Method for improving dewatering performance of excess sludge

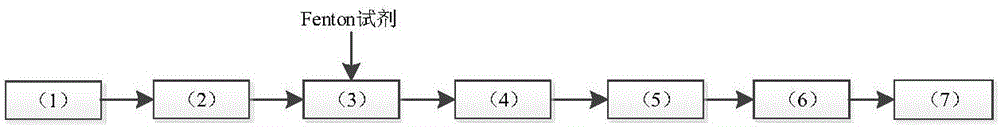

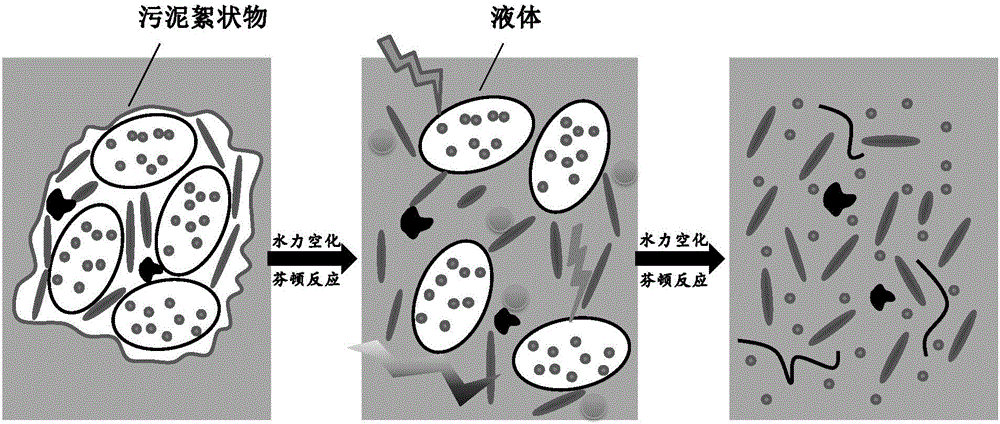

A technology of dewatering performance and excess sludge, applied in water/sludge/sewage treatment, sludge treatment, oxidation treatment of sludge, etc., can solve the problem of reduced sludge particle size, high cost, and increased sludge dewatering time, etc. problem, to achieve the effect of weakening the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

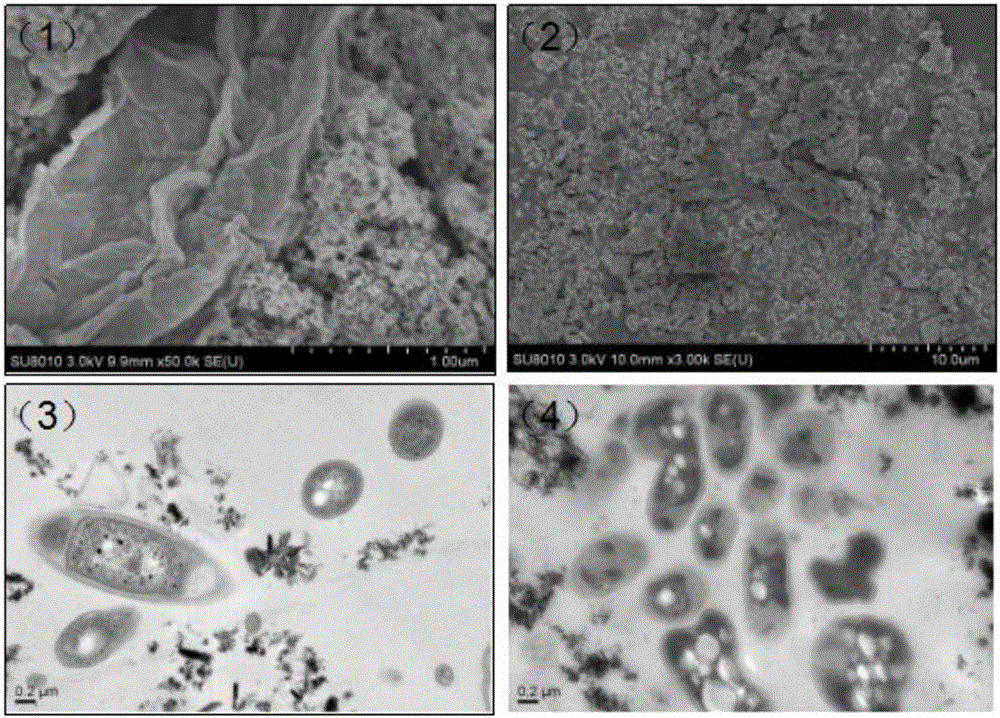

Method used

Image

Examples

Embodiment 1

[0039] Take the biochemical sludge with a moisture content of 98.2% and pour it into the water tank, adjust the pH=3.0, add the conditioner Fe 2+ , the addition amount is 0.05w% of the absolute dry weight of the sludge, and then add the conditioner H 2 o 2, the addition amount is 0.05w% of the absolute dry weight of the sludge, start the water conservancy cavitation device, and circulate for 10 minutes. The treated sludge is put into the high-pressure membrane filter press for dehydration (the parameters of this process and the performance parameters of the high-pressure membrane filter press also need to be explained), after dehydration, the moisture content of the sludge reaches 53.1%, and the solid content decreases by 18.4%. .

Embodiment 2

[0041] Take the biochemical sludge with a moisture content of 98.5% and pour it into the water tank, adjust the pH=3.0, add the conditioner Fe 2+ , the added amount is 0.08w% of the absolute dry weight of the sludge, and the conditioner H is added 2 o 2 , the addition amount is 0.08w% of the absolute dry weight of the sludge, start the water conservancy cavitation device, and circulate for 10 minutes. The treated sludge is put into a high-pressure diaphragm filter press for dehydration. After dehydration, the moisture content of the sludge reaches 52.2%, and the solid content decreases by 19.8%.

Embodiment 3

[0043] Take the biochemical sludge with a water content of 97.9% and pour it into the water tank, adjust the pH=3.0, add the conditioner Fe 2+ , the addition amount is 0.1w% of the absolute dry weight of the sludge, and then add the conditioner H 2 o 2 , the addition amount is 0.1w% of the absolute dry amount of sludge, start the water conservancy cavitation device, and circulate for 10 minutes. The treated sludge is put into a high-pressure diaphragm filter press for dehydration. After dehydration, the moisture content of the sludge reaches 50.8%, and the solid content decreases by 20.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com