Preparation method of wear-resistant heat-conducting irradiation-crosslinking ultra-high molecular weight polyethylene

A technology of ultra-high molecular weight and polyethylene, applied in the field of engineering plastic materials, can solve problems such as shape change, poor thermal conductivity, affecting product quality and production efficiency, etc., to improve heat resistance and mechanical strength, ensure basic performance, radiation Dose Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

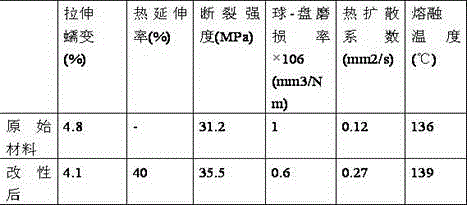

Embodiment 1

[0027] The preparation steps of the wear-resistant and heat-conductive irradiation cross-linked ultra-high molecular weight polyethylene material of the present invention are as follows: using ultra-high molecular weight polyethylene pellets with a molecular weight of about 2 million as raw materials, adding 8wt% of heat-conducting fillers, Boron nitride (BN), 0.5wt% wear-resistant filler, carbon nanotubes (CNT), 1wt% multifunctional crosslinking accelerator triallyl isocyanurate (TAIC), and 0.lwt% antioxidant 4,4'-Thiobis(6-tert-butyl-3-methylphenol), after being fully mixed, sent to the extruder, heated and melted, then extruded from the extruder. During the heating process, the temperature and pressure of the raw materials are controlled, and the thickness of the extruded material is kept at 1-10mm. The obtained sample was irradiated with cobalt source gamma rays in air, the irradiation dose was 100 kGy, and the dose rate was 5 kGy / h. The irradiated sample is placed in an ...

Embodiment 2

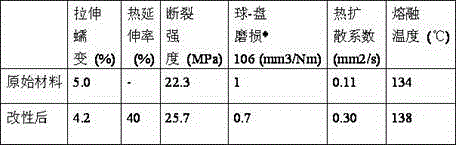

[0032] The preparation steps of the wear-resistant and heat-conductive irradiation cross-linked ultra-high molecular weight polyethylene material of the present invention are as follows: using ultra-high molecular weight polyethylene pellets with a molecular weight of about 3 million as raw materials, adding 6wt% of heat-conducting fillers, Boron nitride (BN), 1wt% wear-resistant filler, carbon nanotubes (CNT), 1.5wt% multifunctional crosslinking accelerator triallyl cyanurate (TAC), and 0.3wt% antioxidant 4, 4′-Thiobis(6-tert-butyl-3-methylphenol), mixed thoroughly, sent to extruder, heated and melted, extruded by extruder. During the heating process, the temperature and pressure of the raw materials are controlled, and the thickness of the extruded material is kept at 1-10mm. The obtained samples were irradiated with high-energy electron beams in air, the irradiation dose was 100kGy, and the dose rate was 440000kGy / h. The irradiated samples were annealed in constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com