Electrode plate activation method for negative electrode based on passivation metal lithium powder

A passivation metal and activation method technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve problems such as hindering the extraction of metal lithium lithium ions and increasing battery internal resistance, so as to increase electrochemical activity and process Simple and environmentally friendly, the effect of ultra-high electrochemical gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

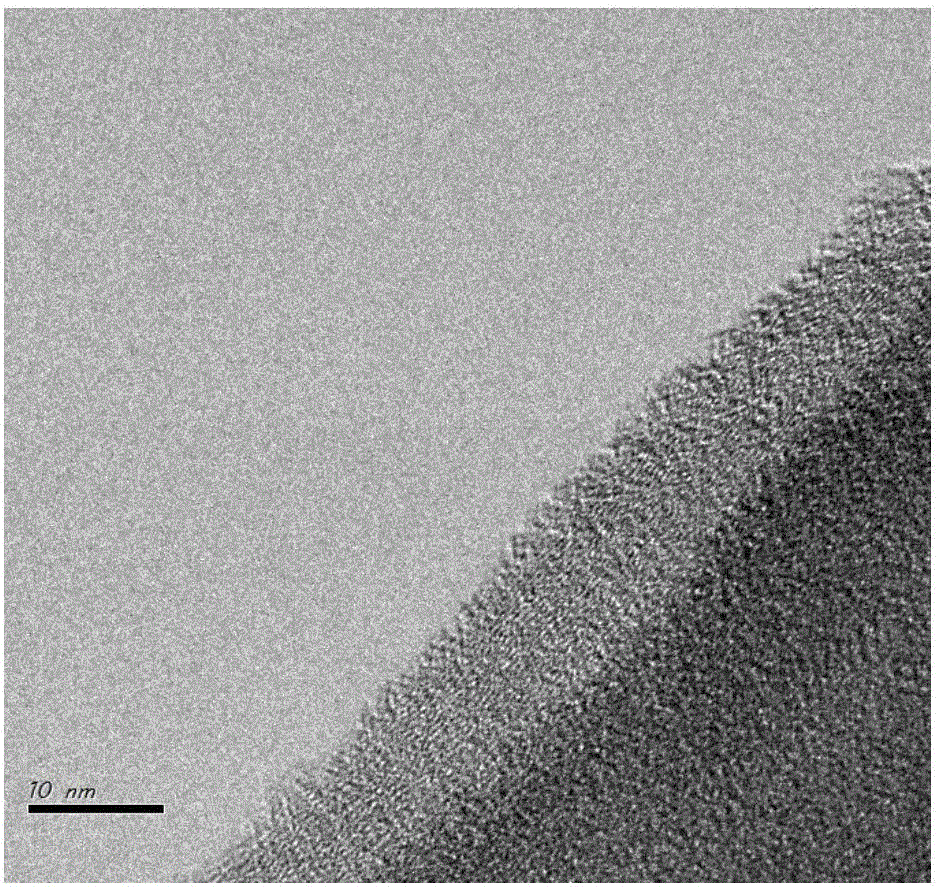

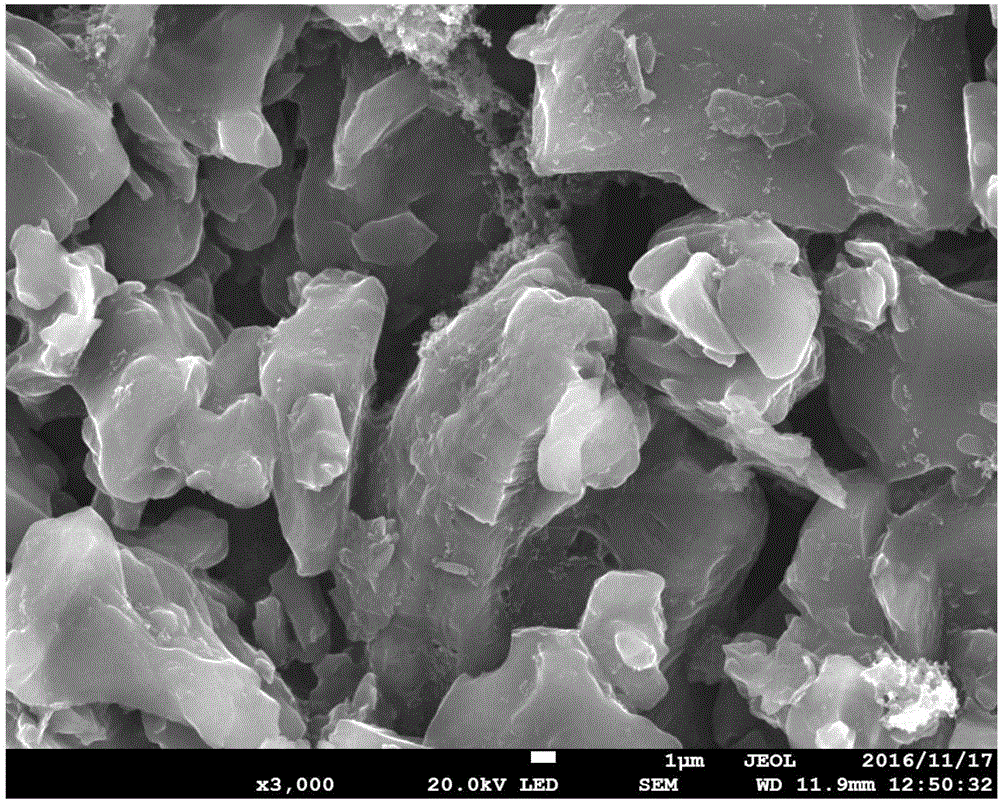

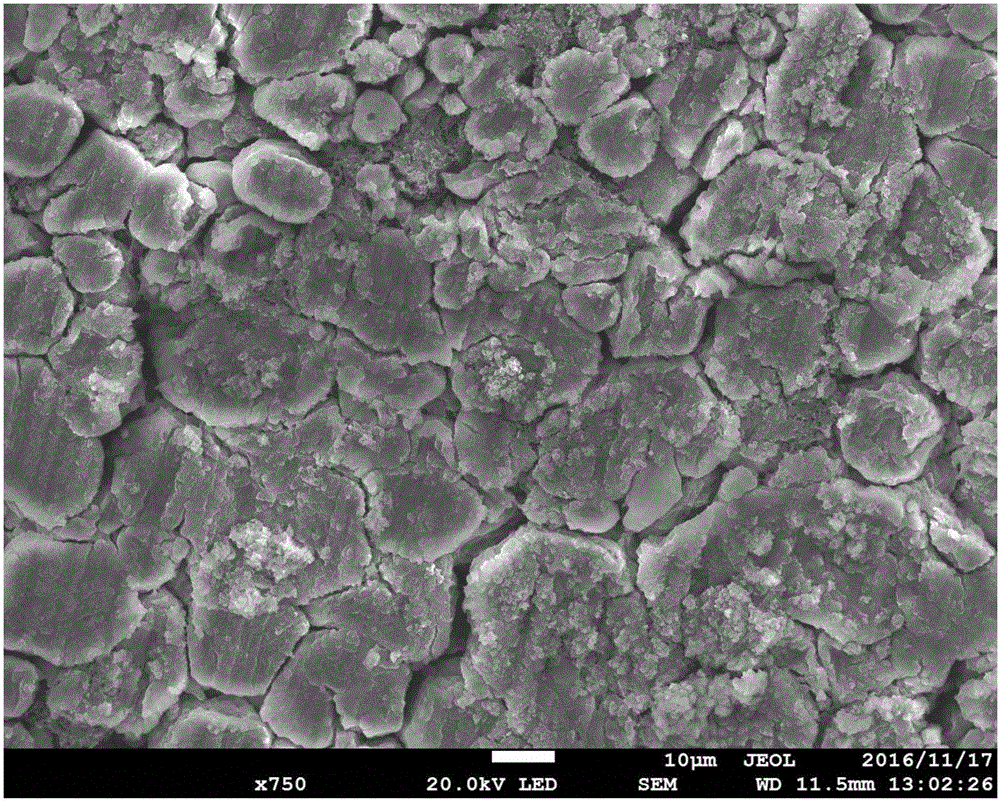

[0022] Example 1, see Figure 1 to Figure 3 :

[0023] The invention provides a method for activating an electrode sheet based on a passivated metal lithium powder negative electrode, comprising the following steps:

[0024] 1) The SBR / toluene solution containing the lithium metal powder with a mass concentration of 2% is uniformly coated on the graphite electrode sheet with the copper sheet as the current collector by a coating machine to obtain the lithium metal powder / graphite / copper electrode sheet;

[0025] 2) Transfer the metal lithium powder / graphite / copper electrode sheet to an argon-protected glove box, dry at 60°C for 4 hours, and set aside;

[0026] 3) Roll the dried metal lithium powder / graphite / copper electrode sheet (total thickness 92 microns) in an argon-protected glove box with a roller press, and control the roll gap of the roller press to 60 microns, so that the lithium metal The powder / graphite / copper electrode sheet passes through the roll gap at a const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com