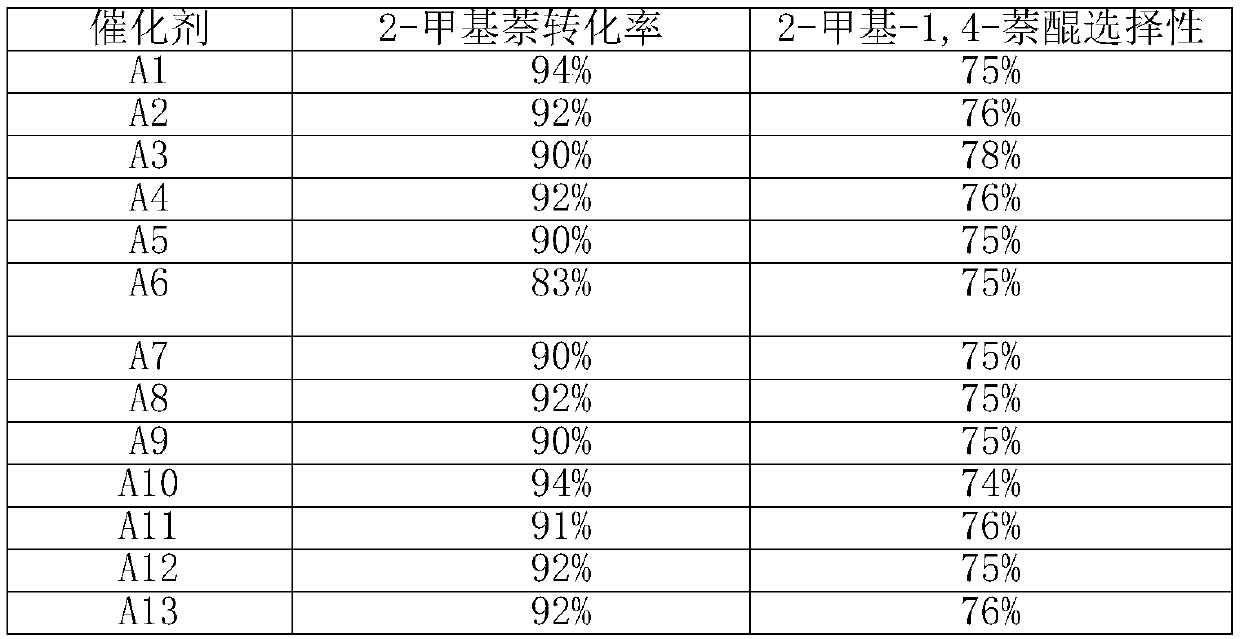

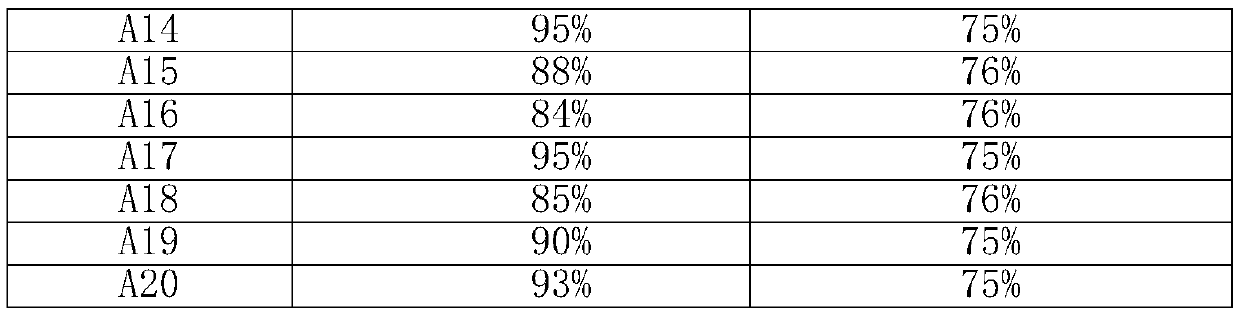

Examples

Embodiment example 1

[0018] Measure the perrhenic acid solution containing 0.0100g metal rhenium in a round bottom flask, dilute it with 20ml methanol as a solvent, then add 1.0000g activated carbon to the solution, and stir at room temperature for 4h. Move the round bottom flask to an oil bath at 50°C, and add 0.1576mg of 1-methyl-3-cyanomethylimidazolium chloride into the round bottom flask, and continue stirring at this temperature for 12h. After the stirring, the round-bottomed flask was placed on a rotary evaporator to dry the solvent, and then dried overnight at 40°C in a vacuum oven, and the obtained precatalyst was calcined in a tube furnace under a nitrogen atmosphere until the temperature was 600°C. The heating rate was 5°C / min, and the temperature was maintained for 2h. Catalyst A1 (rhenium loading 1%) was obtained after natural cooling to room temperature.

Embodiment example 2

[0020] Measure the perrhenic acid solution containing 0.0100g metal rhenium in a round bottom flask, dilute it with 20ml methanol as a solvent, then add 1.0000g activated carbon to the solution, and stir at room temperature for 4h. Move the round bottom flask to an oil bath at 50°C, and add 0.1576mg of 1-methyl-3-cyanomethylimidazolium chloride into the round bottom flask, and continue stirring at this temperature for 12h. After the stirring, the round-bottomed flask was placed on a rotary evaporator to dry the solvent, then dried overnight at 40°C in a vacuum oven, and the obtained precatalyst was calcined in a tube furnace under a nitrogen atmosphere until the temperature was 700°C. The heating rate was 5°C / min, and the temperature was maintained for 2h. Catalyst A2 (rhenium loading 1%) was obtained after natural cooling to room temperature.

Embodiment example 3

[0022] Measure the perrhenic acid solution containing 0.0100g metal rhenium in a round bottom flask, dilute it with 20ml methanol as a solvent, then add 1.0000g activated carbon to the solution, and stir at room temperature for 4h. Move the round bottom flask to an oil bath at 50°C, and add 0.1576mg of 1-methyl-3-cyanomethylimidazolium chloride into the round bottom flask, and continue stirring at this temperature for 12h. After the stirring, the round-bottomed flask was placed on a rotary evaporator to dry the solvent, and then dried overnight at 40°C in a vacuum oven, and the obtained precatalyst was calcined in a tube furnace under a nitrogen atmosphere until the temperature was 800°C. The heating rate was 5°C / min, and the temperature was maintained for 2h. After naturally cooling down to room temperature, catalyst A3 (rhenium loading was 1%) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com