Composite solid electrolyte membrane, preparation method and lithium-ion battery

A technology of solid electrolyte membrane and electrolyte, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low room temperature conductivity, poor mechanical strength, poor interface compatibility between the membrane and positive and negative electrodes, and improve cycle performance , to ensure the flexibility of the film and enhance the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

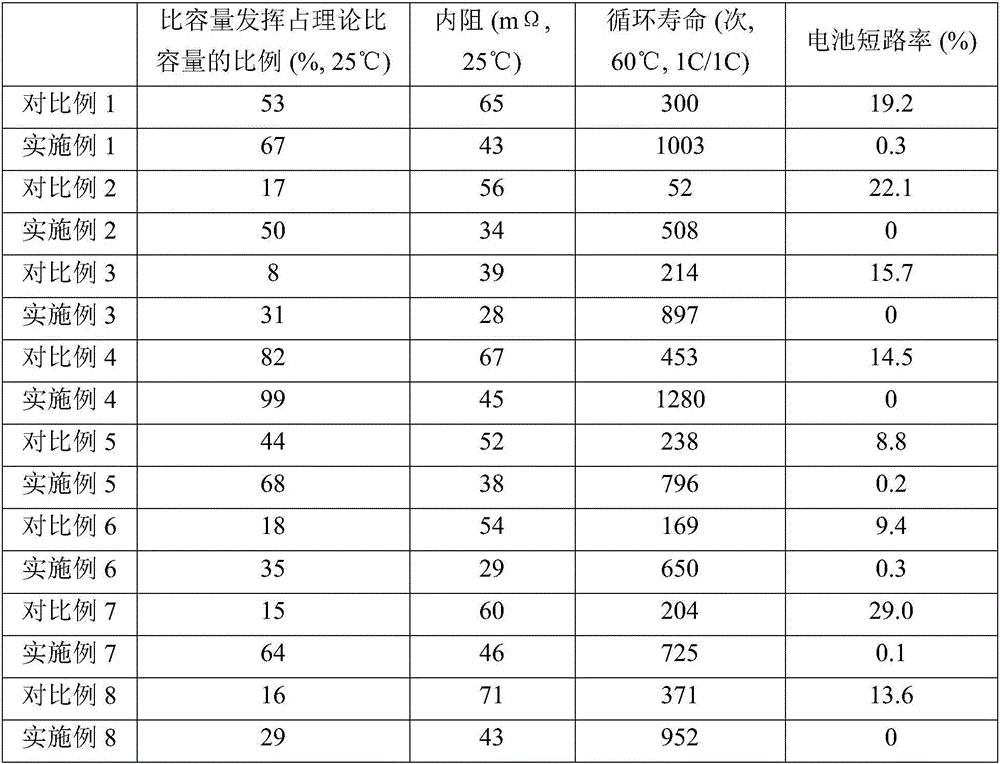

Embodiment 1

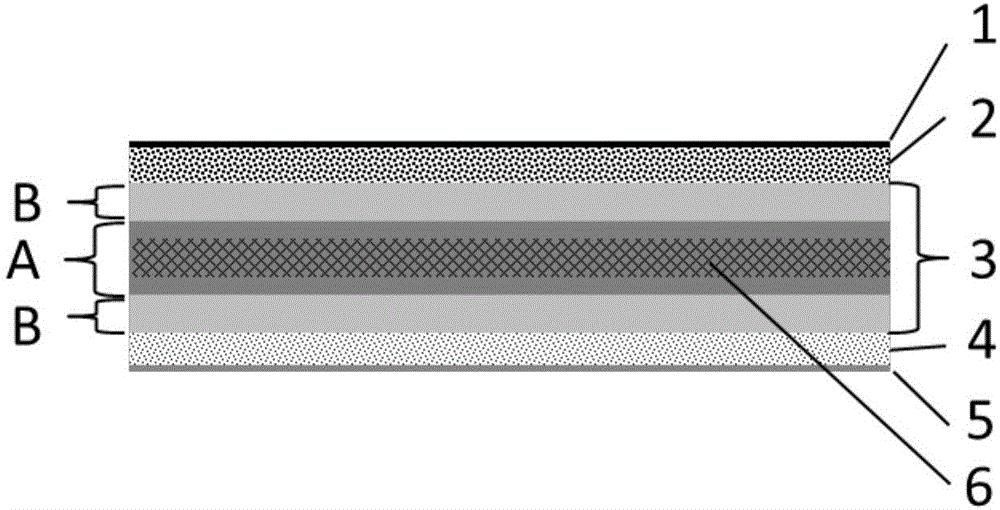

[0042] Dissolve PEO and LiTFSI in acetonitrile according to the ratio of lithium to oxygen ratio of 1:13 to form an organic polymer electrolyte gel with a solid content of 5%, and then add LLTO to mix and disperse to form the first composite gel with an inorganic ratio of 60%; PEO and LiTFSI are dissolved in acetonitrile according to the ratio of lithium to oxygen ratio of 1:18 to form an organic polymer electrolyte gel with a solid content of 6%, and then add lithium, lanthanum, zirconium and oxygen to mix and disperse to form a second composite gel with an inorganic ratio of 10%. ;

[0043] Coating the first composite adhesive on both sides of the glass fiber net, evaporating the solvent at 80°C, and then coating the second composite adhesive on the first composite adhesive layer, and evaporating the solvent at 90°C, to obtain a composite solid electrolyte membrane;

[0044] A solid-state lithium-ion battery is made by using a composite solid electrolyte membrane with a lith...

Embodiment 2

[0050] Copolymer of PEO and PPO with LiClO 4 Dissolve in water according to the ratio of lithium to oxygen ratio 1:40 to form an organic polymer electrolyte gel with a solid content of 1%, and then add LLZO to mix and disperse to form the first composite gel with an inorganic ratio of 10%; PEO copolymer and LiClO 4 Dissolve in water according to the lithium-oxygen ratio of 1:40 to form an organic polymer electrolyte gel with a solid content of 1%, and then add lithium, lanthanum, zirconium, and oxygen to mix and disperse to form a second composite gel with an inorganic ratio of 5%;

[0051] Double-sidedly coat the first composite adhesive on the electrospinning separator, evaporate the solvent at 150°C, then apply the second composite adhesive on the first composite adhesive layer, and evaporate the solvent at 150°C to obtain a composite solid electrolyte membrane;

[0052] A solid-state lithium-ion battery is formed by using a composite solid electrolyte membrane with a lith...

Embodiment 3

[0058] Dissolve PEC and LiBOB in NMP at a lithium-to-oxygen ratio of 1:5 to form an organic polymer electrolyte gel with a solid content of 10%, and then add LATP to mix and disperse to form the first composite gel with an inorganic ratio of 30%; PEC and LiBOB are dissolved in water according to the lithium-oxygen ratio of 1:6 to form an organic polymer electrolyte gel with a solid content of 9%, and then add lithium, lanthanum, zirconium, and oxygen to mix and disperse to form a second composite gel with an inorganic ratio of 15%;

[0059] Double-sidedly coat the first composite adhesive on the non-woven fabric separator, evaporate the solvent at 150°C, then apply the second composite adhesive on the first composite adhesive layer, and evaporate the solvent at 130°C to obtain a composite solid electrolyte membrane;

[0060] A solid-state lithium-ion battery is made by using a composite solid electrolyte membrane with a ternary material positive electrode sheet and a lithium n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com