A kind of giant dielectric low-loss CCTO-based ceramic material and preparation method thereof

A technology of ceramic materials and giant dielectric constant, which is applied in the field of CaCu3Ti4O12-based ceramic materials and its preparation, can solve the problems of damaging the dielectric constant characteristics of CCTO ceramics, low material dielectric constant, and increased dielectric loss, and achieve less pores , Narrow particle size distribution and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The present invention will be further described below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0016] The selected raw materials of the present invention can be purchased through commercial channels unless otherwise specified.

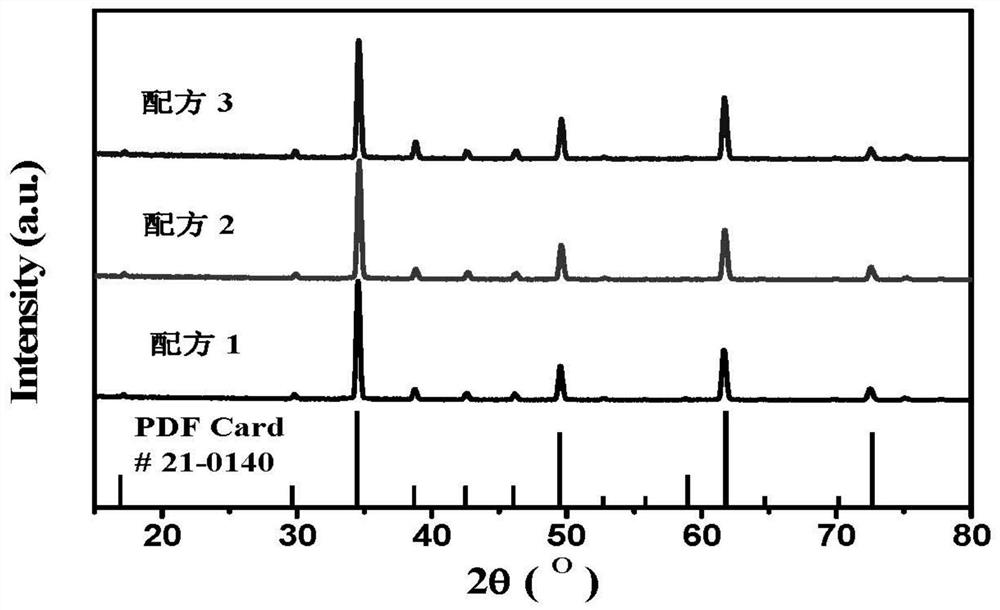

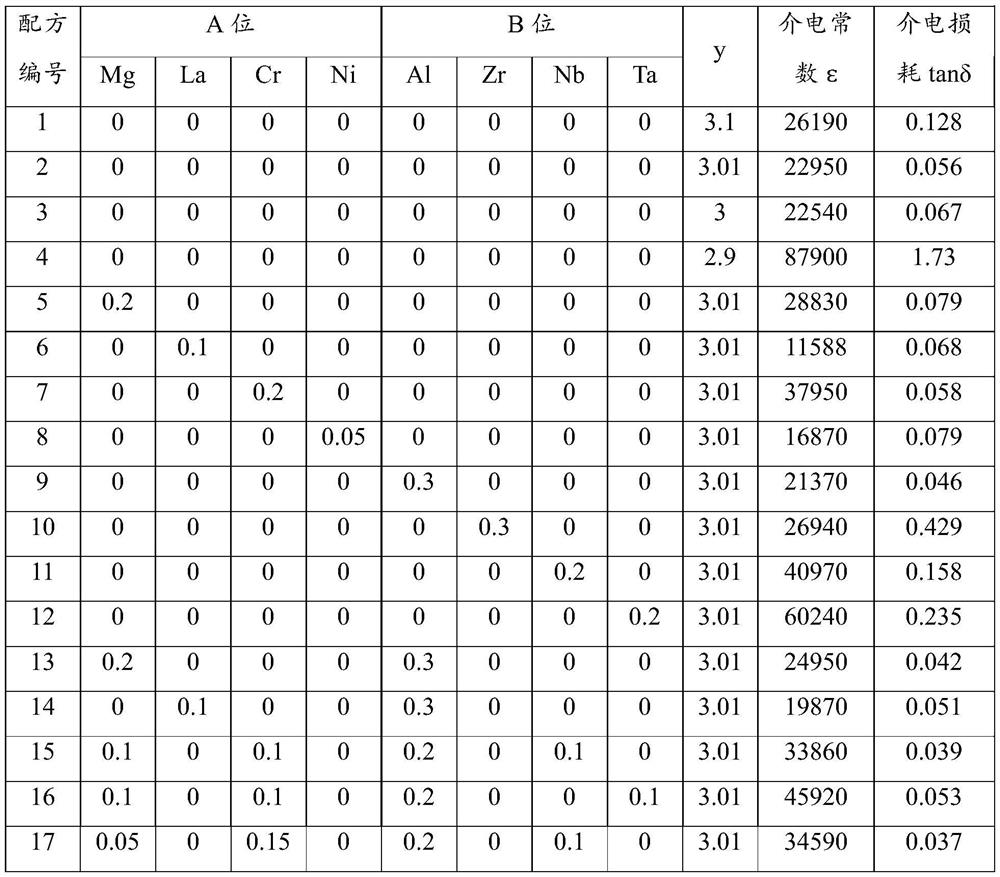

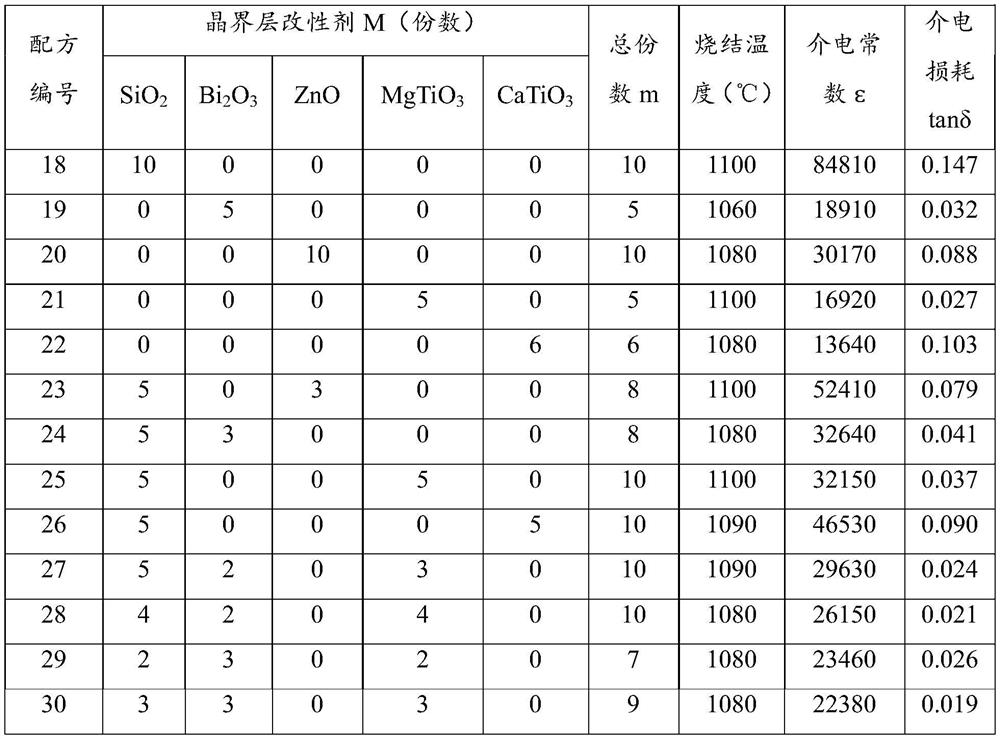

[0017] Main ingredient Ca 1-x A x Cu y Ti 4-z B z o 12 The preparation method of ceramic powder: the formula is as shown in table 1, with analytically pure CaCO 3 , CuO, TiO 2 , MgO, La 2 o 3 、Cr 2 o 3 、Ni 2 o 3 、Al 2 o 3 , ZrO 2 , Nb 2 o 5 、 Ta 2 o 5 According to the stoichiometric ratio of the main material Ca 1- x A x Cu y Ti 4-z B z o 12 (A is a combination of one or more of Mg, La, Cr, Ni, B is a combination of one or more of Al, Zr, Nb, Ta, 0figure 1 The XRD patterns of the main ingredients of formulas 1 to 3 are completely consistent with the standard spectra, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com