Palladium plating solution and palladium coating obtained using same

A technology of plating solution and palladium salt, which is applied in liquid chemical plating, metal material coating technology, coating, etc., can solve the problems of insufficient physical properties of the coating, and achieve the effects of cost reduction, cost reduction, and film thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

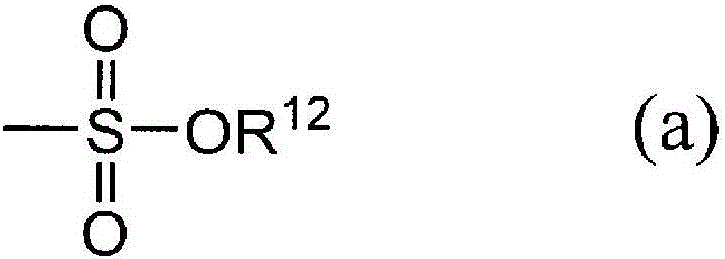

Method used

Image

Examples

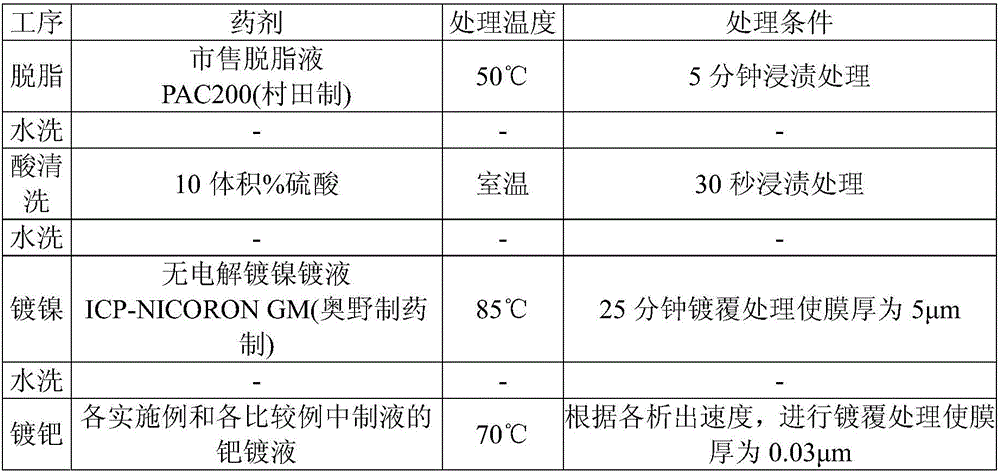

Embodiment 1~8、 comparative example 1~7

[0186]

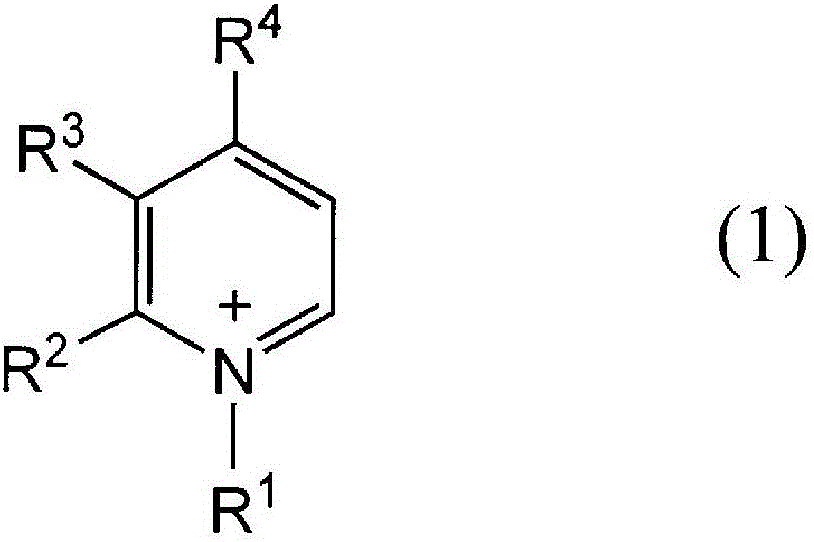

[0187] With respect to the whole palladium plating solution, the specific pyridinium compound or its comparative compound described in each embodiment and each comparative example shown in Table 1 is respectively 1000ppm, Formic acid as a reducing agent was dissolved at 1000 ppm and citric acid as a component of a conductivity salt and a buffer was dissolved at 100 g / L to adjust the pH to 6.5 to prepare an electroless palladium plating bath. However, Comparative Example 7 contained neither the specific pyridinium compound nor the comparative compound.

[0188] As "comparative compounds", pyridine, pyridine-3-sulfonic acid, picoline, quinolinesulfonic acid, 2,3-diaminopyridine, and 3-(3-pyridyl)acrylic acid were used.

[0189] In addition, as Comparative Example 7, a palladium plating solution prepared in the same manner that contained neither the "specific pyridinium compound" nor the "comparative compound" was evaluated.

[0190] The pH of the electroless palladiu...

Embodiment 11~18

[0220] The same evaluation samples as those used in Examples 1 to 8 were produced, and gold coatings of 0.01 μm, 0.05 μm, and 0.1 μm were respectively formed thereon.

[0221] A heat resistance test was conducted. As a result, any of Examples 11 to 18 contained less than 10% of nickel and less than 0.5% of copper in any thickness of the gold coating, so all were judged to be good products.

Embodiment 21

[0227]

[0228] With respect to the whole palladium plating solution, the specific pyridinium compound (1-methyl-3-carboxypyridinium hydrochloride) as in Example 1 was 1000ppm based on the dichlorotetraammine palladium solution as 1 g / L in terms of palladium. Dissolved with citric acid, which is a component serving as a conductivity salt and a buffer agent, at 100 g / L, adjusted the pH to 6.5, and prepared an electrolytic palladium plating solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com