Tungsten-contained raw ore pretreatment system for realizing green metallurgy

A pretreatment and green technology, applied in the tungsten ore decomposition system and the field of tungsten ore decomposition technology, can solve the problems of high chemical accident rate, no industrial application, complex process flow, etc., to achieve a wide range of applications and achieve no pollution. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

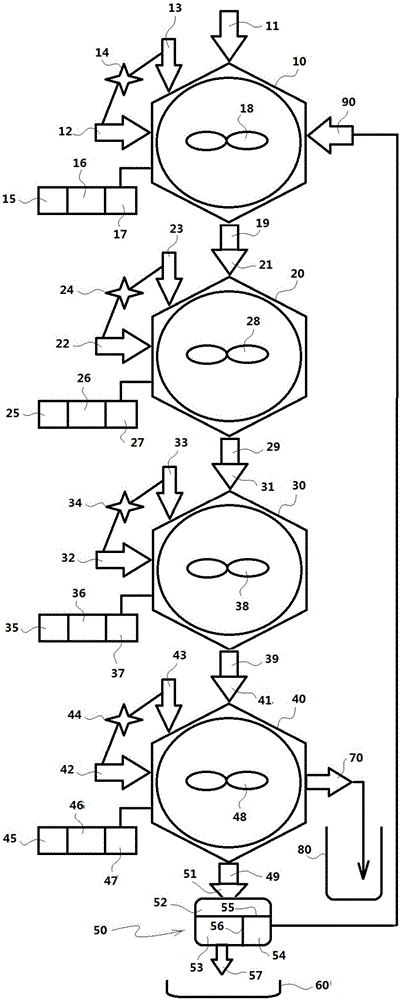

[0051] According to one embodiment of the present invention, the tungsten-containing raw ore pretreatment system for realizing green metallurgy includes:

[0052] The first-stage stripping reaction closed container 10: it has a tungsten ore inlet 11, a high concentration (98%) ammonium phosphate solution inlet 12, a water inlet 13, a mass ratio controller 14 of ammonium phosphate and water, a reaction temperature controller 15, Stirring speed controller 16, reaction time controller 17, stirring paddle 18, first-stage dissolved solid material outlet 19, waste residue feedback inlet 90;

[0053] Second-stage dissolution reaction airtight container 20: it has first-stage dissolution solid material inlet 21, high-concentration (98%) ammonium phosphate solution inlet 22, water inlet 23, mass ratio controller 24 of ammonium phosphate and water, reaction temperature Controller 25, stirring speed controller 26, reaction time controller 27, stirring paddle 28, second-stage dissolved so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com