Gas sensor array and manufacturing method thereof

A gas sensor and array technology, which is applied in semiconductor/solid-state device components, gaseous chemical plating, and manufacturing microstructure devices, etc., can solve the problems of insufficient sensitivity and selectivity, and achieve adjustable printing thickness, adjustable types, Ease of extraction of measured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

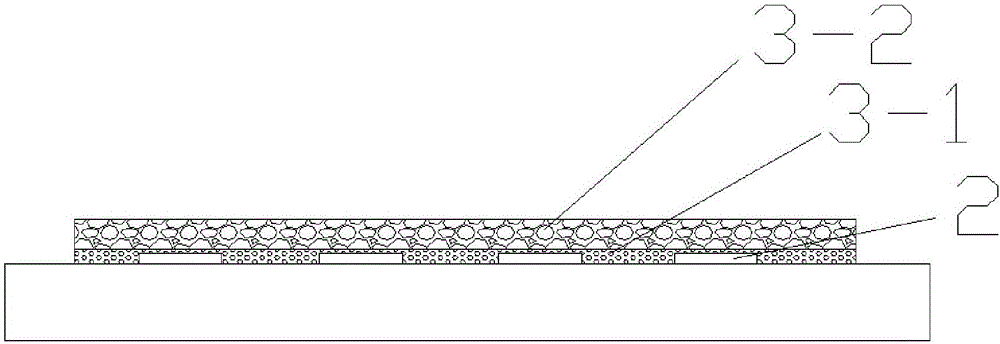

[0043] In another embodiment, a method for preparing the gas sensor array includes the following steps:

[0044] (1) A patterned metal electrode array is processed on the substrate, which is used as the conductive lead of each resistive gas sensor;

[0045] (2) transferring the graphene film to the substrate, and patterning the graphene film to form each gas-sensitive resistor in the array;

[0046] (3) Covering the polymer film on the graphene film, wherein the film types and / or film thicknesses of the polymer films of each gas sensor are different.

[0047]In a preferred embodiment, in step (1), a patterned metal electrode array is processed on the substrate by a lift-off process.

[0048] In a preferred embodiment, in step (2), the graphene film is prepared by a chemical vapor deposition (CVD) process and then transferred to the substrate, and the graphene on the substrate is patterned by plasma etching.

[0049] In a more preferred embodiment, in step (2), a graphene fil...

example 1

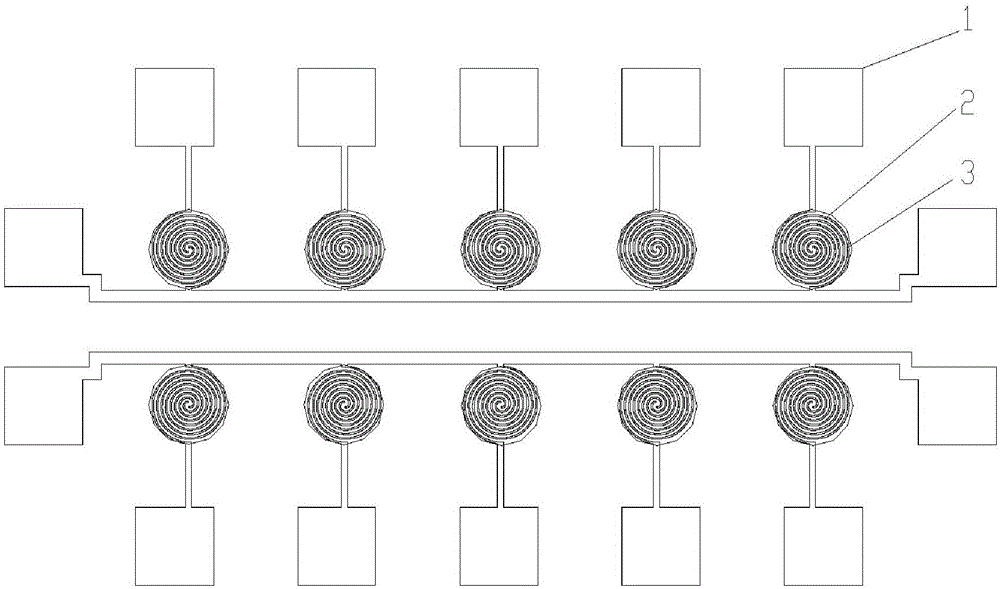

[0057] The substrate is a silicon oxide sheet, and the metal electrode is a spiral aluminum electrode. The schematic diagram of its structure is as follows: figure 1 shown. A spiral electrode array is processed on the substrate by a photolithographic lift-off process to form the conductive leads of each gas-sensitive resistor; graphene is prepared by a chemical vapor deposition (CVD) process, transferred to the electrode, and the graphite is etched by plasma Graphene is patterned to form individual gas-sensitive resistors in the array; different types of polymers are printed on the sensitive areas of each sensor through an inkjet printing process, and dried to form a polymer film.

