Metal etching device and method

An etching device and metal technology, which is used in the manufacture/processing of electromagnetic devices to achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

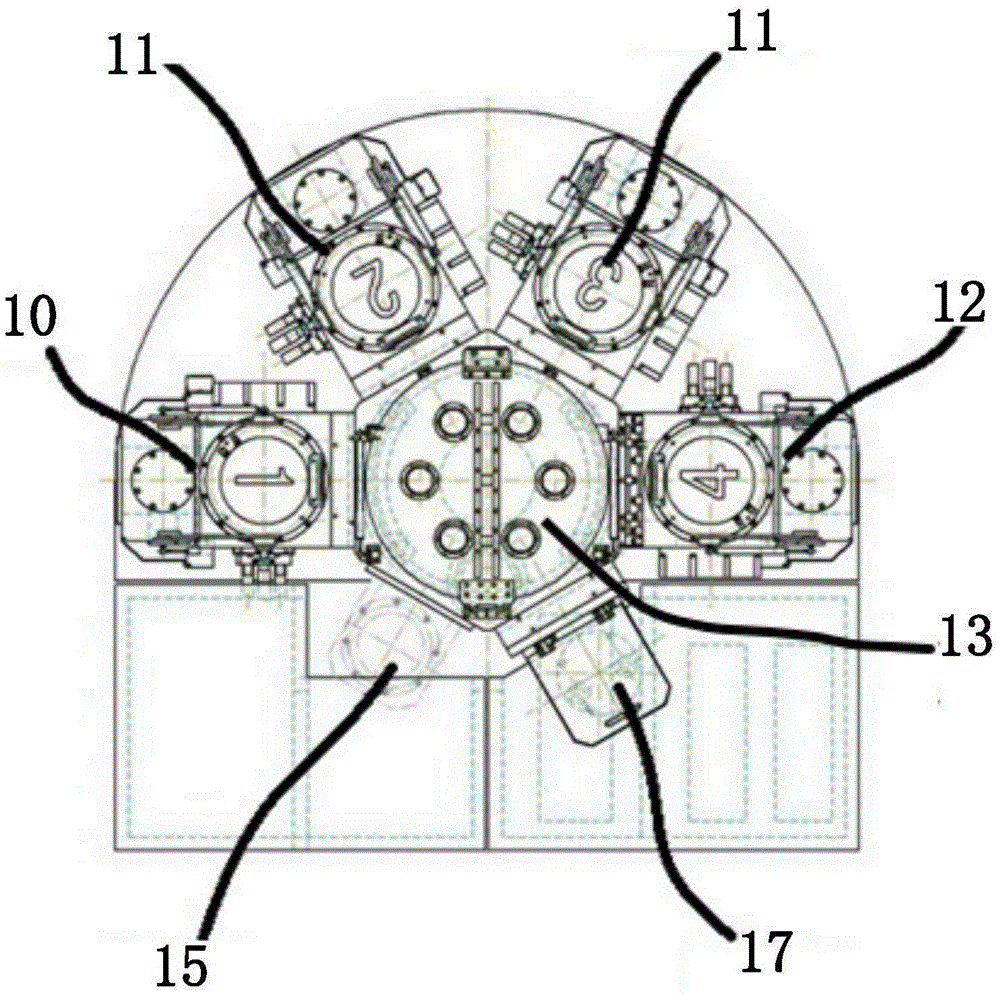

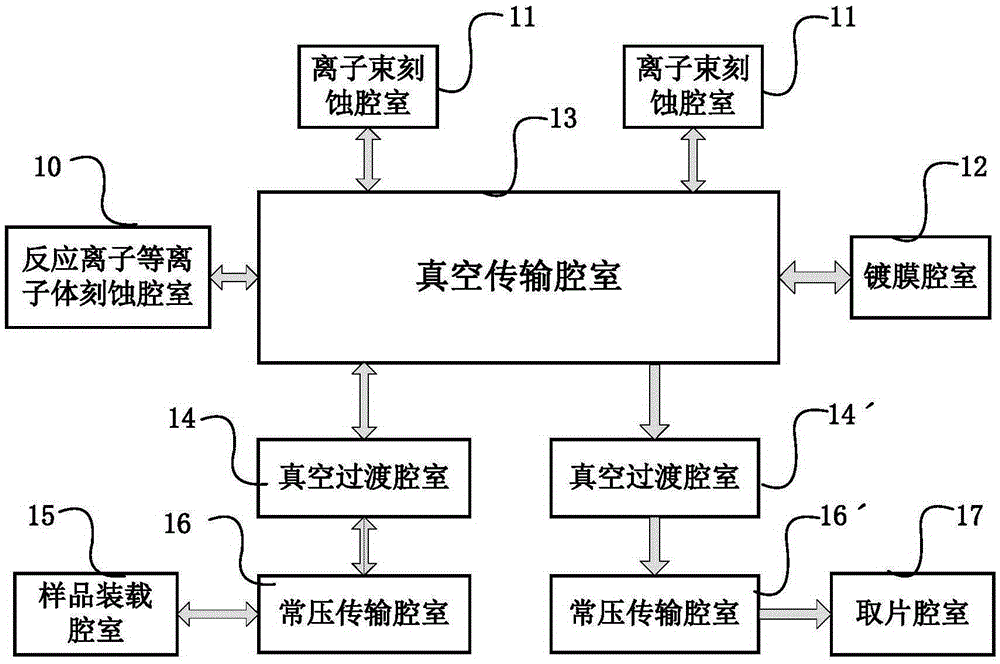

[0037] According to the first embodiment of the present invention, the metal etching device includes a reactive ion plasma etching chamber 10, an ion beam etching (IBE) chamber 11, a coating chamber 12, a vacuum transport chamber 13, a vacuum Transition chamber 14 ( figure 1 Not shown in ) and sample loading chamber 15. Wherein, the vacuum transition chamber 14 is respectively connected with the sample loading chamber 15 and the vacuum transmission chamber 13 in a communicable manner. The reactive ion plasma etching chamber 10 , the ion beam etching chamber 11 , and the coating chamber 12 are respectively connected to the vacuum transmission chamber 13 in a communicable manner. In addition, each of the above-mentioned chambers may also be multiple. figure 1 , figure 2 Two ion beam etching chambers 11 are shown in .

