Method for producing iron oxide black with fluorine-titanium mother liquor

A technology of iron oxide black and mother liquor, which is applied in the field of inorganic pigments, can solve the problems of wasting iron resources and environmental pollution, and achieve the effects of reducing energy consumption and production costs, increasing economic benefits, and good use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

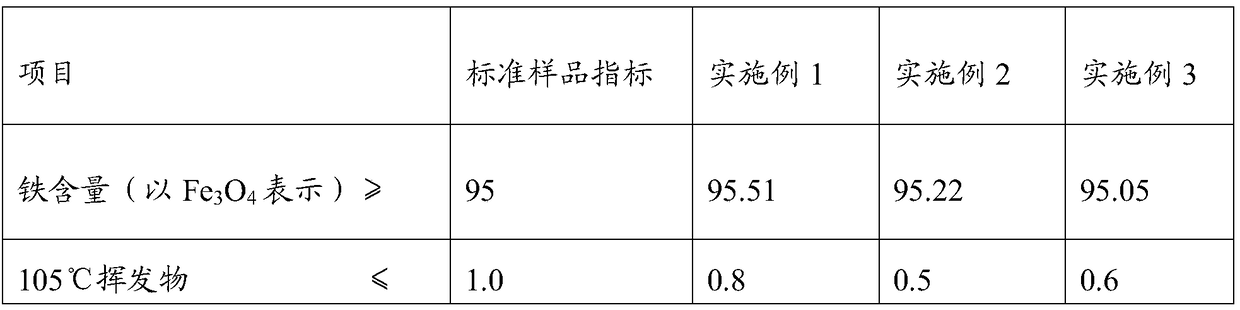

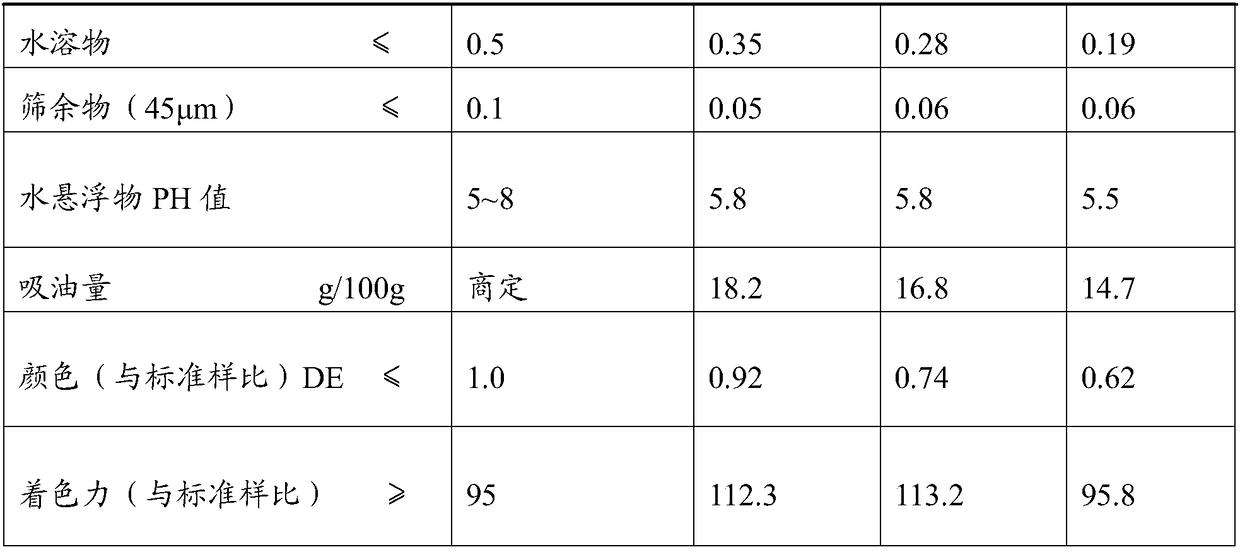

Embodiment 1

[0046] Take about 4000ml of fluorine-titanium mother liquor in a 5L beaker, add excess small iron pieces, heat to 50-60°C, react until the solution pH=4.0, filter with suction, and filter out the precipitated Ti(OH) 3 , and analyze ferrous chloride concentration (expressed as Fe) in the filtrate to be 86g / L; Get ferrous chloride solution 2090ml in 5L beaker, add water 910ml to adjust ferrous chloride concentration, stir, add concentration 15% ammoniacal liquor Neutralize and adjust to PH=10; heat to 90°C, slowly add 380ml of sodium chlorate solution with a concentration of 10%, keep the pH value in the range of 8.5-9.0 during the oxidation process, and the temperature is 90-95°C. After the sodium chlorate is added, the reaction is completed, the slurry is suction filtered, the filter cake is washed with water until the conductivity of the washing water is less than 1000 μs / cm, and then dried in an oven to obtain iron oxide black.

Embodiment 2

[0048] Take about 4000ml of fluoride-titanium mother liquor in a 5L beaker, add excess small iron pieces, heat to 60-70°C, react until the solution pH=4.5, filter with suction, and filter out the precipitated Ti(OH) 3, and analyze the ferrous chloride concentration (expressed as Fe) in the filtrate to be 89.2g / L; Get ferrous chloride solution 2180ml in the 5L beaker, add water 820ml to adjust the concentration of ferrous chloride, stir well, add concentration 15 Neutralize with % ammonia water and adjust to PH=9; heat to 93°C, slowly add 410ml of sodium chlorate solution with a concentration of 10%, keep the pH value in the range of 7.5 to 8.5 during the oxidation process, and the temperature is 93 to 95°C. After the sodium chlorate is added, the reaction is completed, the slurry is suction filtered, the filter cake is washed with water until the conductivity of the washing water is less than 1000 μs / cm, and then dried in an oven to obtain iron oxide black.

Embodiment 3

[0050] Take about 4000ml of fluorine-titanium mother liquor in a 5L beaker, add excess small iron pieces, heat to 70-80°C, react until the solution pH=4.5, filter with suction, and filter out the precipitated Ti(OH) 3 , and analyze ferrous chloride concentration (expressed as Fe) in the filtrate to be 88.5g / L; Get ferrous chloride solution 1865ml in 5L beaker, add water 1135ml to adjust filtrate concentration, stir, add concentration 15% ammoniacal liquor to neutralize , adjusted to PH=8.5; heated to 95°C, slowly adding 350ml of sodium chlorate solution with a concentration of 10%, keeping the pH value in the range of 7.0 to 8.0 during the oxidation process, and the temperature at 95 to 100°C. After the sodium chlorate is added, the reaction is completed, the slurry is suction filtered, the filter cake is washed with water until the conductivity of the washing water is less than 1000 μs / cm, and then dried in an oven to obtain iron oxide black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tinctorial strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com