Waterborne epoxy flash-rust preventing paint

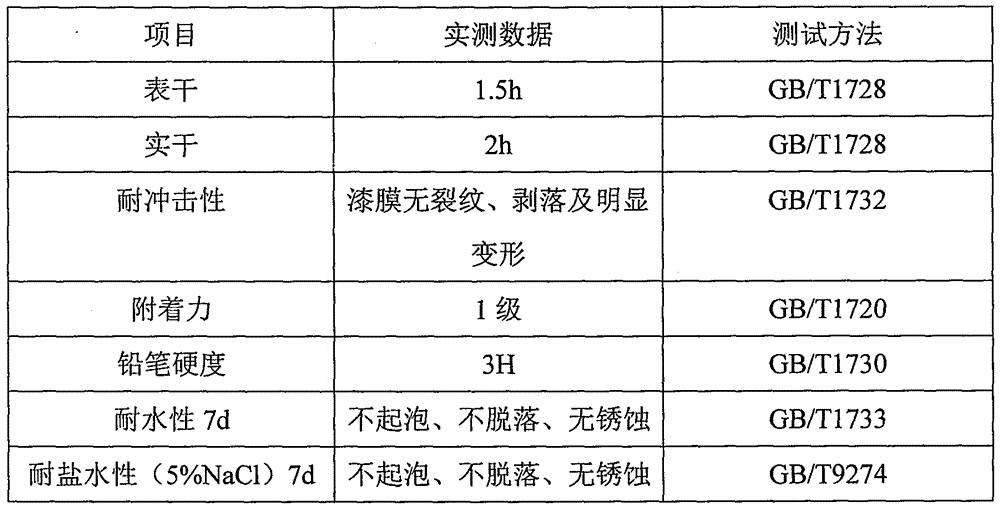

A water-based epoxy and anti-flash rust technology, which is applied in the fields of chemistry and coatings, can solve the problems of high cost and poor low temperature performance of anti-flash rust paint, and achieve good anti-flash rust ability, reduced resin viscosity, and excellent anti-corrosion performance. Excellent mechanical properties Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

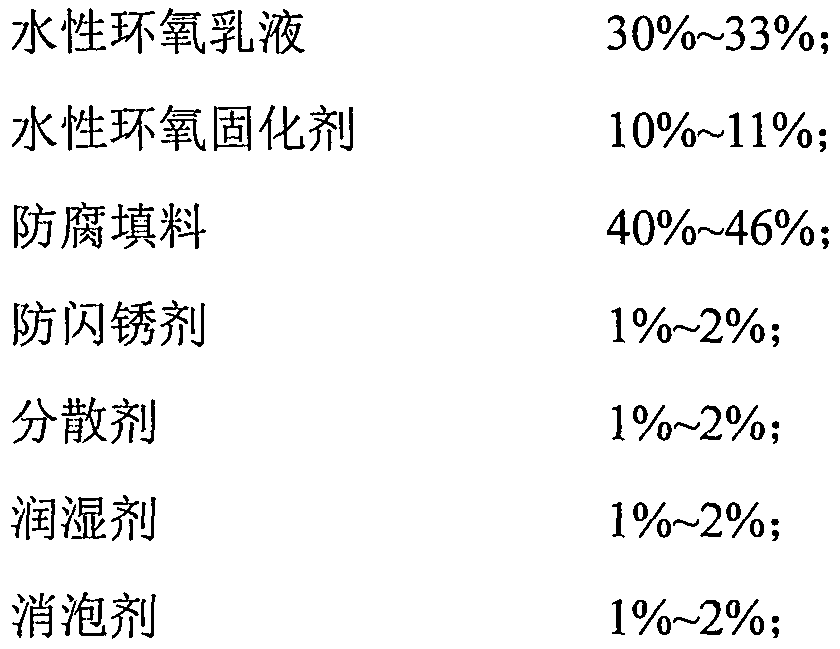

[0020] The invention provides a kind of water-based epoxy anti-flash rust paint, which takes the following components by weight:

[0021] Water-based epoxy emulsion 99g,

[0022] Water-based curing agent 33g,

[0023] 45g of antiseptic pigments and fillers,

[0024] Anti-flash rust agent 2g,

[0025] Defoamer 0.1g,

[0026] Dispersant 0.1g,

[0027] Wetting agent 0.1g,

[0028] Wax powder 1g, mix the above components and stir evenly to get water-based epoxy anti-flash rust paint.

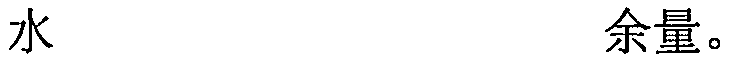

[0029] Further, the structural formula of described waterborne epoxy curing agent is as follows:

[0030] or Alternatively, R is polyethylene polyamine, m-phenylenediamine or m-xylylenediamine.

[0031] Further, the water-based epoxy emulsion is composed of bisphenol A epoxy resin, emulsifier, water, and surfactant, and the mass ratio of bisphenol A epoxy resin, emulsifier, water, and surfactant is 10 :1:10:1.

[0032] Further, the anti-corrosion filler is one or more of zinc powder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com