A continuous process for preparing high-quality needle coke from heavy oil

A technology of needle coke and heavy oil, applied in the continuous process field, can solve the problems of poor quality of needle coke and complex needle coke process, etc., and achieve the effect of less ash, good conductivity and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

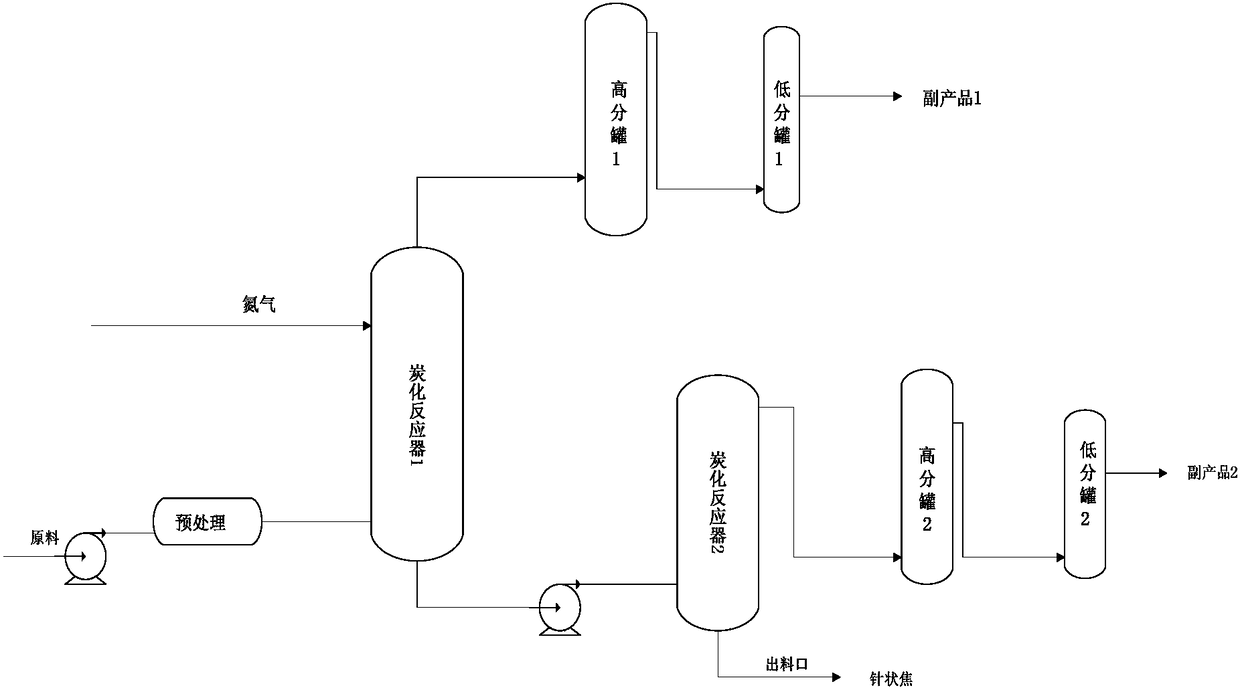

Image

Examples

Embodiment 1

[0022] Use dimethyl sulfoxide to extract the heavy fraction of FCC oil slurry to obtain aromatic-rich components with a molecular weight of 350-500, add them to the carbonization reactor 1, and blow nitrogen to purge and replace the air with a flow rate of 2 L / min. After sweeping 3 times, the temperature was raised to 480°C at a constant speed of 2°C / min. Under nitrogen conditions, the pressure was 3Mpa, and the reaction was carried out for 1h. The heavy components in the carbonization reactor 1 were added to the carbonization reactor 2. At 420°C, react for 7 hours to obtain needle coke with a true density of 2.10g·cm -3 , thermal expansion coefficient 1.5×10 -6 / °C, the ash content is 0.01%.

[0023] The true density is measured by the method of GB / T2540-81 (88); the coefficient of thermal expansion (CTE) is tested by the method of the national standard GB3074-5-82.

Embodiment 2

[0025] Use the four-line cut fraction of dimethyl sulfoxide naphthenic crude oil to extract and obtain the aromatic-rich component with a molecular weight of 350-500, add it to the carbonization reactor 1, and feed nitrogen to purge and replace the air with a flow rate of 2L / min. After purging 3 times, the temperature was raised to 490°C at a constant rate of 2°C / min. Under nitrogen conditions, the pressure was 2Mpa, and the reaction was 2h. The heavy components in the carbonization reactor 1 were added to the carbonization reactor 2. At a pressure of 2Mpa, At a temperature of 420°C, react for 8 hours to obtain needle coke with a true density of 2.30 g·cm -3 , thermal expansion coefficient 1.7×10 -6 / °C, the ash content is 0.02%.

Embodiment 3

[0027] Use dimethyl sulfoxide to extract the deasphalted oil of naphthenic vacuum residue oil to obtain aromatic-rich components with a molecular weight of 350-500, add them to carbonization reactor 1, and blow nitrogen to purge and replace the air with a flow rate of 2L / min, after purging 3 times, the temperature was raised to 500°C at a constant speed of 2°C / min, under nitrogen condition, with a pressure of 3Mpa, and reacted for 3h, the heavy components in the carbonization reactor 1 were added to the carbonization reactor 2. Pressure 1Mpa, temperature 450°C, react for 10h to obtain needle coke with a true density of 2.15g·cm -3, , thermal expansion coefficient 1.8×10 -6 / ℃, ash content 0.01%

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com