Resist underlayer film forming composition containing novolac resin reacted with aromatic methylol compound

A novolak resin, aromatic compound technology, applied in the coating, the photoengraving process of the pattern surface, the photosensitive material used in the opto-mechanical equipment, etc., can solve the problems such as the decline of the resolution and the easy collapse of the resist pattern. , to achieve the effect of excellent spin coating, high dry etching resistance and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

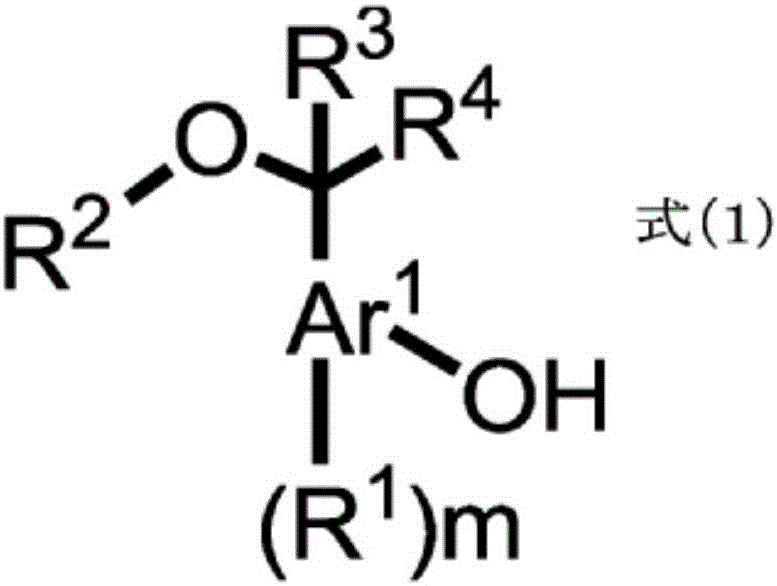

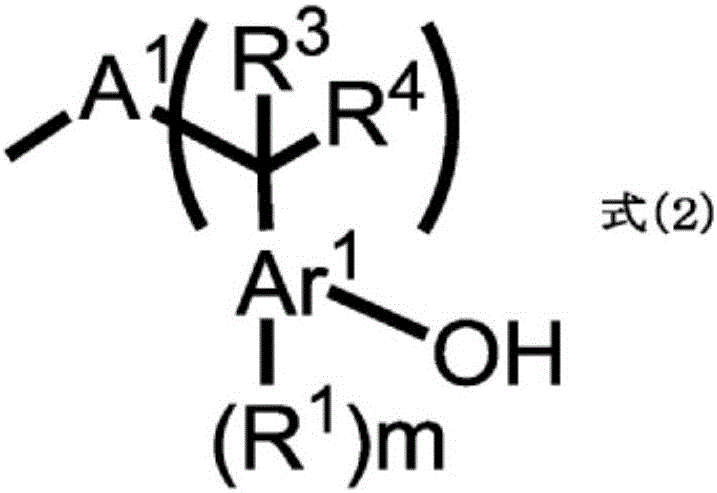

Method used

Image

Examples

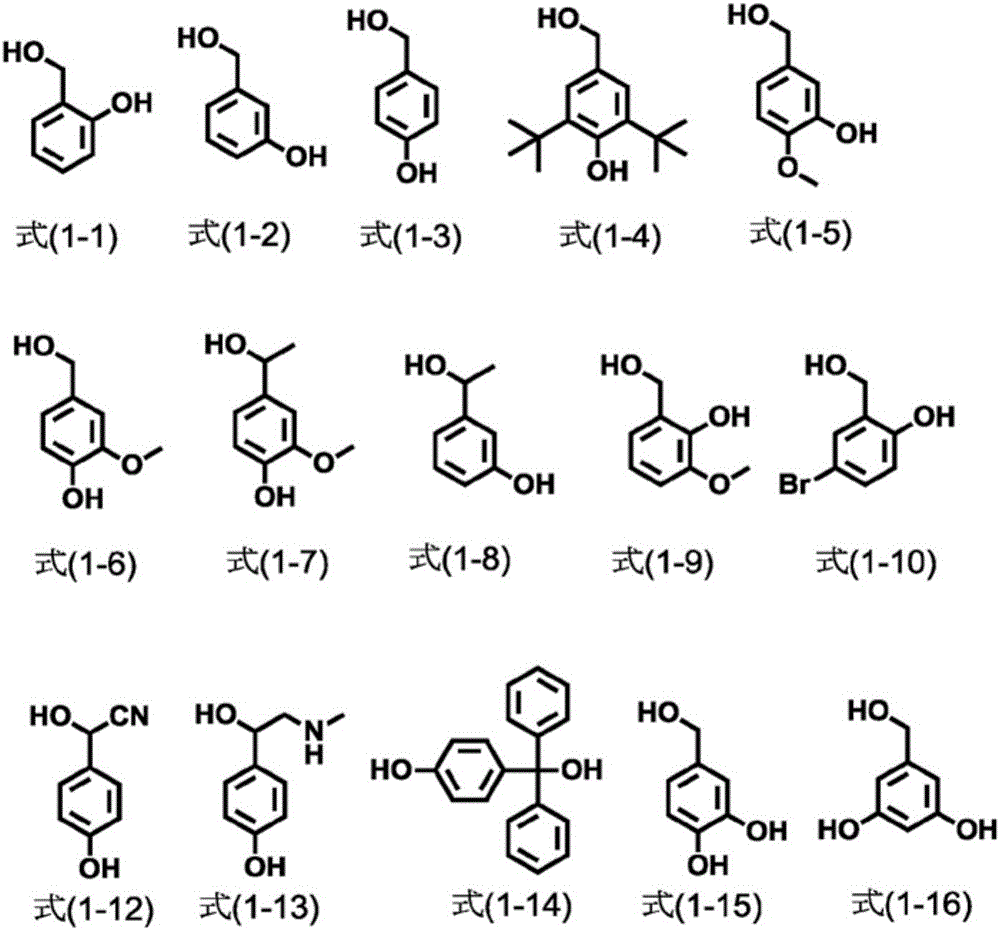

Embodiment 1

[0123] Add 29.96g propylene glycol monomethyl ether in the 2-phenylindole of 8.00g, the 1-pyrene formaldehyde of 5.72g, the 2-hydroxybenzyl alcohol of 2.06g, the methanesulfonic acid of 0.36g, under nitrogen atmosphere, in Stirring was performed at 130° C. for 24 hours. The reaction solution was added dropwise to methanol, and the precipitated resin was filtered, washed, and dried under reduced pressure at 70° C. to obtain 6.15 g of a resin containing the formula (3-1). In addition, the weight average molecular weight of this resin measured by GPC in terms of standard polystyrene was 1370.

[0124] Next, 1.00 g of the obtained resin and 0.002 g of a surfactant (manufactured by DIC Corporation, product name: Megaface [trade name] R-40, fluorine-based surfactant) were dissolved in 5.70 g of propylene glycol monomethyl ether, A composition for forming a resist underlayer film was prepared in 13.30 g of propylene glycol monomethyl ether acetate.

Embodiment 2

