High-performance fabric for weapons and equipment and preparation method thereof

A high-performance, well-equipped technology, applied in the field of textile fabrics, can solve the problems of low water and oil absorption rate, slow adsorption rate, single function, etc., achieve good antistatic and antibacterial properties, increase adsorption capacity and adsorption rate, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

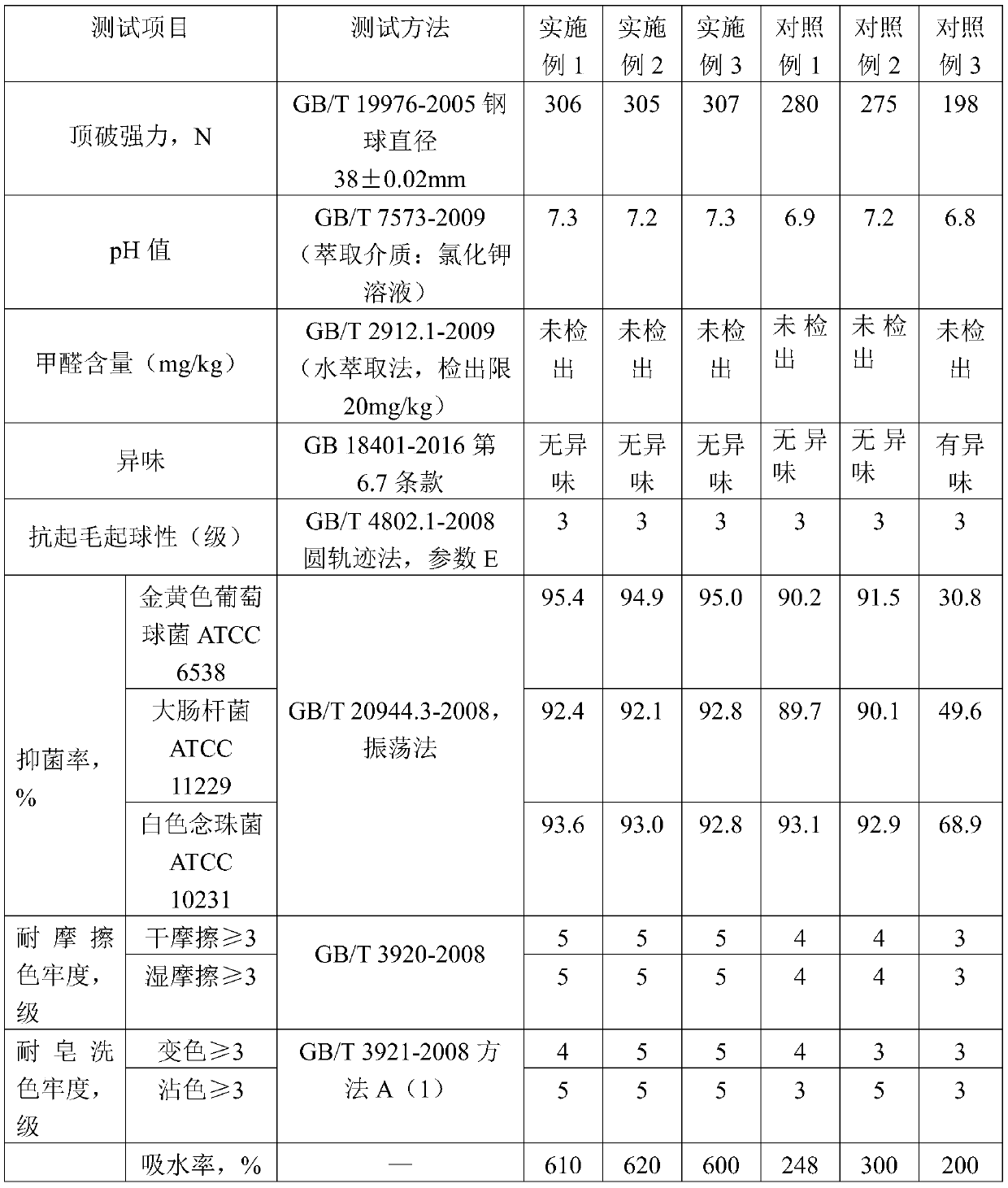

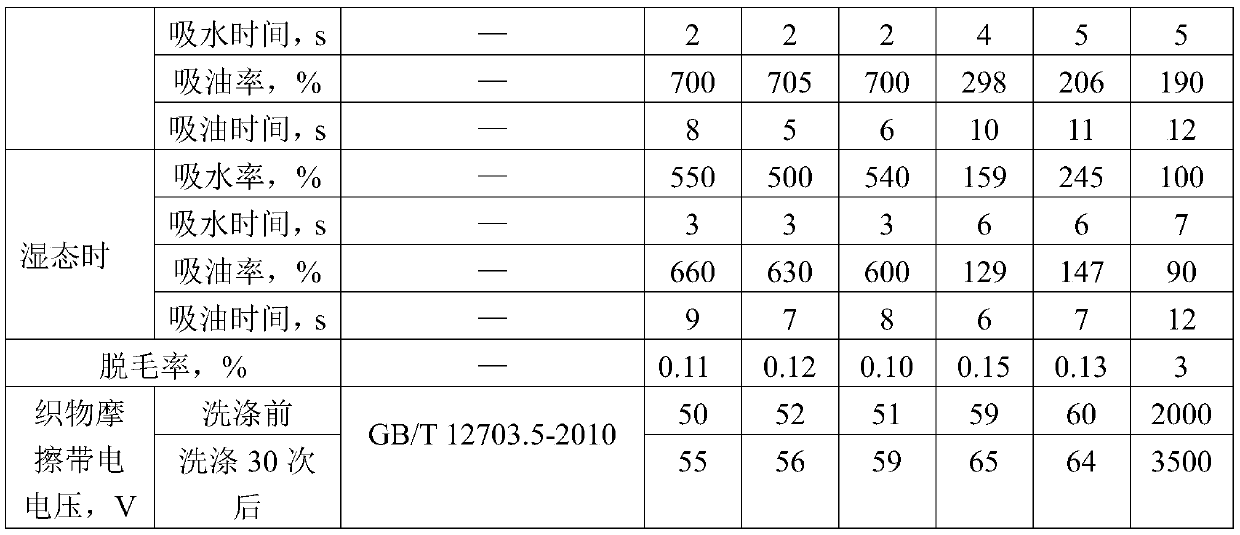

Examples

Embodiment 1

[0026] A method for preparing a special high-performance fabric for weaponry, specifically comprising the following steps:

[0027] Step 1: weaving the hygroscopic functional yarn to obtain gray cloth, bleaching the gray cloth to obtain bleached gray cloth; the functional fiber is long-staple cotton fiber, soybean fiber or corn fiber, and the weaving is knitting, knitting gray cloth It is a knitted plain weave or terry structure; the bleaching process is specifically: according to the water volume, urea peroxide 12g / L, hydrogen peroxide 19mL / L, sodium carbonate 1.0g / L, fatty alcohol polyoxyethylene ether 1.3mL / L, Sodium dodecylsulfonate 1.6g / L was added to the water in turn, stirred evenly, the pH of the solution was adjusted to 9-10, the temperature was raised to 60°C, and the fabric obtained in step 1 was placed in it for bleaching for 60 minutes; bleached gray fabric was obtained;

[0028] Step 2: washing the bleached gray cloth obtained in step 1 once at 55°C to obtain a w...

Embodiment 2

[0036] A method for preparing a special high-performance fabric for weaponry, specifically comprising the following steps:

