Bridge support with novel friction pair

A bridge bearing and friction pair technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of complex forming process, low forming efficiency, environmental pollution, etc., and achieve simple forming process, high forming efficiency and low friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

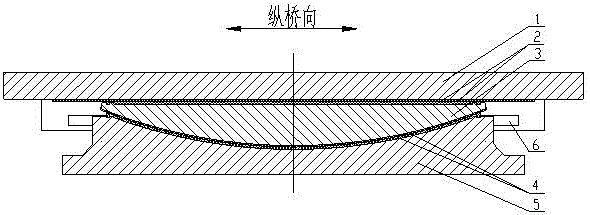

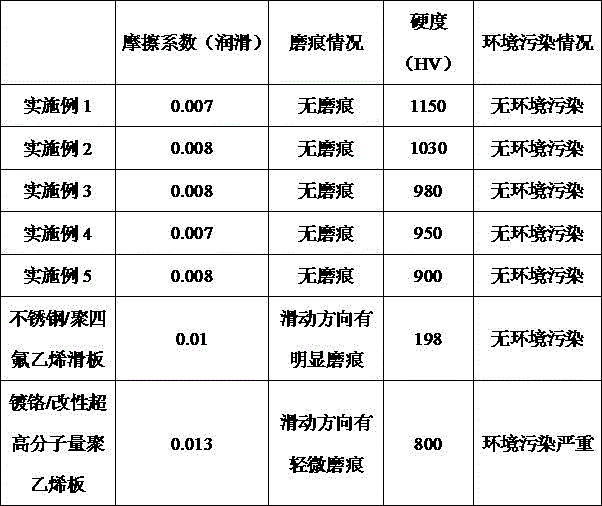

[0025] The friction-reducing, wear-resistant and corrosion-resistant ceramic layer is made of aluminum oxide Al 2 o 3 The content is 80%, titanium dioxide TiO 2 Content 3%, silicon dioxide SiO 2 Content 4%, molybdenum disulfide MoS 2 Made with 10% graphite content and 3% graphite C content. A ceramic layer is formed on the sliding plane of the upper seat plate 1, the rotating curved surface of the middle seat plate 3 and the guide structure 6 by the plasma spraying method, and the thickness of the ceramic layer is 0.5 mm. The ceramic layer on the upper seat plate 1 and the modified ultra-high molecular weight polyethylene form a new plane friction pair 2. The ceramic layer on the middle seat plate 3 and the modified ultra-high molecular weight polyethylene slide plate form a curved surface new friction pair 4. Guide structure and modification The ultra-high molecular weight polyethylene slide plate constitutes the guiding friction pair 6.

[0026] After testing, the frict...

Embodiment 2

[0028] The friction-reducing, wear-resistant and corrosion-resistant ceramic layer is made of aluminum oxide Al 2 o 3 The content is 65%, titanium dioxide TiO 2 Content 13%, silicon dioxide SiO 2 5% content, nano-copper powder Cu content 10%, graphite C content 7%. The plasma spraying method is used to spray on the sliding plane of the upper seat plate 1 and the rotating curved surface of the middle seat plate 3 of the support, and the coating thickness is 1mm. The ceramic layer of the upper seat plate 1 and the polytetrafluoroethylene sliding plate form a flat new friction pair 2. The ceramic layer on the middle seat plate 3 and the polytetrafluoroethylene sliding plate form a curved surface new friction pair 4. The guide structure and the polytetrafluoroethylene sliding plate form a guide Friction pair 6.

[0029] After testing, the friction-reducing, wear-resistant and corrosion-resistant ceramic layer in this embodiment is thermally sprayed directly at the forming posi...

Embodiment 3

[0031] The friction-reducing, wear-resistant and corrosion-resistant ceramic layer is made of aluminum oxide Al 2 o 3 The content is 50%, titanium dioxide TiO 2 Content 25%, silicon dioxide SiO 2 10% content, 5% molybdenum disulfide, 5% graphene content, and 5% nano copper powder content. Utilize the plasma spraying method to spray on the sliding plane of the upper seat plate 1 and the rotating curved surface of the middle seat plate 3 on the support, and the coating thickness is 1.2mm. The ceramic layer of the upper seat plate 1 and the polytetrafluoroethylene sliding plate form a flat new friction pair 2. The ceramic layer on the middle seat plate 3 and the polytetrafluoroethylene sliding plate form a curved surface new friction pair 4. The guide structure and the polytetrafluoroethylene sliding plate form a guide Friction pair 6.

[0032] After testing, the friction-reducing, wear-resistant and corrosion-resistant ceramic layer in this embodiment is thermally sprayed di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com