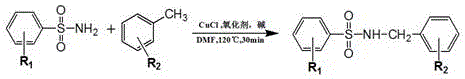

Synthesis process of sulfonamide compounds in microwave system

A technology for sulfonamides and synthesis processes, which is applied in the formation/introduction of sulfonyl/sulfinyl groups, the preparation of sulfonic acid amides, and organic chemistry, etc., and can solve problems such as limitations in the use of synthetic schemes, difficulty in obtaining raw materials, and severe reaction conditions. , to achieve the effect of high productivity, environmental friendliness and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: N-benzylbenzenesulfonamide: 1 mmol of benzenesulfonamide was added to the reaction vessel, followed by adding 2 mmol of ferric chloride, 0.1 mmol of cuprous chloride, 0.01 mmol of potassium carbonate, 4 mL of toluene, and dimethyl Dimethyl formamide (DMF) 3ml. Placed in a microwave reactor and heated to 120 °C under 150 W power for continuous reaction for 30 min. After the reaction was completed, it was cooled to room temperature, concentrated under reduced pressure, and the product was purified by column chromatography to obtain a light yellow solid with a yield of 80%.

Embodiment 2

[0029] Embodiment 2: N-benzyl-4-methylbenzenesulfonamide: add 1 mmol of 4-methylbenzenesulfonamide in the reaction vessel, add ferric chloride 2 mmol, cuprous chloride 0.1mmol, potassium carbonate in sequence 0.01mmol, toluene 4mL, dimethylformamide (DMF) 3ml. Placed in a microwave reactor and heated to 120 °C under 150 W power for continuous reaction for 30 min. After the reaction was completed, it was cooled to room temperature, concentrated under reduced pressure, and the product was purified by column chromatography to obtain a light yellow solid with a yield of 78%.

Embodiment 3

[0030] Example 3: N-benzyl-4-ethylbenzenesulfonamide: add 1 mmol of 4-ethylbenzenesulfonamide to the reaction vessel, add 2 mmol of ferric chloride, 0.1 mmol of cuprous chloride, and potassium carbonate in sequence 0.01mmol, toluene 4mL, dimethylformamide (DMF) 3ml. Placed in a microwave reactor and heated to 120 °C under 150 W power for continuous reaction for 30 min. After the reaction was completed, it was cooled to room temperature, concentrated under reduced pressure, and the product was purified by column chromatography to obtain a light yellow solid with a yield of 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com