Mechanical preparation method of aromatic polyimide porous material

A porous material, polyimine technology, applied in the field of mechanical preparation of aromatic polyimide porous materials, can solve the problems of long reaction time and high energy consumption, and achieve the effect of short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

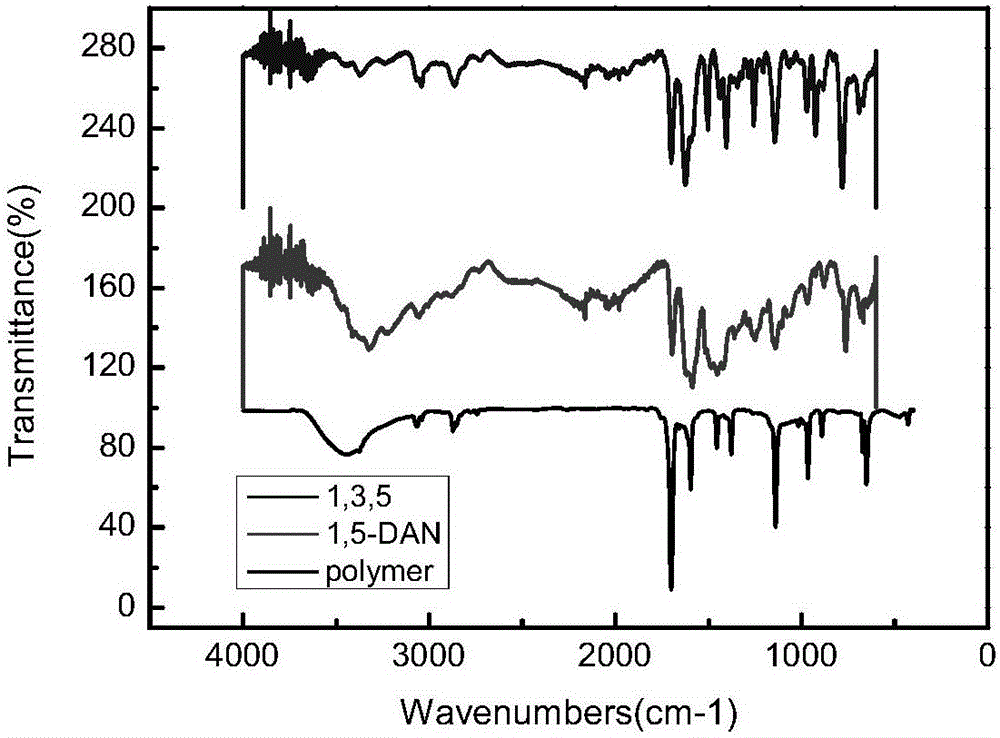

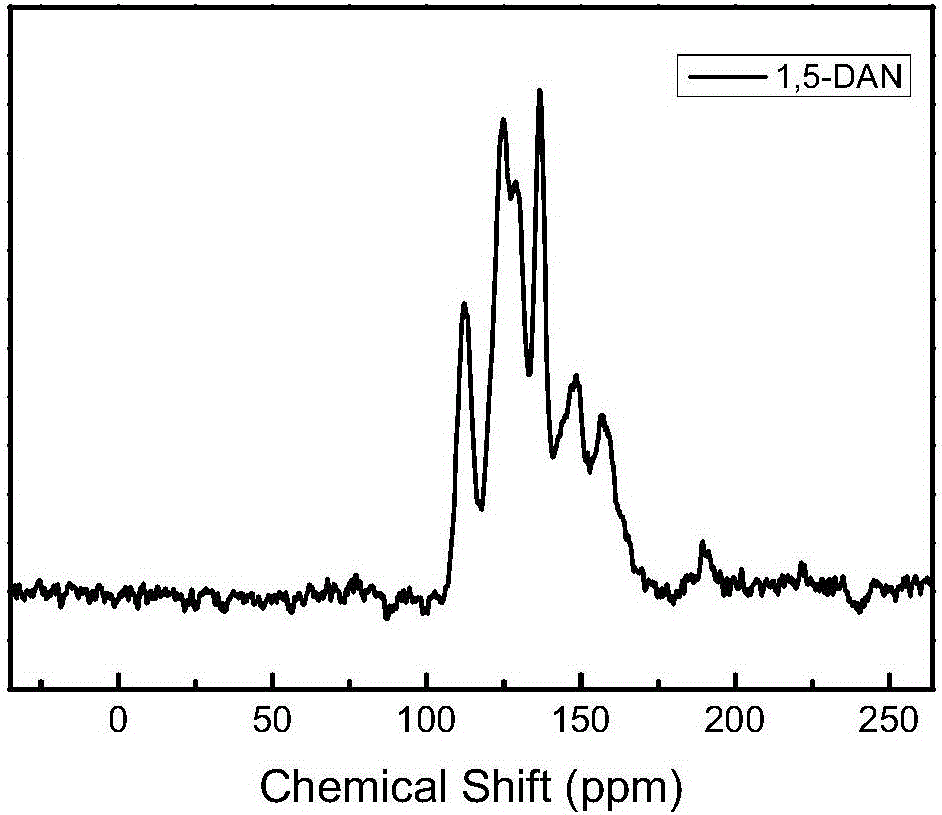

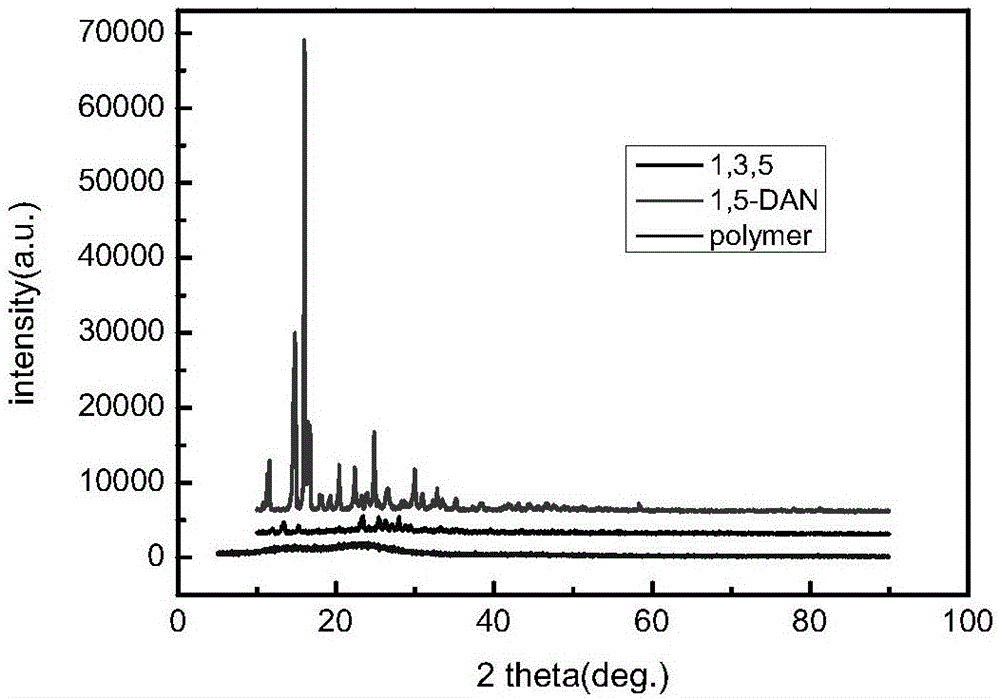

Embodiment 1

[0040] Place two monomers of trimesic aldehyde (81.07mg, 0.5mmoL) and 1,5-naphthalenediamine (118.65mg, 0.75mmoL) in an agate mortar (75mm inner diameter), and add dimethylformamide and Each 0.2 mL of 6 mol / L acetic acid solution was then ground at room temperature using a pestle. After grinding, it was washed with anhydrous acetone in a Soxhlet extraction device for 48 hours to remove unreacted raw materials and oligomers. Finally, it was dried in a vacuum oven at 50°C for two days to obtain an aromatic polyimide porous material. . The yield is 28.5%, and the BET specific surface area is 5.7m 2 / g.

Embodiment 2

