Kitchen oil cleaning agent

A kind of oil cleaning agent and kitchen technology, which is applied in the field of daily chemistry, can solve the problems of strong corrosion, skin irritation, human body and environmental hazards, etc., and achieve the effect of strong anti-corrosion ability, safe and convenient use, and strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

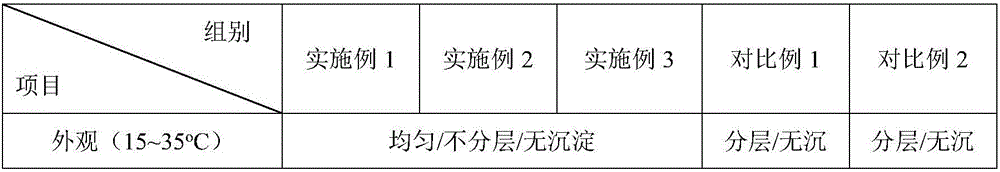

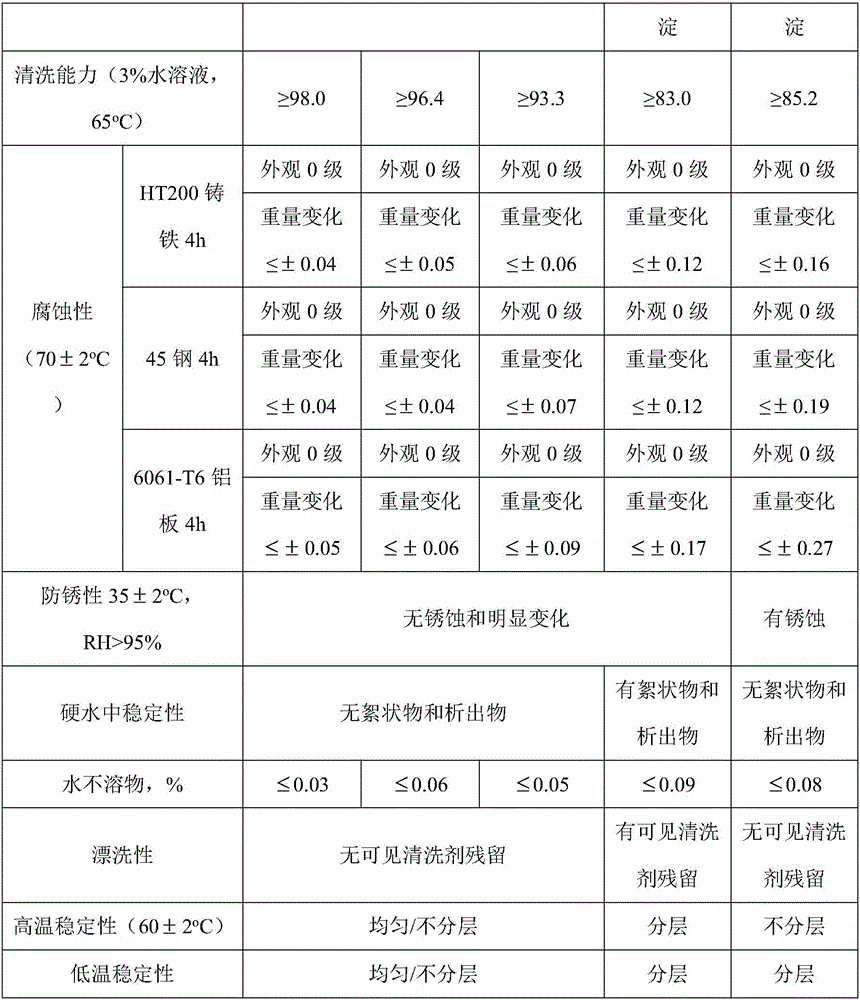

Examples

Embodiment 1

[0031] Embodiment 1 a kind of kitchen grease cleaning agent

[0032] A kind of kitchen grease cleaning agent, is made up of the following components by weight percentage: α-alkenyl sodium sulfonate 15%, fatty alcohol polyoxyethylene ether sodium sulfate 20%, triethylene glycol butyl ether 12%, coconut acid diethanolamine condensate 7.5%, Sodium Gluconate 2.5%, Sodium Xylene Sulfonate 1.5%, Triethanolamine 2.5%, Sodium Metasilicate Nonahydrate 0.2%, Lemon Eucalyptus Oil 0.4%, Titanium Dioxide 2.4%, Sodium Dichloroisocyanurate 1% and Water 35%.

[0033] The preparation method is the same as the preparation method of general cleaning agents. The raw materials are accurately weighed, dissolved in water, and stirred evenly to obtain the product.

Embodiment 2

[0034] Embodiment 2 A kind of kitchen greasy dirt cleaning agent

[0035] A kind of cleaning agent for kitchen oil stains, mainly composed of the following ingredients in weight percentage: 6% sodium α-alkenyl sulfonate, 8% fatty alcohol polyoxyethylene ether sodium sulfate, 10% triethylene glycol butyl ether, condensed diethanolamine coconut acid 5%, sodium gluconate 0.5%, sodium xylene sulfonate 0.1%, triethanolamine 1%, sodium metasilicate nonahydrate 0.1%, oil of lemon eucalyptus 0.3%, titanium dioxide 1%, sodium dichloroisocyanurate 0.5% and water 67.5%.

[0036] The preparation method is similar to Example 1.

Embodiment 3

[0037] Embodiment 3 a kind of kitchen greasy dirt cleaning agent

[0038] A kind of cleaning agent for kitchen oil stains, mainly composed of the following components by weight percentage: 18% of sodium α-alkenyl sulfonate, 24% of fatty alcohol polyoxyethylene ether sodium sulfate, 20% of triethylene glycol butyl ether, condensed diethanolamine coconut acid 10%, sodium gluconate 5%, sodium xylene sulfonate 3%, triethanolamine 3%, sodium metasilicate nonahydrate 0.5%, oil of lemon eucalyptus 0.5%, titanium dioxide 3%, sodium dichloroisocyanurate 1.5% and water 11.5%.

[0039]The preparation method is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com