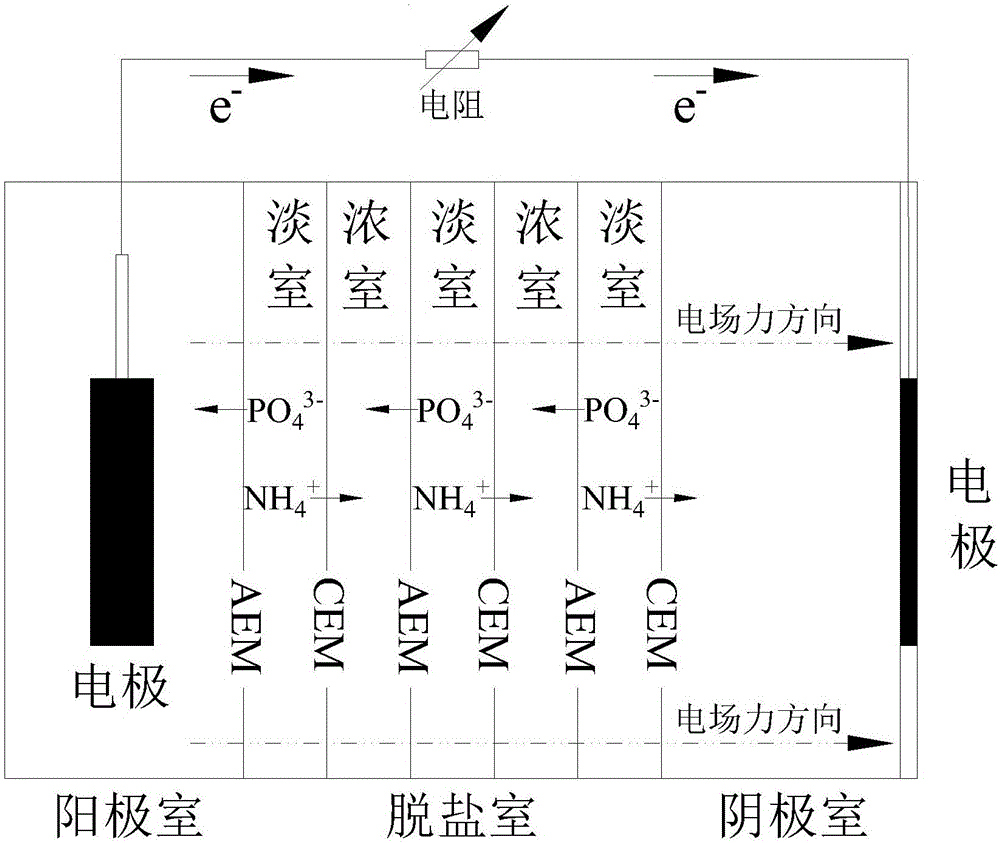

Denitrification method of ammonia-nitrogen wastewater and microbial desalination tank

A technology for ammonia nitrogen wastewater and microorganisms, which is applied in the fields of water pollutants, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of adding a large number of chemical agents, and achieve the effect of efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Take 1L of fertilizer wastewater with an ammonia nitrogen concentration of 289mg / L as the experimental sample, and enter the desalination chamber of the microbial desalination tank; add crushed human feces and water to the anode chamber of the microbial desalination tank according to the volume ratio of 1:1 as fuel; 0.066mol / L of KH 2 PO 4 and K of 0.035mol / L 2 HPO 4 ·3H 2 O was added to the cathode compartment of the microbial desalination cell as a buffer. When the hydraulic retention time is 6h, the concentration of ammonia nitrogen in the effluent water of the final desalination chamber is 20.2 mg / L, corresponding to a recovery rate of 93%, and the daily production capacity of the microbial desalination tank is about 3×10 -6 Spend.

Embodiment 2

[0059] Take 1L of aquaculture wastewater with an ammonia nitrogen concentration of 582mg / L as the experimental sample, and enter the desalination chamber of the microbial desalination tank; add the crushed human feces and water to the anode chamber of the microbial desalination tank according to the volume ratio of 0.9:1 as fuel; 0.036mol / L of KH 2 PO 4 and K of 0.025mol / L 2 HPO 4 ·3H 2 O was added to the cathode compartment of the microbial desalination cell as a buffer. When the hydraulic retention time is 6 hours, the concentration of ammonia nitrogen in the effluent of the final desalination chamber is 58.2mg / L, the corresponding recovery rate is 90%, and the daily production capacity of the microbial desalination pond is about 4×10 -6 Spend.

Embodiment 3

[0061] Take 1L of human urine with an ammonia nitrogen concentration of 375mg / L as the experimental sample, and enter the desalination chamber of the microbial desalination pool; add the crushed human feces and water to the anode chamber of the microbial desalination pool according to the volume ratio of 1.1:1 as fuel ; The KH of 0.05mol / L 2 PO 4 and K of 0.05mol / L 2 HPO 4 ·3H 2 O was added to the cathode compartment of the microbial desalination chamber as a buffer. When the hydraulic retention time is 6h, the concentration of ammonia nitrogen in the effluent of the final desalination chamber is 39 mg / L, the corresponding recovery rate is 92%, and the daily production capacity of the microbial desalination tank is about 4×10 -6 Spend.

[0062] It can be known from the above examples that the present invention provides a method for denitrification of ammonia nitrogen wastewater and a microbial desalination tank. The microbial desalination pool provided by the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com