[0042] Put the two monomers of trimesic aldehyde (81.07mg, 0.5mmoL) and p-phenylenediamine (81.11mg, 0.75mmoL) in an agate mortar (75mm inner diameter), and add dimethylformamide and 6mol / L dropwise The acetic acid solution was 0.2 mL each, and then ground at room temperature using a pestle. After grinding, it was washed with anhydrous acetone in a Soxhlet extraction device for 48 hours to remove unreacted raw materials and oligomers. Finally, it was dried in a vacuum oven at 50°C for two days to obtain an aromatic polyimide porous material. . The yield is 38.6% and the BET specific surface area is 15.4m 2 / g.

Embodiment 3

[0044] Put the two monomers of trimesic aldehyde (81.07mg, 0.5mmoL) and m-phenylenediamine (81.11mg, 0.75mmoL) in an agate mortar (75mm inner diameter), and add dimethylformamide and 6mol / L dropwise The acetic acid solution was 0.2 mL each, and then ground at room temperature using a pestle. After grinding, it was washed with anhydrous acetone in a Soxhlet extraction device for 48 hours to remove unreacted raw materials and oligomers. Finally, it was dried in a vacuum oven at 50°C for two days to obtain an aromatic polyimide porous material. . The yield is 41.9%, and the BET specific surface area is 30m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com