example 2

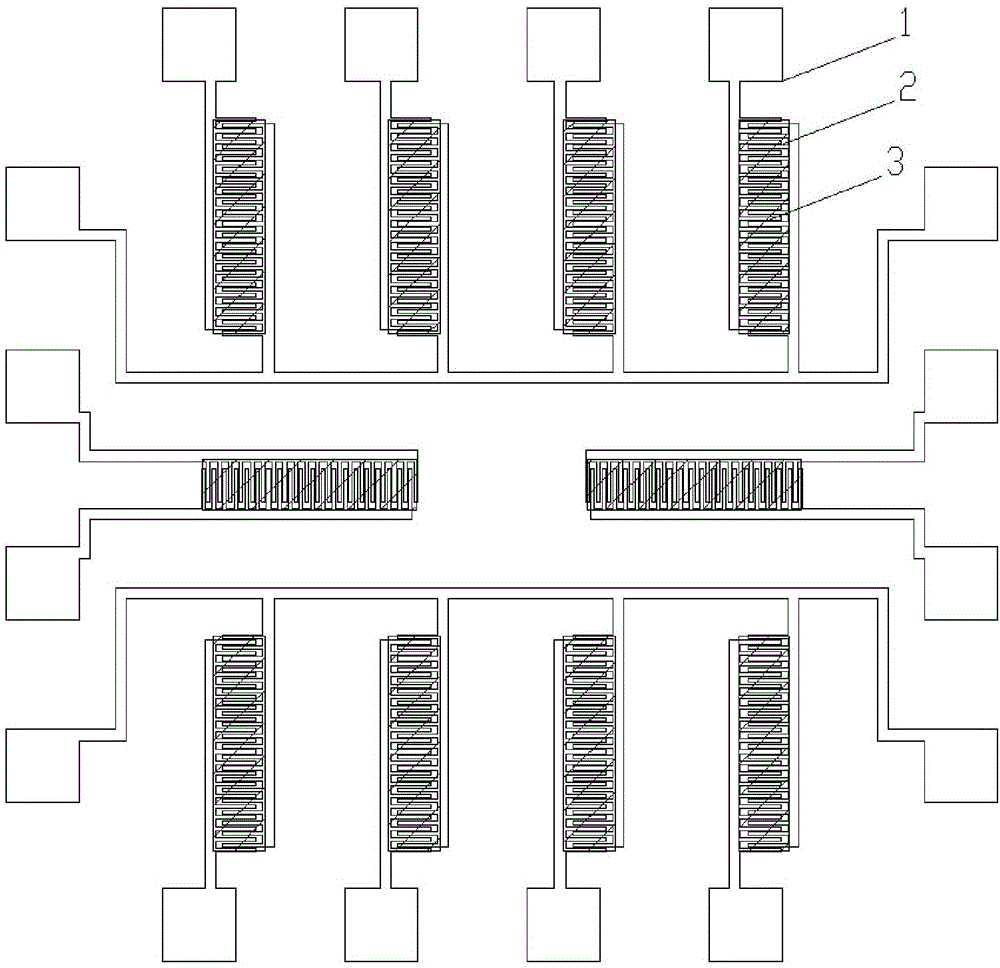

[0059] The substrate is a silicon oxide sheet, and the metal electrode is an interdigitated aluminum electrode. The schematic diagram of its structure is as follows: figure 2 shown. The interdigitated electrode array is processed on the substrate through the photolithography lift-off process to form the conductive leads of each gas sensitive resistor; the graphene is prepared by the chemical vapor deposition (CVD) process, transferred to the electrode, and used for plasma etching. Graphene is patterned to form each gas-sensitive resistor in the array; different types of polymers are printed on the sensitive areas of each sensor through an inkjet printing process, and dried to form a polymer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com