A kind of self-emulsifying coenzyme q10 oil agent and its preparation method and application

An emulsifier and self-emulsifying technology, which is applied in the digestive system, pharmaceutical formulations, oil/fat/wax non-effective ingredients, etc., can solve the problems of bioavailability without clear instructions, small solubility and easy crystallization, and product Technical defects and other problems, to achieve the effect of being conducive to preparation and preservation, simple preparation method, and improved absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

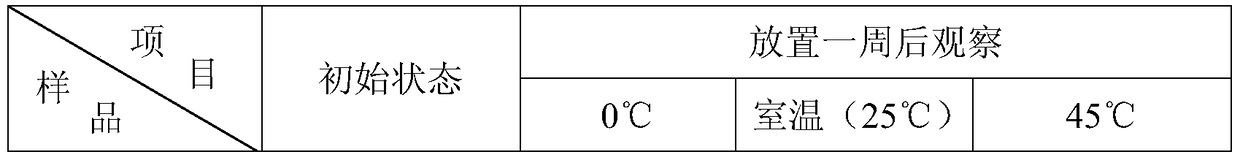

Examples

Embodiment 1

[0039] Preparation of coenzyme Q10 and DHA self-emulsifying oil (can compress 1000,000 soft capsules containing 50mg of coenzyme Q10 and 100mg of DHA)

[0040] Coenzyme Q10: 50kg

[0041] DHA oil: 225kg

[0042] THL-15: 2.5kg

[0043] Ascorbyl palmitate: 9kg

[0044] Span 80: 10kg

[0045] Tween 80: 138.5kg

[0046] Poloxamer 168: 15kg

[0047] By weighing the components with the above weight, prepare coenzyme Q10 and DHA self-micronizing oil according to the following operations: add coenzyme Q10 and olive oil to DHA oil, then add oil phase emulsifier Span 80 and functional additive THL -15, avoid light, evacuate and replenish nitrogen for three times, heat and stir until the solid material is completely dissolved; then add the main emulsifier Tween 80 and Poloxamer 168. Heat at 60-65°C and stir until the final system is uniform and transparent, then keep warm for 10-30 minutes, and the final product can be obtained after cooling down. The final product obtained is an ...

Embodiment 2

[0049] Preparation of coenzyme Q10 and DHA self-emulsifying oil (can compress 1000,000 soft capsules containing coenzyme Q10 100mg, DHA 200mg No. 18 soft capsules), prepared coenzyme Q10 and DHA self-emulsifying oil by the same operation as described in Example 1 , but the following self-emulsifying system components are used.

[0050] Coenzyme Q10: 100kg

[0051] DHA oil: 400kg

[0052] THL-15: 5kg

[0053] Ascorbyl palmitate: 15kg

[0054] Span 80: 20kg

[0055] Tween 80: 240kg

[0056] Poloxamer 188: 20kg

[0057] The final product obtained is an orange-red transparent and uniform oil, which can be used as the content of microcapsules. Coenzyme Q10 / DHA soft capsules are obtained through soft capsule production equipment, and 1,000,000 No. 18 soft capsules can be prepared from the above-mentioned total content. Among them, the No. 18 soft capsule contains 800 mg of content, 100 mg of coenzyme Q10, and 200 mg of DHA (the content of coenzyme Q10 is determined by the met...

Embodiment 3

[0059] Preparation of coenzyme Q10 and ARA self-emulsifying oil (can compress 1000,000 soft capsules containing 50 mg of coenzyme Q10 and No. 100 mg of ARA), and prepare coenzyme Q10 and ARA self-emulsifying oil by the same operation as described in Example 1 , but the following self-emulsifying system components are used.

[0060] Coenzyme Q10: 50kg

[0061] ARA oil: 225kg

[0062] THL-17: 3kg

[0063] Ascorbyl palmitate: 9kg

[0064] Glyceryl monostearate: 15kg

[0065] Polyoxyethylene hydrogenated castor oil fatty acid ester: 133kg

[0066] Poloxamer 168: 15kg

[0067] The final product obtained is an orange-red transparent and uniform oil, which can be used as the content of microcapsules. Coenzyme Q10 / ARA soft capsules are obtained through soft capsule production equipment, and the above-mentioned total content can be used to prepare 1,000,000 No. 10 soft capsule products. The No. 10 soft capsule contains 450mg of content, 50mg of coenzyme Q10, and 100mg of ARA (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com