Implanted flexible neural microelectrode comb, and preparation method and implanting method thereof

A micro-electrode, implantable technology, applied in the field of neurobiomaterials and microelectronics science, can solve the problems of difficult implantation inside the brain, insufficient rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0117] The specific embodiment of the present invention provides a preparation method of the implantable flexible nerve microelectrode comb, such as Figure 4 As shown, the preparation method includes the following steps:

[0118] (1) Spin-coating positive photoresist on the carrier, pre-baking, photoetching the marking pattern, leaving the pad position with photoresist for protection, post-baking the film to remove the residual glue;

[0119] (2) Vapor-deposit or sputter a sacrificial layer on the carrier obtained after step (1), and peel off to form the sacrificial layer and marking patterns;

[0120] (3) In step (2), the side of the carrier where the aluminum sacrificial layer and the marking pattern are formed is spin-coated with a flexible substrate material, followed by pre-baking, exposure, post-baking, and developing treatments to form a flexible substrate layer. Hard film

[0121] (4) Spin-coating positive photoresist on the flexible substrate layer formed in step (3), and fo...

Embodiment 1

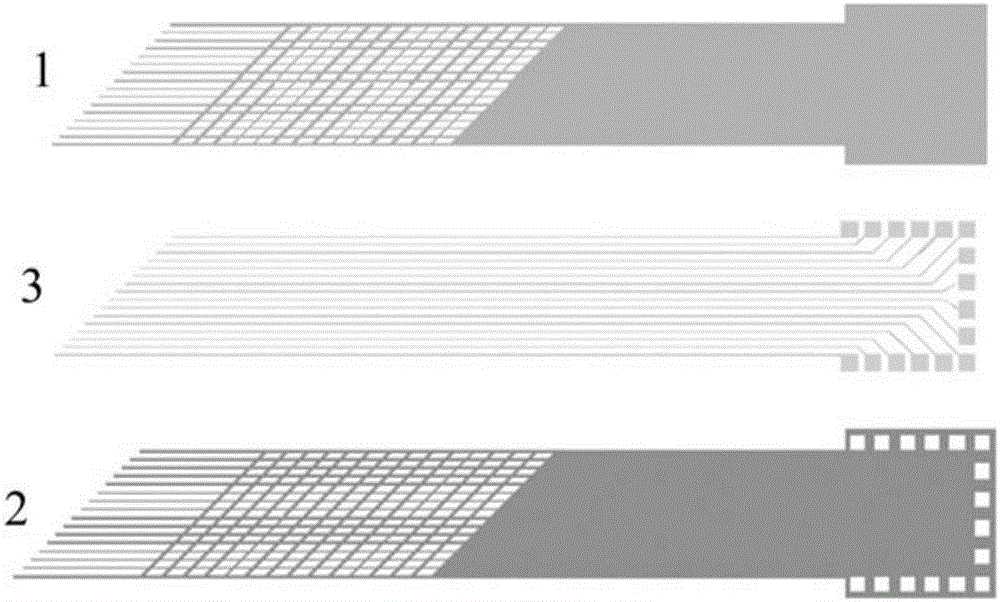

[0133] This embodiment provides an implantable flexible nerve microelectrode comb. The flexible nerve microelectrode comb is mainly composed of a flexible substrate layer 1, a flexible insulating layer 2, and a metal Au disposed between the flexible substrate layer 1 and the flexible insulating layer 2. The connecting wire layer 3 is composed of the flexible substrate layer 1 and the flexible insulating layer 2 are made of SU-8 photoresist, the thickness of the flexible substrate layer 1 and the flexible insulating layer 2 are both 5 μm, and the metal Au connecting wire layer 3 The thickness is 100nm.

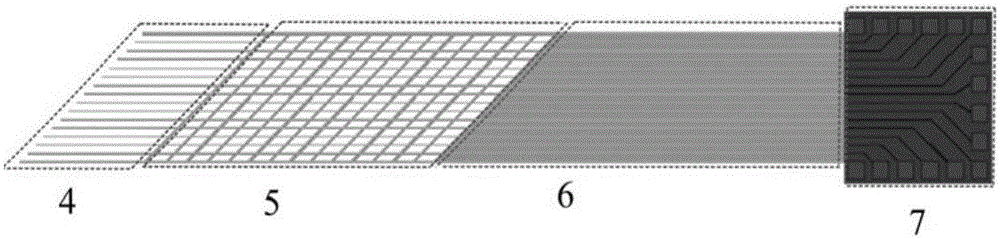

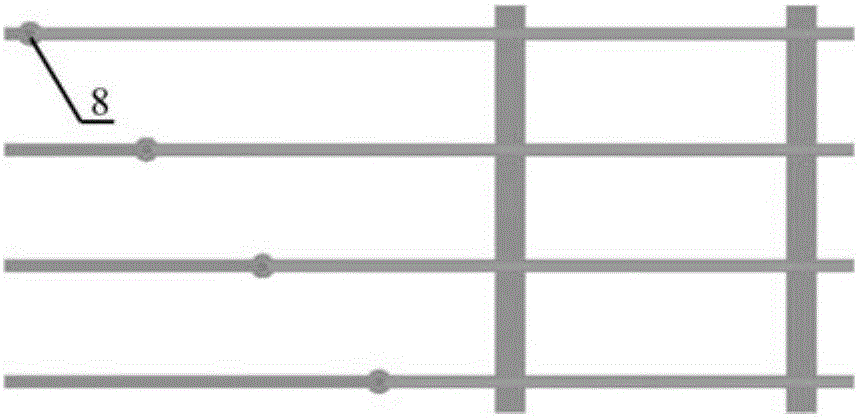

[0134] The flexible nerve microelectrode comb includes a comb-tooth structure 4, a grid structure 5, a solid structure 6 and a pad 7 which are sequentially connected; the comb-tooth structure 4 is provided with electrode sites 8; and the pad 7 There are welding points on it.

[0135] The metal Au connecting wire layer 3 is composed of a metal Au connecting wire, the line width of t...

Embodiment 2

[0143] This embodiment provides a flexible nerve microelectrode comb, the flexible nerve microelectrode comb is mainly composed of a flexible substrate layer 1, a flexible insulating layer 2, and a metal platinum connecting wire arranged between the flexible substrate layer 1 and the flexible insulating layer 2. The layer 3 consists of the flexible substrate layer 1 and the flexible insulating layer 2 using SU-8, the thickness of the flexible substrate layer 1 and the flexible insulating layer 2 are both 5 μm, and the thickness of the metal platinum connecting wire layer 3 is 100 nm.

[0144] The flexible nerve microelectrode comb includes a comb-tooth structure 4, a grid structure 5, a solid structure 6 and a pad 7 which are sequentially connected; the comb-tooth structure 4 is provided with electrode sites 8; and the pad 7 There are welding points on it.

[0145] The metallic platinum connecting wire layer 3 is composed of metallic platinum connecting wires, the line width of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com