Optical fiber micro-bubble Fabry-Perot sensor and sensing method thereof

A Fab sensor and sensor technology, applied in the field of optical fiber, can solve the problems of high production difficulty, complex production process, high cost, etc., and achieve the effects of integration, flexible control, and fixed-point measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

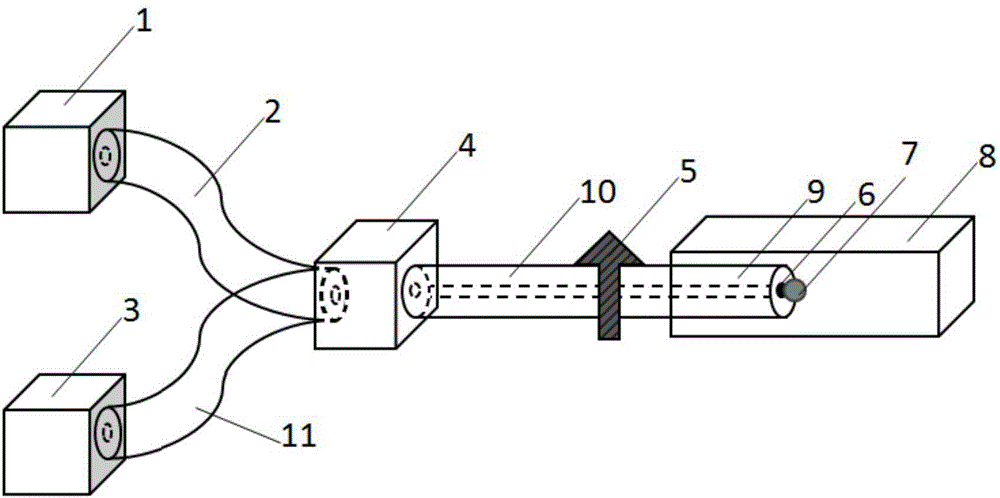

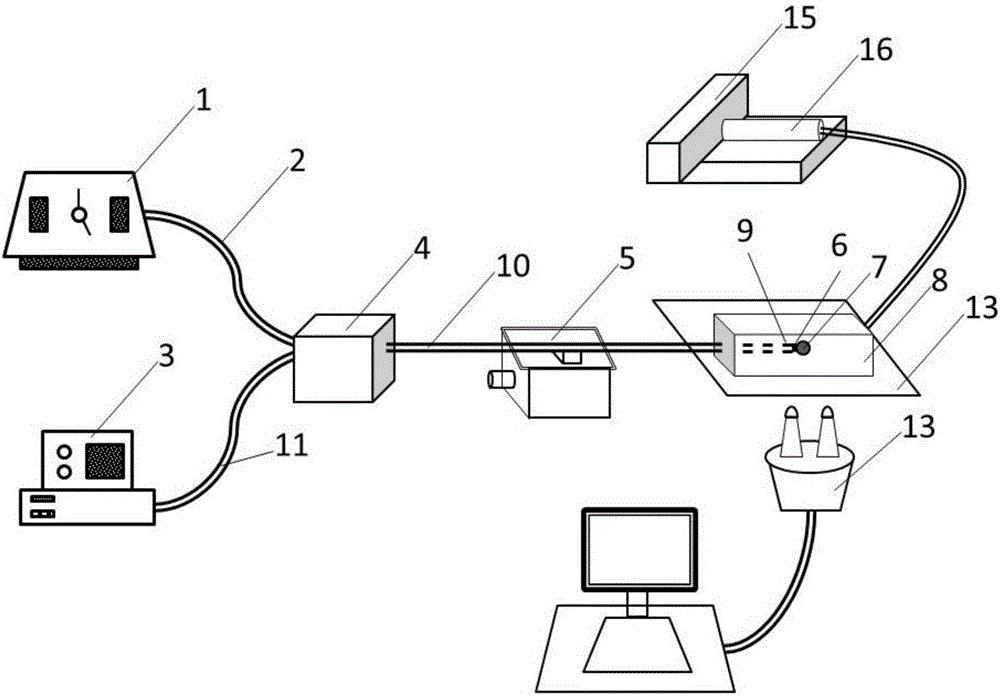

[0027] The sensing device of the fiber optic microbubble Fab sensor provided in this embodiment has a structure such as figure 1 As shown, it includes 980nm laser 1, front section HI 1060 single-mode fiber 2, common single-mode fiber 11, spectrum analyzer 3, wavelength division multiplexer 4, displacement stage 5, microfluidic channel 8 and sensor 9, sensor 9 is composed of The rear section is composed of HI 1060 single-mode fiber and carbon nano-film 6 uniformly deposited on the core of the flat end face of the single-mode fiber.

