Separation and purification method of atisine chloride atractydin monomers

A technology for separation and purification of atractylodes, which is applied in the field of separation and purification of atractylodes monomers. It can solve the problems such as the separation process of high-purity atractylodes monomers, and achieve the effects of easy cost control, good solubility and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

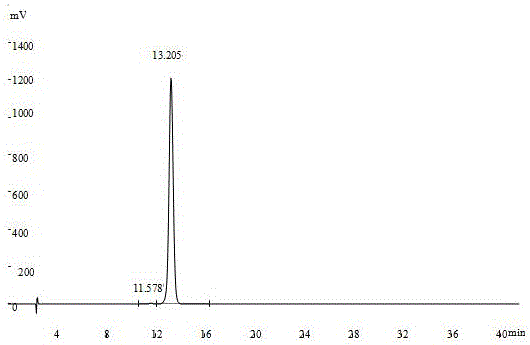

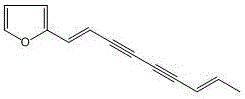

Image

Examples

Embodiment 1

[0032] A method for separation and purification of atractylodes monomer, comprising the following process steps:

[0033] A. Raw material extraction

[0034] Crush 1 kg of Atractylodes atractylodis into particles with a diameter of about 3mm, add 5L of ethanol solution with a volume percentage of 95%, extract twice at 50°C for 2 hours each time, filter, collect, and combine the filtrates, concentrate to no alcohol, and the volume is about 300mL.

[0035] B. Extraction

[0036] The concentrated solution of step A was extracted three times with ethyl acetate at a volume ratio of 1:1, and the ethyl acetate was partially concentrated to a small volume.

[0037] C. Sample mixing and drying

[0038] Add about 50 grams of silica gel (60-80 mesh) to the ethyl acetate part to mix the sample, and dry it with air at 50°C to obtain 67 grams of dried mixed sample silica gel.

[0039] D. Silica gel column chromatography

[0040] Put the mixed sample into the packed silica gel (200-300 ...

Embodiment 2

[0047] A method for separation and purification of atractylodes monomer, comprising the following process steps:

[0048] A. Raw material extraction

[0049] Crush 5 kg of Atractylodes atractylodis into particles with a diameter of about 3mm, add 30L of ethanol solution with a volume percentage of 95%, extract twice at 50°C for 2 hours each time, filter, collect, and combine the filtrates, concentrate until alcohol-free, volume About 1.5L.

[0050] B. Extraction

[0051] The concentrated solution of step A was extracted three times with ethyl acetate at a volume ratio of 1:1, and the ethyl acetate was partially concentrated to a small volume.

[0052] C. Sample mixing and drying

[0053] Add about 280 grams of silica gel (60-80 mesh) to the ethyl acetate part to mix the sample, and dry it with air at 50°C to obtain 350 grams of dried mixed sample silica gel.

[0054] D. Silica gel column chromatography

[0055] Put the mixed sample into the packed silica gel (200-300 mesh...

Embodiment 3

[0061] A method for separation and purification of atractylodes monomer, comprising the following process steps:

[0062] A. Raw material extraction

[0063] Crush 25 kg of Atractylodes atractylodis into particles with a diameter of about 3 mm, add 125 L of ethanol solution with a volume percentage of 95%, extract 3 times at 50 ° C, each time for 2 hours, filter, collect, and combine the filtrates, concentrate to no alcohol, volume About 10L.

[0064] B. Extraction

[0065] The concentrated solution of step A was extracted three times with ethyl acetate at a volume ratio of 1:1, and the ethyl acetate was partially concentrated to a small volume.

[0066] C. Sample mixing and drying

[0067] Add about 1.3 kg of silica gel (60-80 mesh) to the ethyl acetate portion to mix the sample, and dry it with air at 50°C to obtain 1.7 kg of dried mixed sample silica gel.

[0068] D. Silica gel column chromatography

[0069] Put the mixed sample into the packed silica gel (200-300 mesh, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com