Manufacturing method of semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as low chip yield, white pixel defects, and image noise, and achieve less dislocations and improve signal quality. The effect of noise ratio and good picture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

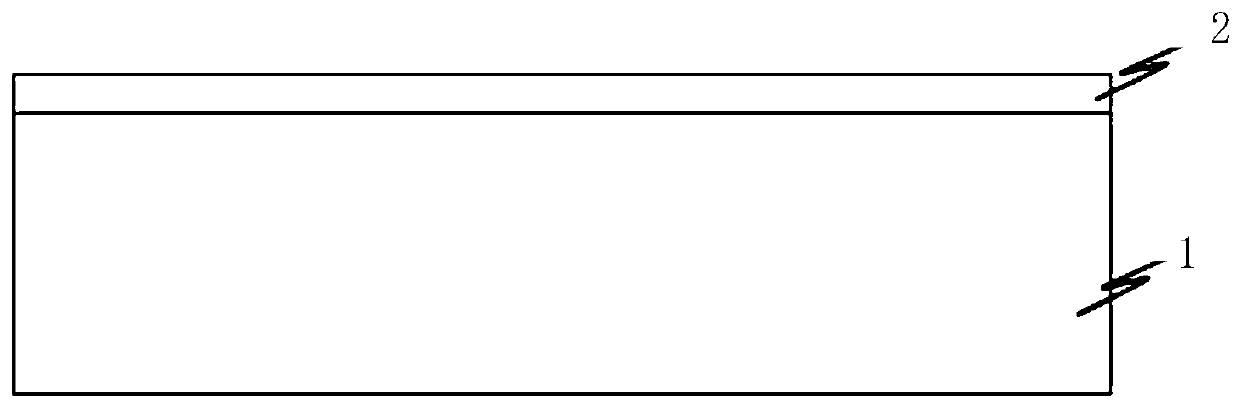

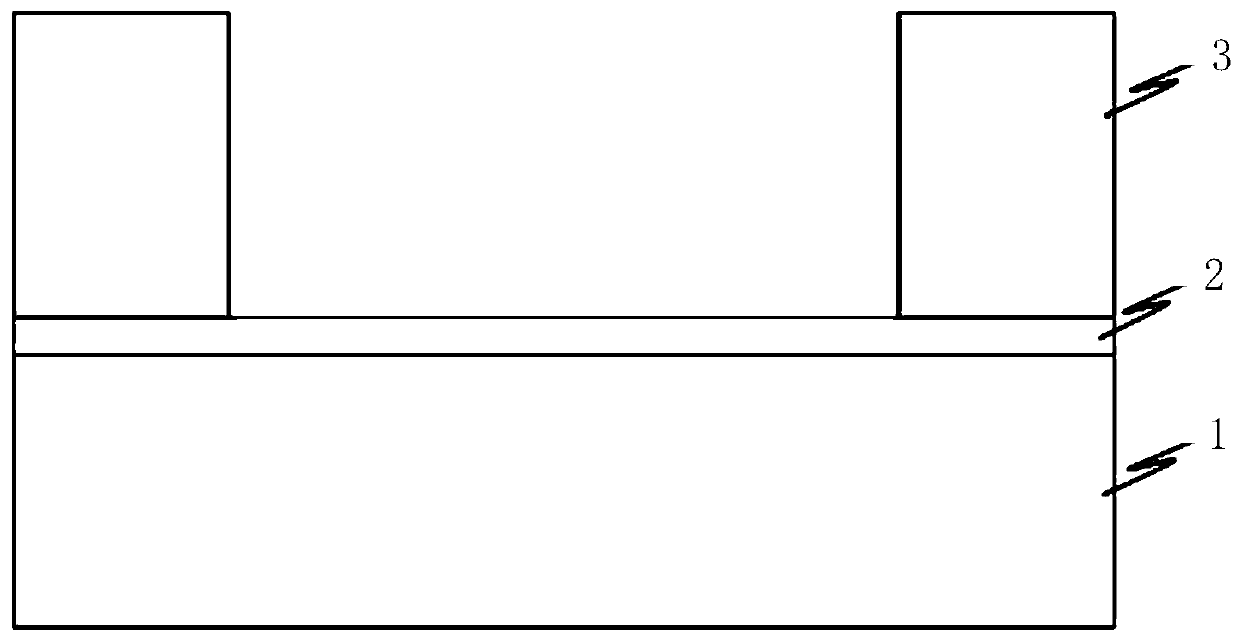

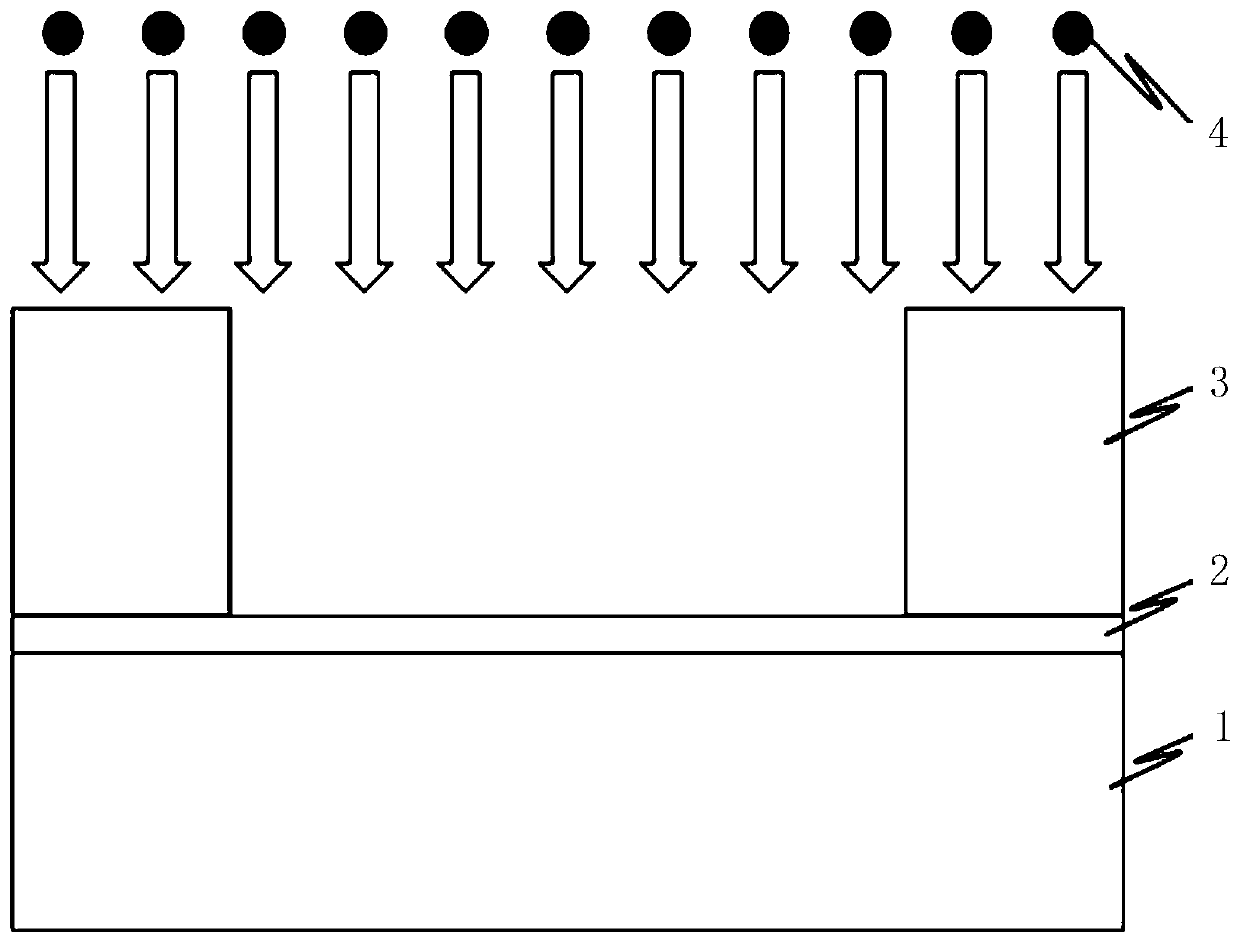

[0030] In the following specific embodiments of the present invention, please refer to Figure 1a ~ Figure 1f , Figure 1a ~ Figure 1f It is a schematic process flow diagram of Embodiment 1 of the present invention. Such as Figure 1a ~ Figure 1f Shown, a kind of manufacturing method of semiconductor device of the present invention comprises the following steps:

[0031] 1) After conventional RCA cleaning of the semiconductor substrate, a silicon dioxide film is formed on the surface of the substrate.

[0032] Such as Figure 1a As shown, in this embodiment, an N-type semiconductor epitaxial wafer with a substrate resistivity of 80-100 Ω·cm and a crystal orientation of (100), such as an epitaxial silicon wafer, can be used as the semiconductor substrate 1 . The present invention is not limited thereto. Firstly, the semiconductor substrate 1 is cleaned by conventional RCA, and the cleaning solution can be SC1, HF, and SC2. Then, a layer of silicon dioxide 2 can be formed ...

Embodiment 2

[0051] In the following specific embodiments of the present invention, please refer to Figure 2a ~ Figure 2f , Figure 2a ~ Figure 2f It is a schematic process flow diagram of Embodiment 2 of the present invention. Such as Figure 2a ~ Figure 2f Shown, a kind of manufacturing method of semiconductor device of the present invention comprises the following steps:

[0052] 1) After conventional RCA cleaning of the semiconductor substrate, a silicon dioxide film is formed on the surface of the substrate.

[0053] Such as Figure 2a As shown, in this embodiment, an N-type semiconductor epitaxial wafer with a substrate resistivity of 80-100 Ω·cm and a crystal orientation of (100), such as an epitaxial silicon wafer, can also be used as the semiconductor substrate 1 . The present invention is not limited thereto. Firstly, the semiconductor substrate 1 is cleaned by conventional RCA, and the cleaning solution can be SC1, HF, and SC2. Then, a layer of silicon dioxide 2 can be fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com