Preparation method of proline endonuclease

An endoproline, proline technology, applied in biochemical equipment and methods, enzymes, peptidases and other directions, can solve the problem of no detection of proline endoprotease activity, unfavorable promotion and production, complex processes, etc. problems, to achieve the effect of wide temperature and pH adaptation range, easy control and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 The shake flask high-density fermentation of Aspergillus niger

[0022] Step 1: Streak the Aspergillus niger glycerin strains stored in conventional glycerol at -80°C on the wort medium plate, place it in a 30°C incubator and cultivate it for 2 days until a single colony grows; then pick a full single colony and streak Line inoculated on the wort medium plate, placed in 28°C incubator for 2 days, then took the full strain into 50mL BMGY liquid medium, 28°C, 200rpm shake flask cultured for 18h, to obtain the seed solution.

[0023] The composition of the BMGY liquid medium by weight percentage is: tryptone 20g / L, yeast extract 10g / L, 121°C, after sterilizing for 20min, adding 100mmol / L potassium phosphate at pH 6, 13.4g / L of amino nitrogen source, Biotin 4 x 10 -4 g / L (sterilized by filtration), glycerin 10g / L.

[0024] Step 2: In the aseptic environment of the ultra-clean workbench, under the protection of the flame, centrifuge the prepared seed solution ...

Embodiment 2

[0026] Embodiment 2 High-density fermentation in fermenter of Aspergillus niger

[0027] Step 1: with embodiment 1;

[0028] Step 2: In the aseptic operation room, insert the prepared seed solution into the Aspergillus niger high-density fermentation medium (same as Example 1), adjust the pH of the fermentation medium to 5.8, and cultivate at 30°C at 200-800r / min Fermentation; adjust the flow rate of 0.5 mg / L proline according to the pH and dissolved oxygen state of the fermenter, maintain the pH at 5.0-7.0, and maintain the dissolved oxygen at 35-50%, until the proline endonuclease enzyme The activity is slowly increased or no longer increased, and the fermentation is terminated. The fermentation time is 96-200h, and the fermentation bacteria concentration is 100-300g / L (calculated by the wet weight of the bacteria).

Embodiment 3

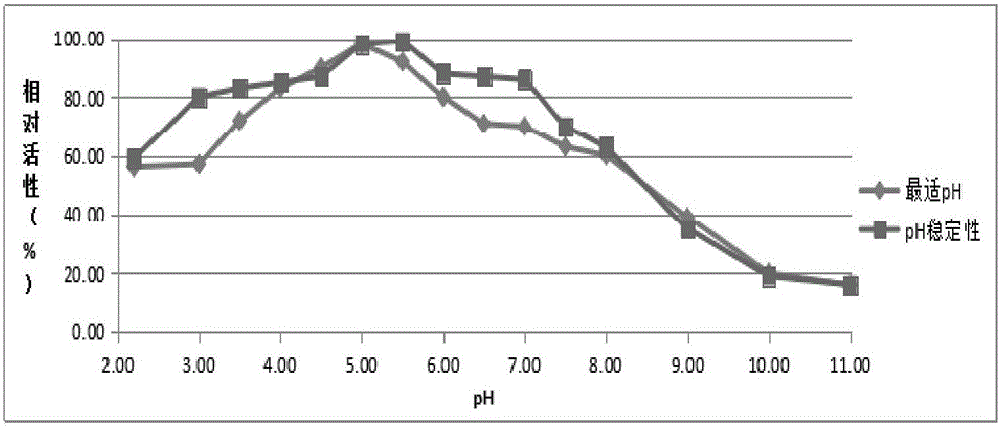

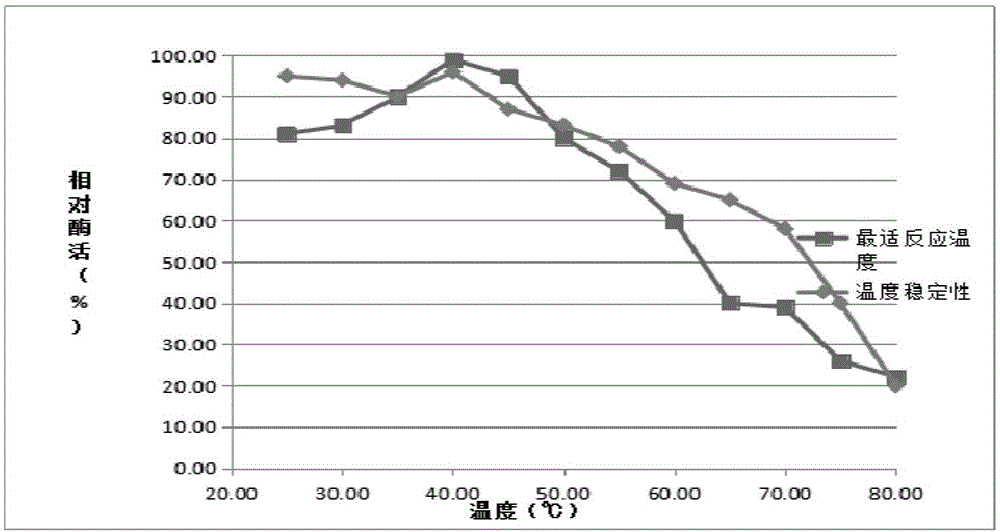

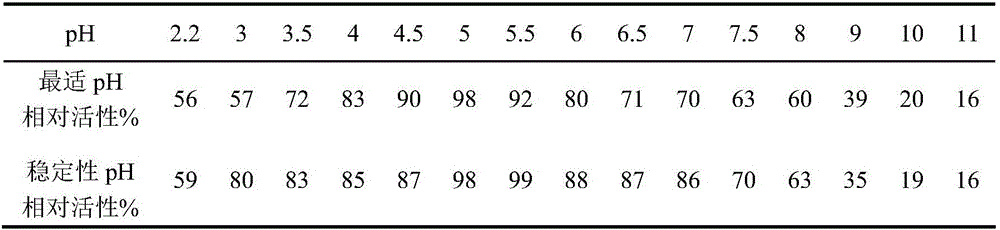

[0029] The optimal pH and stability of embodiment 3 proline endonuclease

[0030] Using proline as a substrate, determine the optimum pH and stability of proline endonuclease. Under the various pH conditions shown in Table 1, the relative activity was recorded after incubation at 37°C for 30 minutes, and the figure 1 pH curve shown. According to this curve, it can be seen that the enzyme shows the highest activity at pH 5.0, and the relative activity exceeds 60% between pH 3.5-8.0. It can be determined that its optimum pH range is 3.5-8.0. The optimum pH of Dicer is 4.5-5.5, and the method of the present invention obviously expands the optimum pH range of proline endonuclease. At the same time, from the perspective of the pH stability of the enzyme, it retains more than 80% of its initial activity between pH 3.0-7.0.

[0031] Table 1

[0032]

[0033] From the above data, it can be known that the proline endonuclease of the present invention can maintain stability in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com