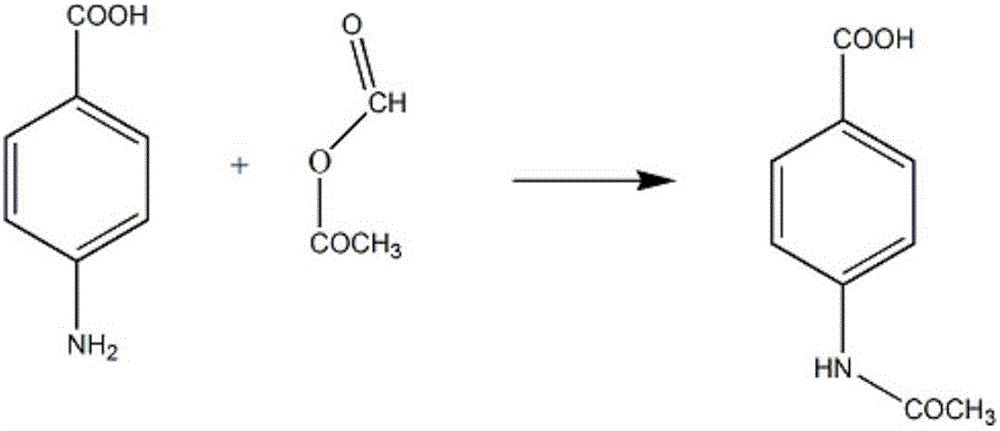

Method for synthesizing p-acetamidobenzoic acid as organic synthesis intermediate

A technology of acetaminophen and organic synthesis, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of complex process and low final yield, reduce intermediate links, shorten reaction time, The effect of increasing the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0011] Dissolve 5mol of p-aminobenzoic acid in 1.5L of 80% formic acid solution with a mass fraction of 80%, control the stirring speed at 130rpm, add 6mol of formic acetic anhydride, increase the solution temperature to 50°C, continue stirring for 70min, and distill under reduced pressure at 50kPa for 50min. Add 2L mass fraction of 15% potassium chloride solution to the solution, reduce the temperature of the solution to 10°C, precipitate crystals, filter, wash with a mass fraction of 10% sodium bromide solution, and recrystallize in a mass fraction of 90% ether solution. The solid sodium hydroxide dehydrating agent dehydrates to finally obtain 814.45 g of p-acetaminobenzoic acid, with a yield of 91%.

example 2

[0013] Dissolve 5mol of p-aminobenzoic acid in 1.6L of 82% formic acid solution with a mass fraction of 82%, control the stirring speed at 140rpm, add 6.2mol of formic acetic anhydride, raise the solution temperature to 52°C, continue stirring for 80min, and distill under reduced pressure at 55kPa for 60min. Add 2.5L mass fraction of 17% potassium chloride solution to the remaining solution, reduce the temperature of the solution to 12°C, precipitate crystals, filter, wash with a mass fraction of 12% sodium bromide solution, and reapply in a mass fraction of 92% ether solution. Crystallization, dehydration with anhydrous calcium sulfate dehydrating agent, and finally 832.35 g of the product p-acetaminobenzoic acid was obtained, with a yield of 93%.

example 3

[0015] Dissolve 5 mol of p-aminobenzoic acid in 1.8 L of formic acid solution with a mass fraction of 85%, control the stirring speed at 150 rpm, add 6.5 mol of formic acetic anhydride, increase the temperature of the solution to 55 ° C, continue stirring for 90 min, and distill under reduced pressure at 60 kPa for 70 min. Add 3L of 20% potassium chloride solution to the remaining solution, reduce the temperature of the solution to 15°C, precipitate crystals, filter, wash with 15% sodium bromide solution, and recrystallize in 95% ether solution , solid sodium hydroxide dehydrating agent dehydration, the final product p-acetaminobenzoic acid 859.20g, yield 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com