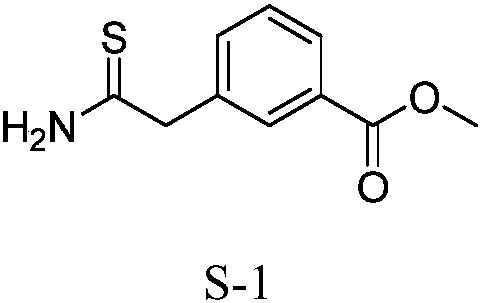

The synthetic method of 3-(2-amino-2-thioethyl) methyl benzoate

A technology for methyl cyanomethylbenzoate and methyl benzoate, which is applied in the field of synthesizing methyl 3-benzoate, can solve the problems of strong organic weak acid odor, influence on catalytic effect, volatile secondary amine, etc., and achieve high product quality , The effect of fast reaction rate and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

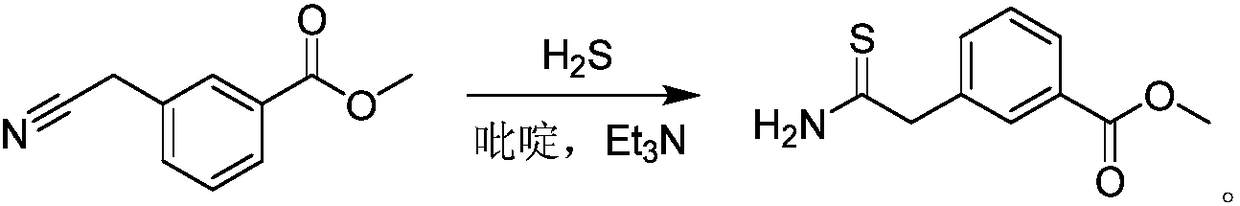

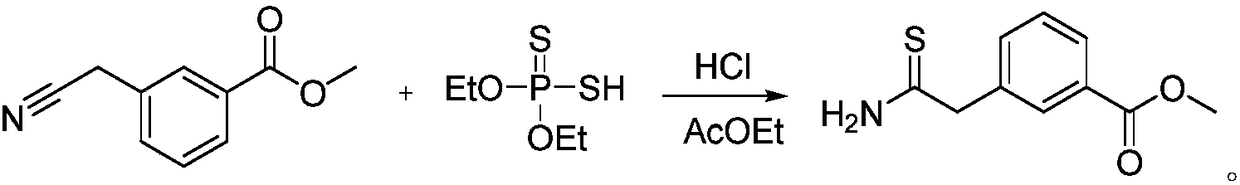

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, a kind of synthetic method of 3-(2-amino-2-thioethyl) methyl benzoate, carry out following steps successively:

[0050] 1), add 3-cyanomethylbenzoic acid methyl ester 35.3g (99.2wt%, 0.2mol), 70wt% (mass %) NaSH (24.0 g, 0.3mol) and methanol 80ml, the water bath was heated to about 70±5°C, under the condition of mechanical stirring, slowly added dropwise the methanol solution (200ml) of triethylamine hydrochloride (41.3g, 0.3mol), the addition time was 6h, continue to stir for 1h after the addition, stop the reaction (the reaction process is tracked and detected by HPLC, when the remaining raw material is less than 1%, stop the reaction).

[0051]2), after the reaction finishes, filter; Filter residue is NaCl, thereby realizes removing the NaCl that reaction generates; The filtrate is distilled (distillation temperature is respectively 68 ℃ and 90 ℃) thereby reclaims methanol (250ml) and triethylamine (38ml, about 0.27mol), the residue after distillation ...

Embodiment 2

[0052] Embodiment 2, a kind of synthetic method of 3-(2-amino-2-thioethyl) methyl benzoate, carry out following steps successively:

[0053] 1), add 3-cyanomethylbenzoic acid methyl ester 35.3g (99.2wt%, 0.2mol), 70wt% NaSH (24.0g, 0.28mol) in the 500ml four-neck flask that thermometer, reflux condenser and stirrer are equipped ) and methanol 80ml, the water bath temperature was raised to about 70±5°C, under the condition of mechanical stirring, slowly dropwise the methanol solution (200ml) of di-n-propylamine hydrochloride (38.5g, 0.28mol), the feeding time was 6h, and the feeding was finished After that, the stirring was continued for 1 h, and the reaction was stopped (the reaction process was tracked and detected by HPLC, and when the remaining raw material was less than 1%, the reaction was stopped).

[0054] 2), after the reaction is finished, filter; remove the NaCl generated by the reaction, distill the filtrate so as to reclaim methanol and di-n-propylamine, the still ...

Embodiment 3

[0055] Embodiment 3, a kind of synthetic method of 3-(2-amino-2-thioethyl) methyl benzoate, carries out following steps successively:

[0056] 1), add 3-cyanomethylbenzoic acid methyl ester 35.3g (99.2wt%, 0.2mol), 70wt% NaSH (24.0g, 0.3mol) in the 500ml four-necked flask that thermometer, reflux condenser and stirrer are equipped with ) and methanol 80ml, the temperature of the water bath was raised to about 70±5°C, under the condition of mechanical stirring, the methanol solution (200ml) of diisopropylamine hydrochloride (41.3g, 0.3mol) was slowly added dropwise, the feeding time was 6h, and the feeding was completed After that, the stirring was continued for 1 h, and the reaction was stopped (the reaction process was tracked and detected by HPLC, and when the remaining raw material was less than 1%, the reaction was stopped).

[0057] 2), after the reaction is finished, filter; remove the NaCl generated by the reaction, distill the filtrate to recover methanol and diisoprop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com