Liquid-stage pipeline drainage agent and preparation method thereof

A technology of liquid pipeline and dredging agent, applied in the field of daily chemical products, can solve the problems of accelerating the decomposition of oxygen bleaching agent, overheating and inactivation of pipelines, etc., achieving good hard water resistance, reducing contact distance, and cleaning and maintaining the effect of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

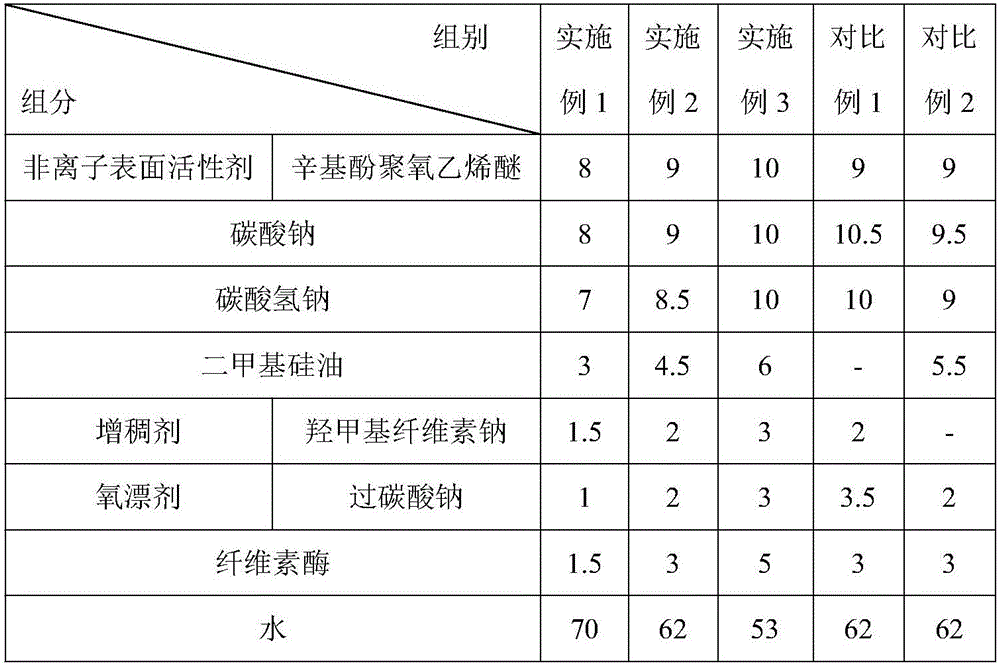

[0020] Embodiment 1-3, comparative example 1-2

[0021] Table 1 lists the components and mass percentages of the liquid pipe dredging agents of Examples 1-3 of the present invention and Comparative Examples 1-2.

[0022] Component and mass percent of table 1 embodiment and comparative example solid pipe dredging agent

[0023]

Embodiment 2

[0026] Embodiment 2 The preparation method of the liquid pipeline dredging agent: add 50% water in the batching system, add nonionic surfactant, sodium carbonate and sodium bicarbonate to the water and stir evenly; add simethicone under stirring; then add Thickener, stir evenly; add oxygen bleaching agent, cellulase and the remaining water, stir well, pack after passing the inspection.

Embodiment 1

[0027] Example 1, Example 3 and Comparative Example 1-2 The preparation method of the liquid pipe dredging agent is similar to that of Example 2.

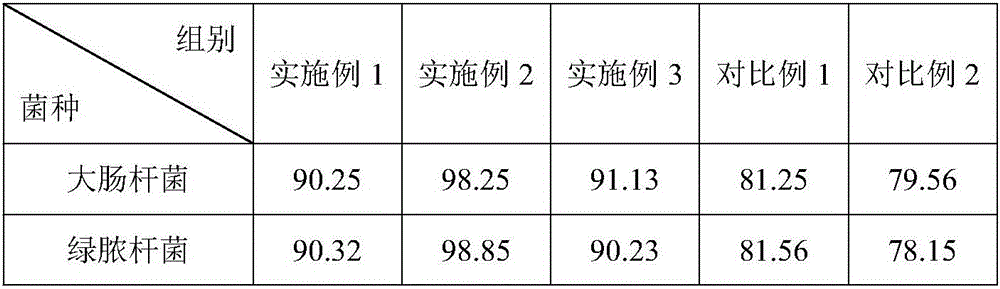

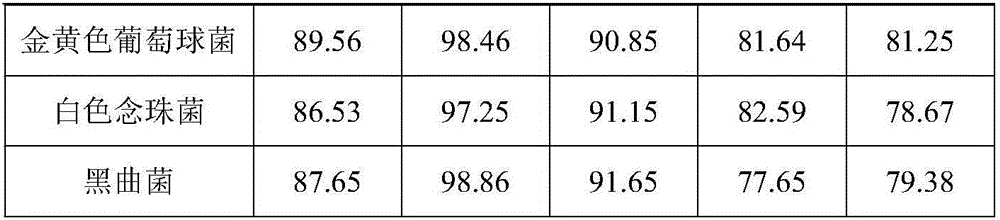

[0028] Product performance evaluation test

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com