[0028] Among them, the common single-mode fiber 11 is a single-mode fiber with a central wavelength of 1550nm, the fiber core is very thin, the core diameter is generally 8 to 10um, and the cladding diameter is 125um, which is a commonly used single-mode fiber in the communication band;

[0029] The front section HI 1060 single-mode fiber 2 and the rear section HI 1060 single-mode fiber 10 are single-mode fibers with a center wavelength of 980nm, a...

Embodiment 2

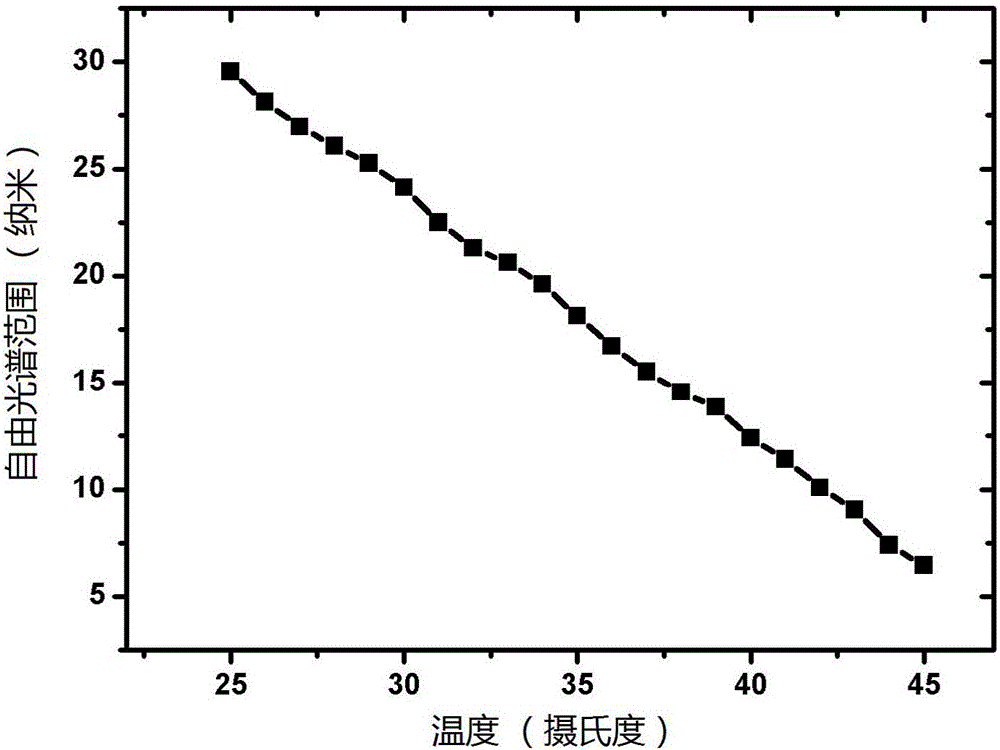

[0035] This embodiment is further limited on the basis of Embodiment 1. The sensor 9 is a uniform carbon nanotube film 6 plated at the core of the end face of the cut flat rear section HI1060 single-mode optical fiber. According to the heat conduction characteristics of carbon nanotubes, Microbubbles 7 are generated in the liquid environment, which is the optical resonant cavity structure for sensing. Most of the probe-type optical fiber sensors in the prior art adopt the method of micromachining on the end face of the optical fiber. The manufacturing process of these methods is complicated and difficult. Preparation time reduces costs.

Embodiment 3

[0037]The present embodiment also provides a method for preparing a Perth cavity sensor based on the microbubble method on the end face of an optical fiber, which specifically includes the following steps:

[0038] Step 1): Cut the end face of the rear section HI 1060 single-mode optical fiber 10 with a cladding diameter of 125um and a core diameter of 5.8um to obtain a flat end face of the optical fiber;

[0039] Step 2): vertically insert the rear HI 1060 single-mode optical fiber 10 into the uniform carbon nanotube solution, and fix it;

[0040] Step 3): Turn on the 980nm laser 1, and adjust the power to 67.5mw. Under this power, slowly pull out the rear HI1060 single-mode fiber 10 vertically from the carbon nanotube solution, that is, finish once on the flat end surface of the fiber. The operation of coating carbon nano film;

[0041] Step 4): Repeat step 3) to perform multiple coating operations on the flat end face of the optical fiber to obtain a sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com