A kind of SIO2 modified low-carbon alkane dehydrogenation catalyst and preparation method thereof

A technology for dehydrogenation catalysts and low-carbon alkanes, which is applied in the direction of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problems of blocking secondary pores and changing the internal structure of pores, and achieves the improvement of mechanical strength and the selection of olefins. The effect of good resistance, high mechanical strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

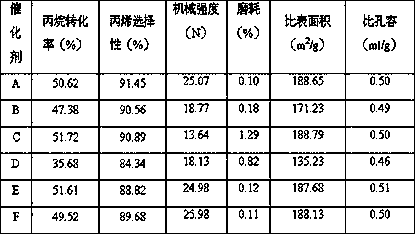

Examples

Embodiment 1

[0033] (1) Select chromium nitrate as the active component precursor, weigh an appropriate amount of chromium nitrate and make it into an aqueous solution, impregnate 10kg of active Al 2 o 3 carrier, the immersion time is 5h. Then place it in a drying oven for drying, the drying temperature is 110° C., and the drying time is 6 hours. Then it is placed in a muffle furnace for calcination, the calcination temperature is 600°C, and the calcination time is 6h.

[0034] (2) Measure the mass water absorption rate of the catalyst obtained after roasting to 68%, prepare an aqueous solution with appropriate amount of copper nitrate and potassium nitrate with 7.11kg of ionized water, impregnate the catalyst obtained in step (1) to make it absorb water to saturation.

[0035] (3) Evenly spread the catalyst that has absorbed water to saturation on the drying belt with a thickness of 3.5cm. Control the transmission speed of the drying belt to 50m / h, the drying temperature to 150°C, and p...

Embodiment 2

[0048] (1) Select chromium acetate as the active component precursor, weigh an appropriate amount of chromium acetate and make it into an aqueous solution, impregnate 10kg of active Al 2 o 3 carrier, the immersion time is 6h. Then place it in a drying oven for drying, the drying temperature is 120° C., and the drying time is 5 hours. Then it is placed in a muffle furnace for calcination, the calcination temperature is 700°C, and the calcination time is 5h.

[0049] (2) Measure the mass water absorption rate of the catalyst obtained after roasting to 65%, and prepare an aqueous solution with an appropriate amount of cerium nitrate and ferric nitrate with 7.06 kg of ionized water, and impregnate the catalyst obtained in step (1) to make it absorb water to saturation.

[0050] (3) Spread the catalyst that has absorbed water to saturation evenly on the drying belt with a thickness of 4cm. Control the transmission speed of the drying belt to 45m / h, the drying temperature to 140°C...

Embodiment 3

[0055] (1) Select chromic acid as the precursor of the active component, weigh an appropriate amount of chromic acid and make it into an aqueous solution, impregnate 10kg of active Al 2 o 3 carrier, the immersion time is 6h. Then place it in a drying oven for drying, the drying temperature is 110° C., and the drying time is 5 hours. Then place it in a muffle furnace for calcination, the calcination temperature is 650°C, and the calcination time is 5h.

[0056] (2) Measure the mass water absorption rate of the catalyst obtained after roasting to 66%, prepare an aqueous solution with appropriate amounts of gallium nitrate and zinc nitrate with 7.49kg of ionized water, and impregnate the catalyst obtained in step (1) to make it absorb water to saturation.

[0057] (3) Spread the catalyst that has absorbed water to saturation evenly on the drying belt with a thickness of 4cm. Control the transmission speed of the drying belt to 45m / h, the drying temperature to 140°C, and pass th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com