Control method for electric spark pulse power supply device

A technology of pulse power supply and control method, applied in circuits, manufacturing tools, electric processing equipment, etc., can solve problems such as affecting processing efficiency and processing quality, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

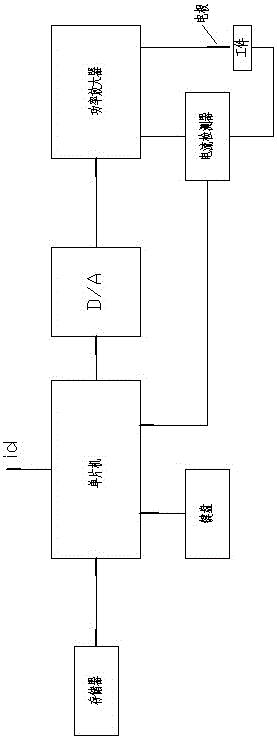

[0019] A control method for an electric spark pulse power supply device, the electric spark pulse power supply device includes a pulse signal generator composed of a single-chip microcomputer and a D / A converter, a power amplifier for power amplifying the pulse signal, and a power amplifier for detecting the power of the power amplifier. A current detector for output current, a memory for storing pulse signal information and output current information, and a keyboard for inputting data; its control method is realized by running the internal program of the single-chip microcomputer.

[0020] After starting up, the workpiece on the EDM machine moves to the electrode or the electrode moves to the workpiece at a certain speed;

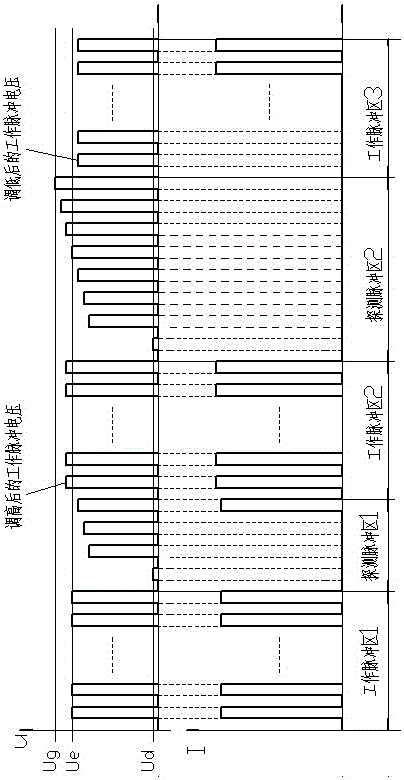

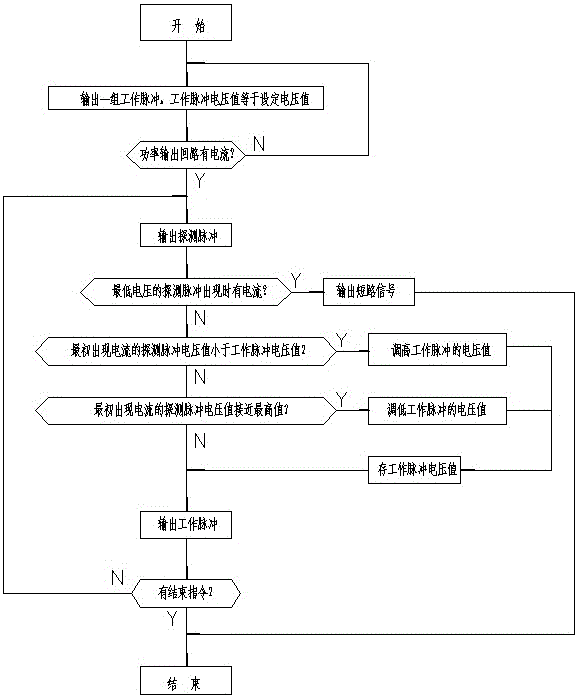

[0021] Run the internal program of the single chip microcomputer (the program flow chart is as follows image 3 Shown), the prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com