Strain composition suitable for fermenting needle mushroom residues and brewer's grains, and application thereof

A technology of Flammulina velutipes residue and composition, which is applied in the field of fermentation and achieves the effects of reducing the content of acidic fiber, good palatability and increasing the content of fenugreek

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

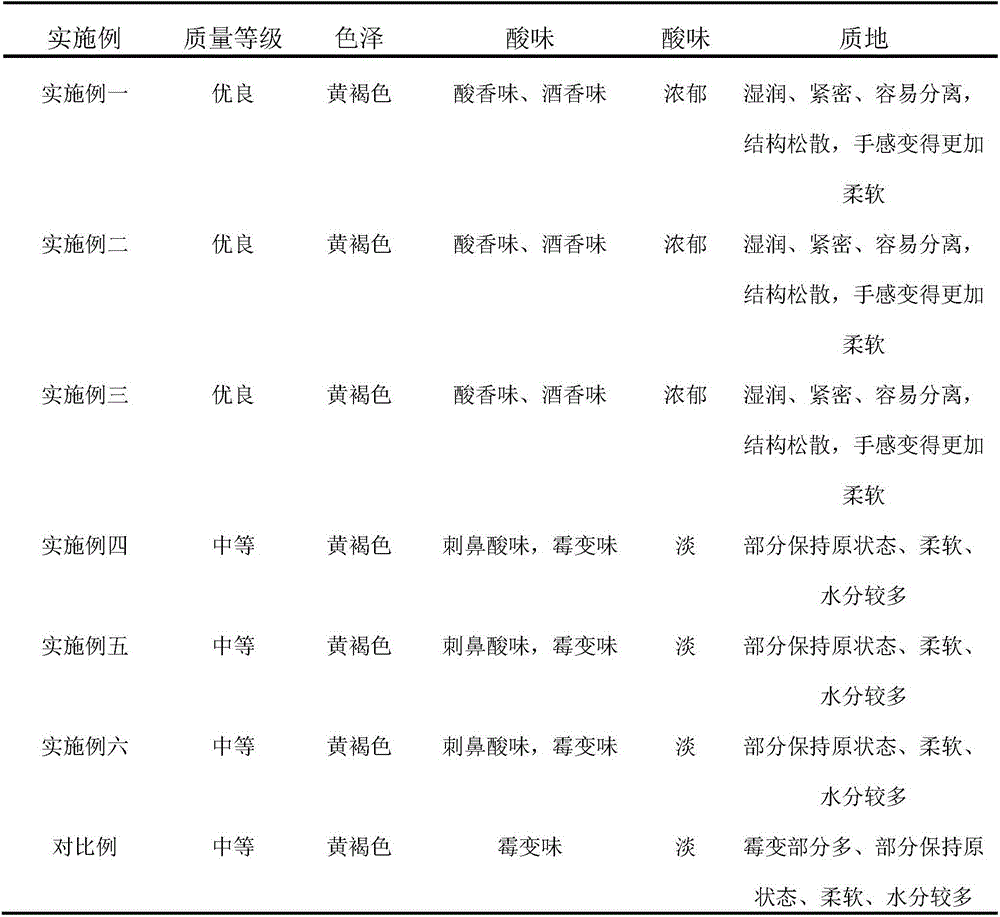

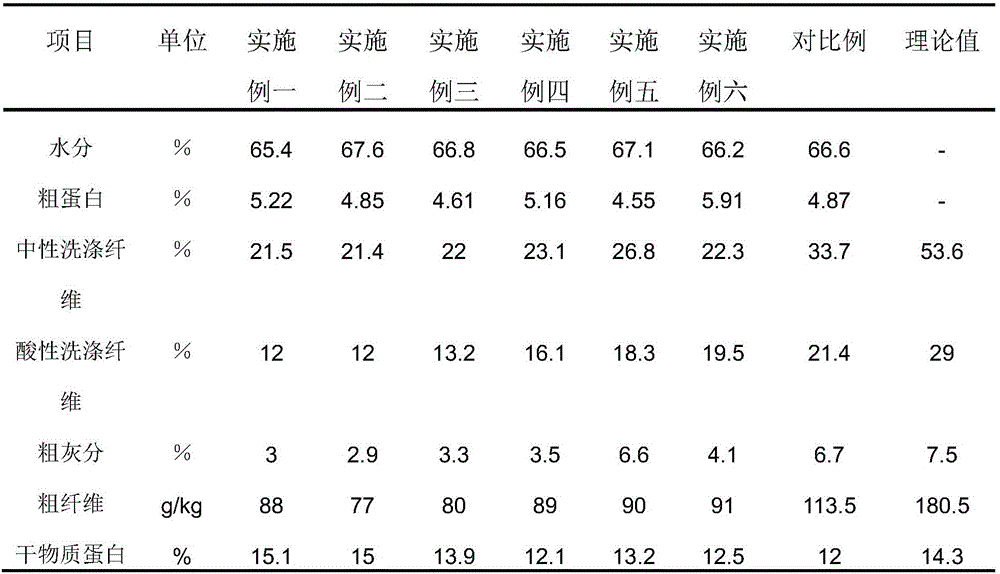

Embodiment 1

[0028] The fermented strain compositions provided in this embodiment one are: Lactobacillus plantarum ST-Ⅲ (Lactobacillusplantarum CGMCC 0847), Paenibacillus (P.bovis CGMCC 8333) and Paenibacillus polymyxa (P.polymyxa CGMCC 10062), Activate them separately, and mix them at a ratio of 1:1:1 after expanding the culture to obtain a prefabricated composite bacterial suspension. The prefabricated composite bacteria suspension is diluted with sterile water to obtain the composite bacteria suspension. Flammulina velutipes residue and brewer's grains are used as fermentation substrates, and the weight ratio is 1:2. The composite bacteria suspension is inoculated to the fermentation substrate, and the inoculation amount is 2% of the total volume of the fermentation substrate. Ferment at 30°C for 3-7 days to obtain a fermentation complex.

Embodiment 2

[0030] The fermented strain composition in this example is Lactobacillus plantarum ST-Ⅲ (Lactobacillus plantarumCGMCC 0847) and Paenibacillus (P.bovis CGMCC 8333), which are respectively activated, and mixed at a ratio of 1:1 after expanded cultivation to obtain prefabricated composite bacteria Suspension. The prefabricated composite bacteria suspension is diluted with sterile water to obtain the composite bacteria suspension. Flammulina velutipes residue and brewer's grains are used as fermentation substrates, and the weight ratio is 1:2. The composite bacteria suspension is inoculated to the fermentation substrate, and the inoculation amount is 2% of the total volume of the fermentation substrate. Ferment at 30°C for 3-7 days to obtain a fermentation complex.

Embodiment 3

[0032] The fermentation strain composition in this example is Lactobacillus plantarum ST-Ⅲ (Lactobacillus plantarumCGMCC 0847) and Paenibacillus polymyxa (P.polymyxa CGMCC 10062), which are respectively activated and mixed at a ratio of 1:1 after expanded cultivation to obtain prefabricated Composite bacterial suspension. The prefabricated composite bacteria suspension is diluted with sterile water to obtain the composite bacteria suspension. Flammulina velutipes residue and brewer's grains are used as fermentation substrates, and the weight ratio is 1:2. The composite bacteria suspension is inoculated to the fermentation substrate, and the inoculation amount is 2% of the total volume of the fermentation substrate. Ferment at 30°C for 3-7 days to obtain a fermentation complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com