[0038] The metal etching device may also include an atmospheric pressure transmission chamber 16 ( figure 1 not shown in ), which are respectively connected...

no. 2 example

[0043] According to the second embodiment of the present invention, the metal etching device also includes a slice chamber 17, a vacuum transition chamber 14' ( figure 1 not shown in ), wherein, the taking-out chamber 17 is connected to the vacuum transition chamber 14' and the vacuum transfer chamber 13 in turn in a communicable manner. In addition, the metal etching device may also include a normal pressure transmission chamber 16' ( figure 1 not shown in ), which are respectively connected to the film taking chamber 17 and the vacuum transition chamber 14' in a communicable manner. Except for the above differences, the structures of other parts are the same as those of the first embodiment, and will not be described in detail again.

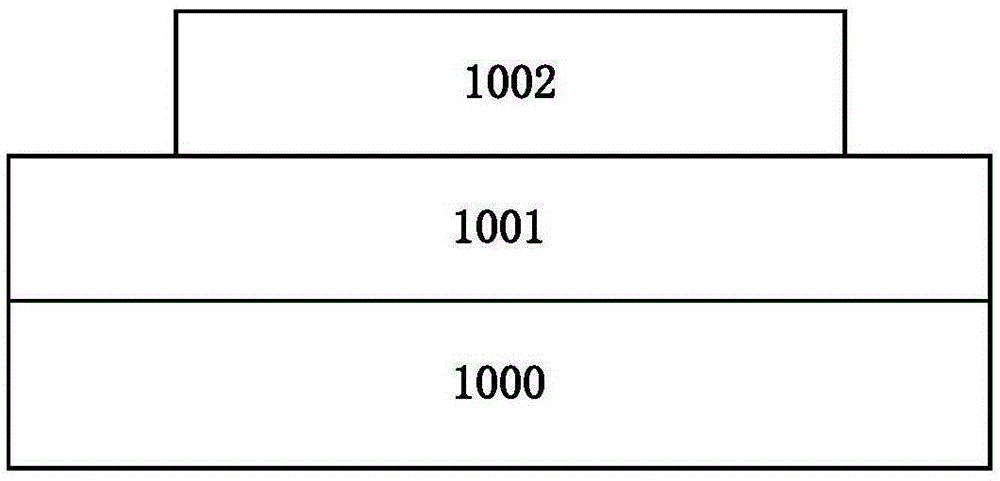

[0044] According to another aspect of the present invention, a metal etching method is provided. A detailed description will be given below in conjunction with the accompanying drawings. Figure 4 It is a flowchart showing the process flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com