[0037] Step 1: weaving the hygroscopic functional yarn to obtain gray cloth, bleaching the gray cloth to obtain bleached gray cloth; the functional fiber is long-staple cotton fiber, soybean fiber or corn fiber, and the weaving is knitting, knitting gray cloth It is a knitted plain weave or terry structure; the bleaching process is specifically: according to the water volume, urea peroxide 10g / L, hydrogen peroxide 18mL / L, sodium carbonate 0.8g / L, fatty alcohol polyoxyethylene ether 1.2mL / L, Sodium dodecylsulfonate 1.5g / L was added to water in turn, stirred evenly, the pH of the solution was adjusted to 9-10, the temperature was raised to 60°C, and the fabric obtained in step 1 was placed in it for bleaching for 60 minutes; bleached gray fabric was obtained;

[0038] Step 2: washing the bleached gray cloth obtained in step 1 once at 50°C to obtain a washe...

Embodiment 3

[0046] A method for preparing a special high-performance fabric for weaponry, specifically comprising the following steps:

[0047] Step 1: Step 1: Weaving the hygroscopic functional yarn to obtain a gray cloth, and bleaching the gray cloth to obtain a bleached gray cloth; the functional fiber is long-staple cotton fiber, soybean fiber or corn fiber, and the weaving is knitting , the knitted gray fabric is a knitted plain weave or terry structure; the bleaching treatment is specifically: according to the water volume, urea peroxide 13g / L, hydrogen peroxide 20mL / L, sodium carbonate 1.2g / L, fatty alcohol polyoxyethylene ether 1.5mL / L, sodium dodecylsulfonate 1.7g / L were added to water in turn, stirred evenly, adjusted the pH of the solution to 9-10, raised the temperature to 65°C, placed the fabric obtained in step 1 in it and bleached it for 50min; to obtain bleached gray fabric;

[0048] Step 2: washing the bleached gray cloth obtained in step 1 once at 60°C to obtain a washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com