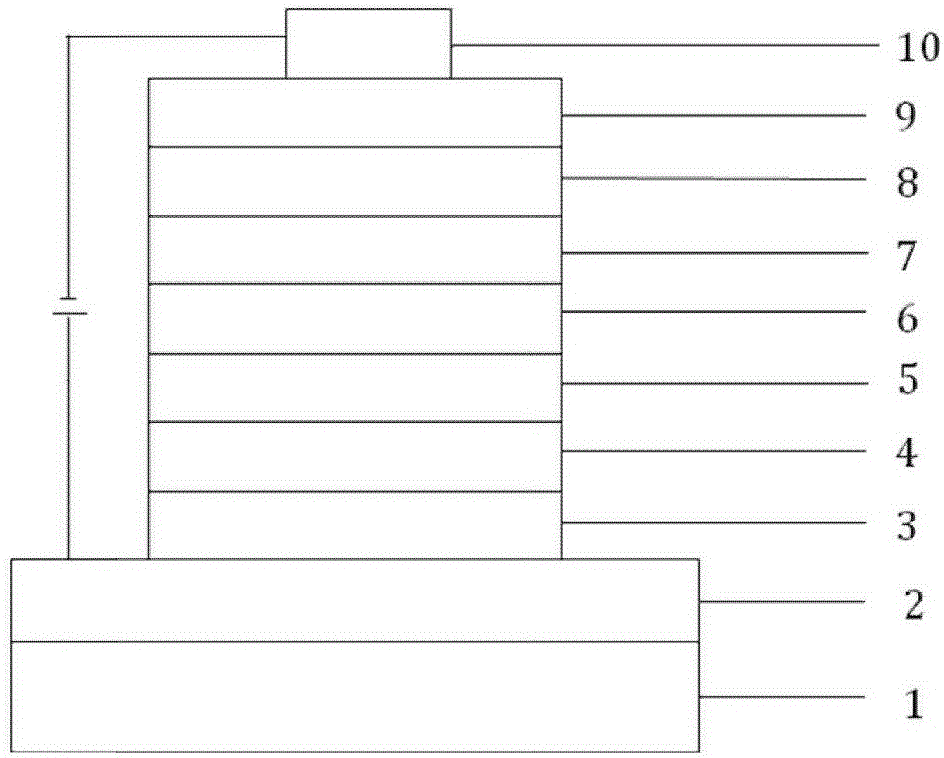

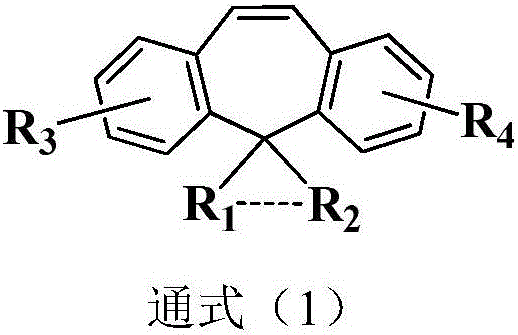

Organic electroluminescent device containing chemical compound with dibenzocycloheptene as its core and the application thereof

A technology of dibenzocycloheptene and electroluminescent devices, which is applied in the field of semiconductors and can solve very different problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

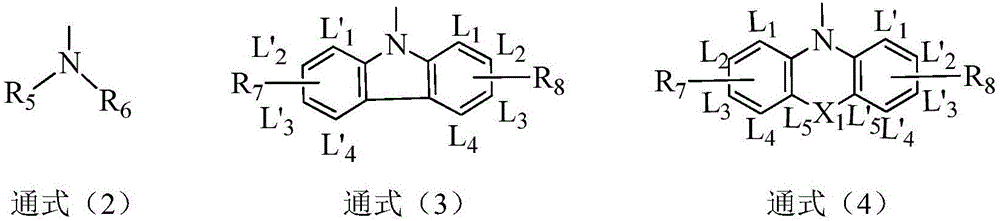

[0101] Embodiment 1: the synthesis based on the intermediate I of mother core structure and the branched chain structure intermediate II based on general formula (2)

[0102] a. Synthesis of intermediate I based on the core structure: when R 1 with R 2 When not connected into a ring, the synthesis of intermediate I is:

[0103]

[0104]

[0105] Above-mentioned preparation method specifically comprises the following steps:

[0106] 1)R 1 -Br and magnesium powder as raw materials, the R 1 -The molar ratio of Br and magnesium powder is 1:1, add tetrahydrofuran, under nitrogen atmosphere, heat to 70°C, reflux reaction for 3-5 hours, no magnesium powder remains, the reaction is complete, and Grignard reagent is generated; the amount of tetrahydrofuran mentioned above preferably 1gR 1 -Br add 3-6ml tetrahydrofuran,

[0107] 2) Weigh raw material U Dissolved in tetrahydrofuran, the raw material U and the R 1 -Br molar ratio is 1:1, then add the Grignard reagent prepar...

Embodiment 2

[0140] Embodiment 2: the synthesis of compound 1:

[0141]

[0142] In a 250ml three-neck flask, under the protection of nitrogen, add 0.01mol intermediate A1, 0.024mol intermediate C1, 150ml toluene and stir to mix, then add 0.04mol sodium tert-butoxide, 1×10 -4 molPd 2 (dba) 3 , 1×10 -4 mol of tri-tert-butylphosphine, heated to 105°C, refluxed for 24 hours, sampling plate, showed no remaining bromide, the reaction was complete; naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated under reduced pressure (-0.09MPa, 85°C ), through a neutral silica gel column, to obtain the target product, HPLC purity 99.5%, yield 66.8%;

[0143] Elemental analysis structure (molecular formula C 51 h 38 N 2 ): theoretical value C, 90.23; H, 5.64; N, 4.13; test value: C, 90.24; H, 5.65; N, 4.11. HPLC-MS: The molecular weight of the material is 678.30, and the measured molecular weight is 678.57.

Embodiment 3

[0144] Embodiment 3: the synthesis of compound 3:

[0145]

[0146] In a 250ml three-neck flask, under the protection of nitrogen, add 0.01mol intermediate A1, 0.024mol intermediate C2, 150ml toluene and stir to mix, then add 0.04mol sodium tert-butoxide, 1×10 -4 molPd 2 (dba) 3 , 1×10 -4 mol of tri-tert-butylphosphine, heated to 105°C, refluxed for 24 hours, sampling plate, showed no remaining bromide, the reaction was complete; naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated under reduced pressure (-0.09MPa, 85°C ), through a neutral silica gel column, to obtain the target product, HPLC purity 99.7%, yield 64.4%;

[0147] Elemental analysis structure (molecular formula C 69 h 54 N 2 o 2 ): theoretical value C, 87.87; H, 5.77; N, 2.97; 0, 3.39; test value: C, 87.86; HPLC-MS: The molecular weight of the material is 942.42, and the measured molecular weight is 942.71.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com