Method for refining tadalafil

A tadalafil and quality technology, applied in the field of refining tadalafil, can solve problems such as reducing the utilization rate of crude products, achieve significant economic value and environmental protection value, improve yield, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

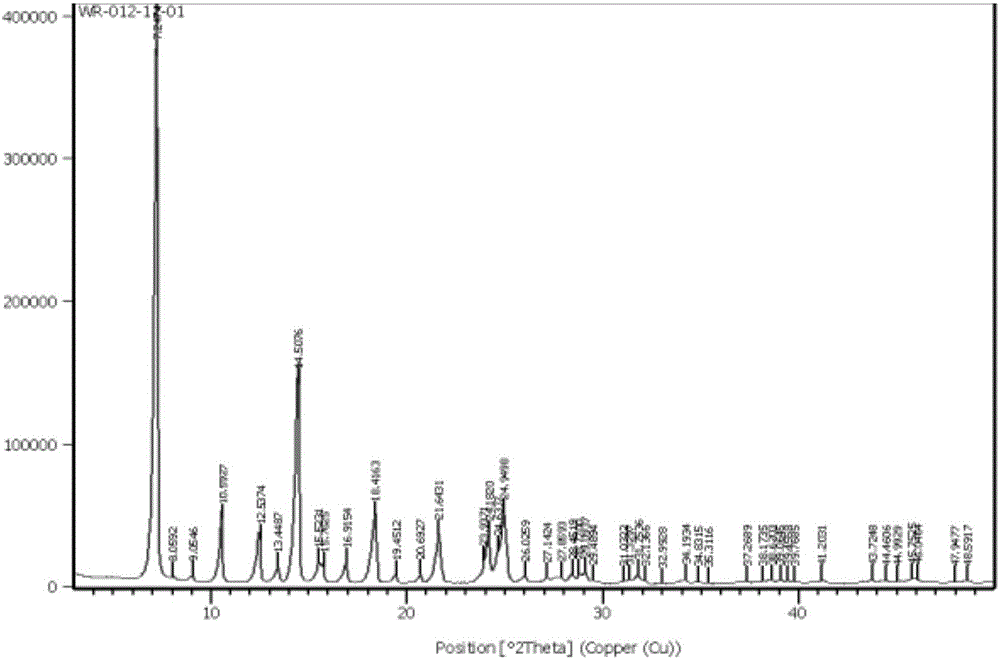

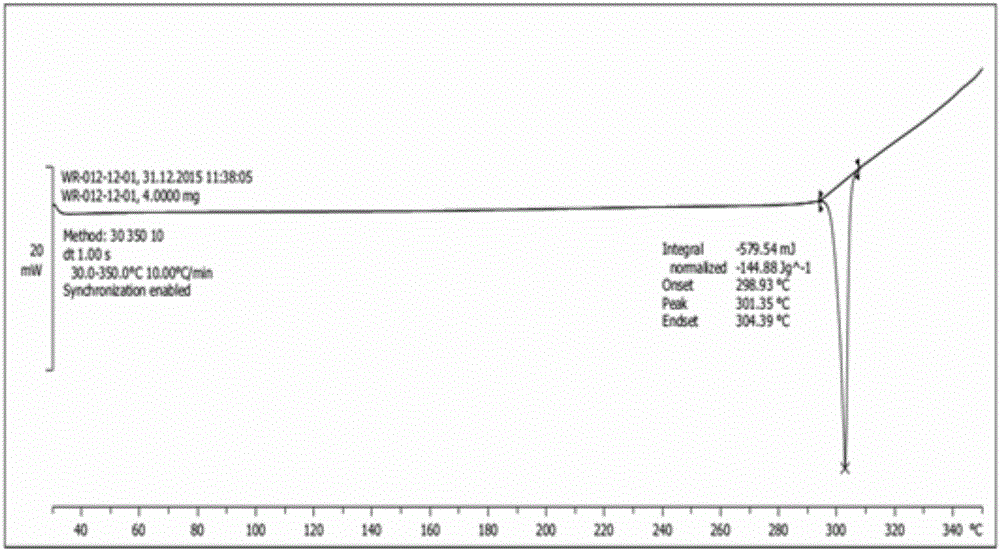

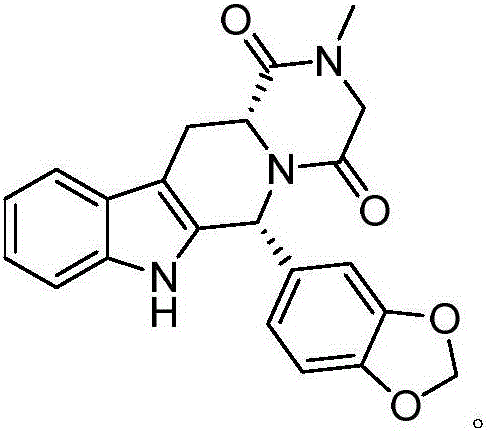

Image

Examples

Embodiment 1

[0027] Reference Example 1: Preparation of Tadalafil Crude Product

[0028] Referring to patent WO2004011463, crude tadalafil was prepared, with purity (HPLC): 99.42%, impurity A (HPLC): 0.26%, other maximum single impurities (HPLC): 0.17%.

[0029] Example 1

[0030] At room temperature, take 5.5 g of the crude product of tadalafil prepared in Reference Example 1 and add it into a 500 mL four-necked bottle. Then add 100.0 g of methanol and 100.0 g of acetic acid, and start stirring. Raise the temperature to 80-85°C, heat the material and stir for 1-2 hours after the material is dissolved. After distilling off 133g of the mixed solvent, crystals gradually precipitated. Slowly lower the temperature to 0°C and continue crystallization for 1-2 hours, filter, wash with about 5g of methanol, and dry in vacuum at 50°C for 8 hours to obtain 5.09g of tadalamorph A, yield 92.5%, purity (HPLC): 99.86 %, impurity A (HPLC): 0.05%, other maximum single impurity (HPLC): 0.07%.

Embodiment 2

[0032] At room temperature, take 10.0 g of the crude product of tadalafil prepared in Reference Example 1 and add it into a 500 mL four-necked bottle. Add 50.0 g of methanol and 150.0 g of acetic acid, and start stirring. Raise the temperature to 80-85°C, heat the material and stir for 1-2 hours after the material is dissolved. After distilling off 133g of the mixed solvent, crystals gradually precipitated. Slowly lower the temperature to 0°C and continue crystallization for 1-2 hours, filter, wash with about 5g of methanol, and dry in vacuum at 50°C for 8 hours to obtain 9.29g of tadalamorph A, yield 92.9%, purity (HPLC): 99.88 %, impurity A (HPLC): 0.04%, other maximum single impurity (HPLC): 0.07%.

Embodiment 3

[0034] At room temperature, take 15.0 g of the crude tadalafil product prepared in Reference Example 1 and add it into a 500 mL four-necked bottle. Add 20.0 g of methanol and 180.0 g of acetic acid, and start stirring. Raise the temperature to 80-85°C, heat the material and stir for 1-2 hours after the material is dissolved. After distilling off 133g of the mixed solvent, crystals gradually precipitated. Slowly lower the temperature to 0°C and continue crystallization for 1-2 hours, filter, wash with about 5g of methanol, and dry in vacuum at 50°C for 8 hours to obtain 14.04g of tadalamorph A, yield 93.6%, purity (HPLC): 99.99 %, impurity A (HPLC): N.D, other maximum single impurity (HPLC): 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com