Heat recovery four-stroke four-cylinder-driven turbine power generation system

A power generation system, four-stroke technology, applied to engine components, combustion engines, machines/engines, etc., can solve problems such as difficult performance guarantee, difficult mass production, permanent magnet generator demagnetization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

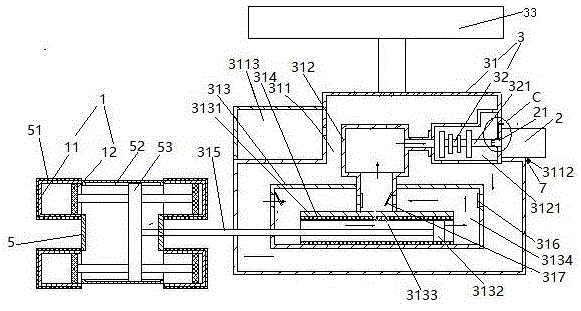

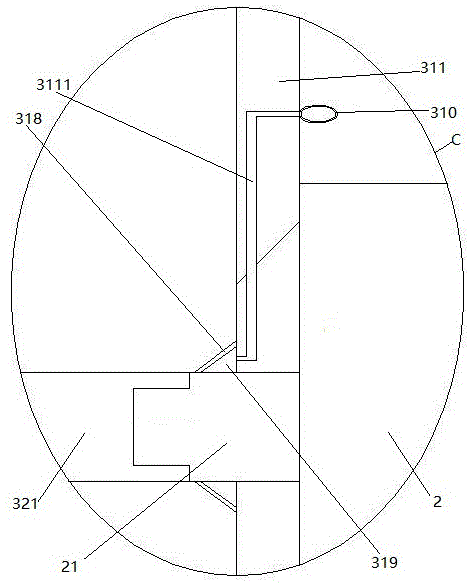

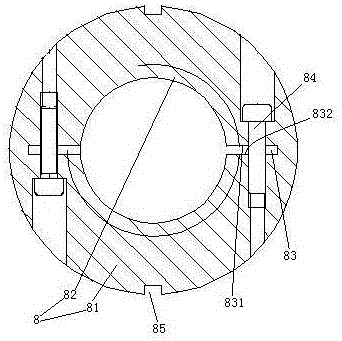

[0028] Embodiment one, see figure 1 , a heat recovery four-stroke four-cylinder drive turbine power generation system, including an engine cylinder 1, a generator 2 and a turbine system 3.

[0029] Engine cylinder 1 has four and is a four-stroke cylinder. Four engine cylinders 1 are connected together by a cylinder frame 5 . The cylinder block 11 of the engine cylinder is set in the high temperature end of the first thermoelectric power generation tube 51, and according to the layout of the four engine cylinders, the high temperature end of one first thermoelectric power generation tube 51 can simultaneously cover the cylinder blocks of four engine cylinders It is also possible to set four first thermoelectric power generation tubes so that the high temperature ends of the four first thermoelectric power generation tubes are sleeved on the cylinder blocks of the four engine cylinders in a one-to-one correspondence. The power output terminal of the first thermoelectric generato...

Embodiment 2

[0035] Embodiment two, the difference with embodiment one is:

[0036] see Figure 4 , The cylinder frame 5 is provided with a vibration isolation seat 4 and a vibration frequency detection device 56 . The vibration frequency detection device 56 is used to detect the frequency of the vibration generated by the cylinder frame 5 . The vibration frequency detection device 56 is a conventional frequency detection device. The vibration frequency detection device 56 and the control unit 55 are electrically connected together.

[0037] The vibration isolation base 4 includes a vertical vibration isolation spring 41 , a vertical support rod 42 , an ejector block lifting motor 43 , an upper connector 44 and a lower connector 45 . The upper end of the vibration isolation spring 41 is connected with the upper connecting head 44 . The vibration isolation spring 41 is sheathed on the support rod 42 . The vibration isolation spring 41 is a compression spring. The lower end of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com