A kind of colored floor material and its preparation method and laying method

A floor material and color technology, which is applied to epoxy resin coatings, polyurea/polyurethane coatings, floors, etc., can solve problems such as the floor is easy to appear, not environmentally friendly, and the production process is complicated, so as to achieve high production efficiency and excellent conditions Mild, easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

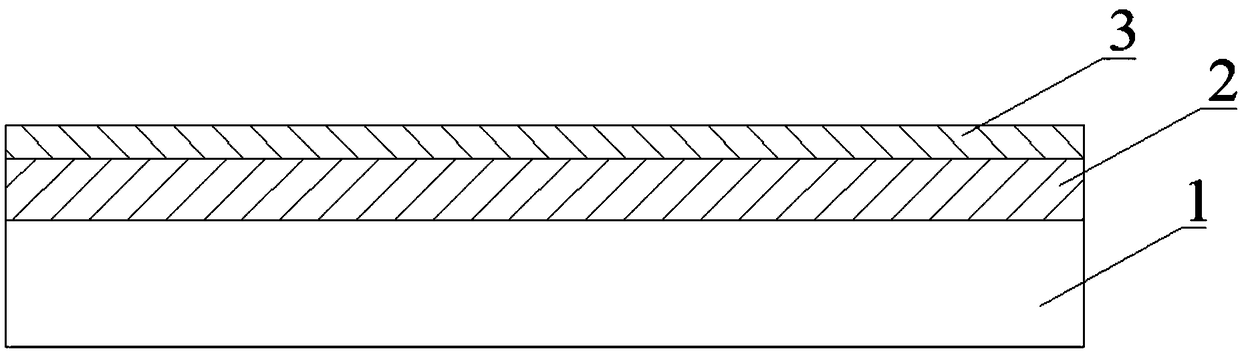

[0028] The present embodiment provides a kind of colored floor material, and it comprises color self-leveling primer and colored self-leveling paint layer sequentially from bottom to top, wherein said colored self-leveling primer is by weight, comprises the following components: 52.5 grade white cement 45 parts; 30 parts of waste sand with a particle size of 100 mesh; 15 parts of granite colored stone powder with a particle size of 800 mesh; 0.3 part of silicone type leveling agent; 0.1 part of fumed silica thixotropic agent; 0.2 part of low-viscosity cellulose; rosin resin 0.1 part of air-entraining agent; 0.5 part of acrylic binder, wherein the silicone type leveling agent is silicone oil, the low-viscosity cellulose is hydroxypropyl methylcellulose with a viscosity of 5-10000, and the granite color stone powder Color can be selected according to actual needs. In terms of mass percentage, the waste sand contains 10% Al 2 (CO 3 ) 3 , which plays a role in improving the wea...

Embodiment 2

[0033] The present embodiment provides a kind of colored floor material, and it comprises color self-leveling primer and colored self-leveling paint layer sequentially from bottom to top, wherein said colored self-leveling primer is by weight, comprises the following components: 52.5 grade white cement 50 parts; 25 parts of waste sand with a particle size of 1000 mesh; 25 parts of granite colored stone powder with a particle size of 1000 mesh; 0.1 part of acrylate type leveling agent; 0.2 part of hydrogenated castor oil thixotropic agent; 0.1 part of low-viscosity cellulose; 0.2 parts of acid air-entraining agent; 0.1 part of acrylic binder, wherein the silicone type leveling agent is silicone oil, the low-viscosity cellulose is hydroxypropyl methylcellulose with a viscosity of 5-10000, and the granite colored stone powder The colors can be selected according to actual needs. In terms of mass percentage, the waste sand contains 10% Al 2 (CO 3 ) 3 , which plays a role in imp...

Embodiment 3

[0038] The present embodiment provides a kind of colored floor material, and it comprises color self-leveling primer and colored self-leveling paint layer sequentially from bottom to top, wherein said colored self-leveling primer is by weight, comprises the following components: 52.5 grade white cement 48 parts; 28 parts of waste sand with a particle size of 950 mesh; 20 parts of granite colored stone powder with a particle size of 900 mesh; 0.2 part of silicone type leveling agent; 0.15 part of fumed silica thixotropic agent; 0.15 part of low viscosity cellulose; fatty alcohol 0.15 parts of sulfonate air-entraining agent; 0.3 parts of acrylic adhesive, wherein the silicone type leveling agent is polyether polyester modified organosiloxane, and the low-viscosity cellulose is hydroxypropyl cellulose with a viscosity of 5-10000 base methyl cellulose, the color of the granite colored stone powder can be selected according to actual needs. In terms of mass percentage, the waste sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com