[0126] Add 29.96g propylene glycol monomethyl ether in the 2-phenylindole of 8.00g, the 1-pyrene formaldehyde of 5.72g, the 4-hydroxybenzyl alcohol of 2.06g, the methanesulfonic acid of 0.36g, under nitrogen atmosphere, in Stirring was performed at 130° C. for 24 hours. The reaction solution was added dropwise to methanol, and the precipitated resin was filtered, washed, and then dried under reduced pressure at 70° C. to obtain 5.52 g of a resin containing formula (3-2). In addition, the weight average molecular weight of this resin measured by GPC in terms of standard polystyrene was 1100.

[0127] Next, 1.00 g of the obtained resin and 0.002 g of a surfactant (manufactured by DIC Corporation, product name: Megaface [trade name] R-40, fluorine-based surfactant) were dissolved in 5.70 g of propylene glycol monomethyl ether, A composition for forming a resist underlayer film was prepared in 13.30 g of propylene glycol monomethyl ether acetate.

Embodiment 3

[0129] Add 31.32 g of propylene glycol monosodium to 7.50 g of 2-phenylindole, 5.36 g of 1-pyrene formaldehyde, 3.70 g of 2,6-di-tert-butyl-4-hydroxymethylphenol, and 0.34 g of methanesulfonic acid. Methyl ether was stirred at 130° C. for 24 hours under a nitrogen atmosphere. The reaction solution was added dropwise to methanol, and the precipitated resin was filtered, washed, and then dried under reduced pressure at 70° C. to obtain 6.45 g of a resin containing formula (3-3). In addition, the weight average molecular weight of this resin measured by GPC in terms of standard polystyrene was 1510.

[0130] Next, 1.00 g of the obtained resin and 0.002 g of a surfactant (manufactured by DIC Corporation, product name: Megaface [trade name] R-40, fluorine-based surfactant) were dissolved in 5.70 g of propylene glycol monomethyl ether, A composition for forming a resist underlayer film was prepared in 13.30 g of propylene glycol monomethyl ether acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com