Aqueous positive paste and preparation method thereof

A positive electrode slurry and water-based technology, applied in the field of electrochemistry, can solve the problems of poor flexibility, poor fluidity, and poor stability of the positive electrode sheet, and achieve the effects of improving electrochemical performance, reducing battery internal resistance, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

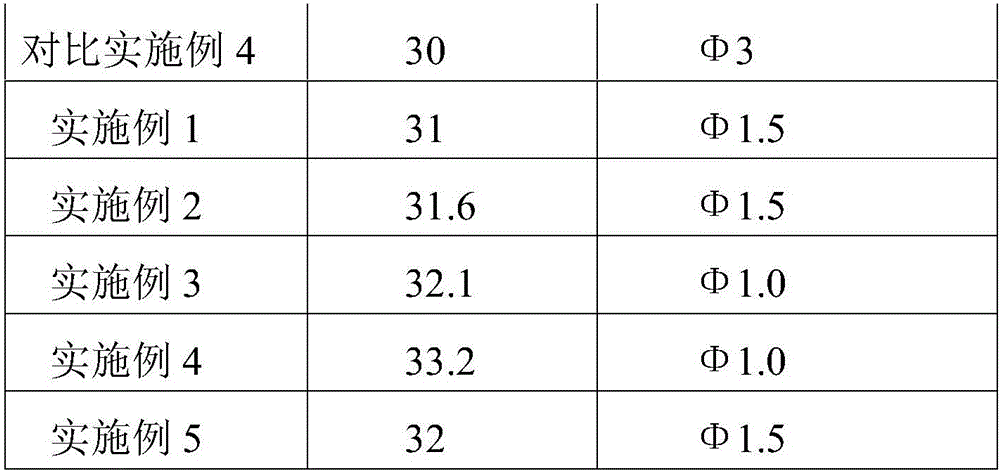

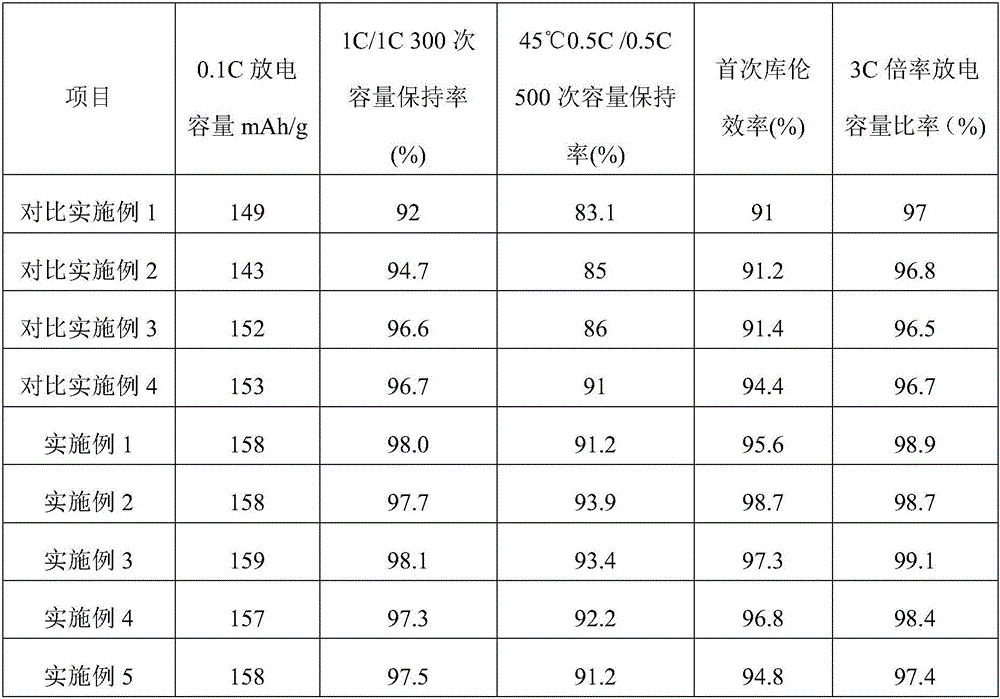

Examples

Embodiment 1

[0043] This embodiment provides a kind of water-based positive electrode slurry, positive electrode sheet and lithium ion battery and its preparation:

[0044] One, the preparation of aqueous positive electrode slurry, comprises the steps:

[0045] Step 1. Add 0.4 parts by weight of polyvinylpyrrolidone (PVP), 0.5 parts by weight of ethylene carbonate and 10 parts by weight of deionized water to the mixer, stir at a medium speed of 800rpm for 0.5h, and obtain glue A after stirring evenly;

[0046] Step 2: Add 5 parts by weight of LA133 and 40 parts by weight of deionized water into the mixer, stir at a medium speed of 800rpm for 0.5h, and obtain glue B after stirring evenly;

[0047] Step 3: Add glue A, 2 parts by weight of conductive carbon black, and 1 part by weight of conductive graphite to glue B, and stir at a high speed of 1500 rpm for 90 minutes;

[0048] Step 4: Add two equal parts of 92 parts by weight of nano-lithium iron phosphate into the agitator in turn, and th...

Embodiment 2

[0058] This embodiment provides a kind of water-based positive electrode slurry, positive electrode sheet and lithium ion battery and its preparation:

[0059] One, the preparation of aqueous positive electrode slurry, comprises the steps:

[0060] Step 1. Add 0.5 parts by weight of polyvinylpyrrolidone (PVP), 0.8 parts by weight of ethylene carbonate and 10 parts by weight of deionized water into the mixer, stir at a medium speed of 800 rpm for 0.5 h, and obtain glue A after stirring evenly;

[0061] Step 2: Add 3.5 parts by weight of LA133 and 40 parts by weight of deionized water into the mixer, stir at a medium speed of 800rpm for 0.5h, and obtain glue B after stirring evenly;

[0062] Step 3: Add glue A, 2 parts by weight of conductive carbon black, and 1 part by weight of conductive graphite to glue B, and disperse at a high speed of 1500 rpm for 90 minutes;

[0063] Step 4: Add two equal parts of 92 parts by weight of nano-lithium iron phosphate into the agitator in tu...

Embodiment 3

[0069] This embodiment provides a kind of water-based positive electrode slurry, positive electrode sheet and lithium ion battery and its preparation:

[0070] One, the preparation of aqueous positive electrode slurry, comprises the steps:

[0071] Step 1. Add 0.8 parts by weight of polyvinylpyrrolidone (PVP), 1 part by weight of ethylene carbonate and 10 parts by weight of deionized water into the mixer, stir at a medium speed of 800rpm for 0.5h, and obtain glue A after stirring evenly;

[0072] Step 2: Add 5 parts by weight of LA133 and 40 parts by weight of deionized water into the mixer, stir at a medium speed of 800rpm for 0.5h, and obtain glue B after stirring evenly;

[0073] Step 3. Add glue A, 2 parts by weight of conductive carbon black, and 1 part by weight of conductive graphite to the glue solution B, and disperse and stir at a high speed for 90 minutes at a speed of 1500 rpm;

[0074] Step 4: Add two equal parts of 92 parts by weight of nano-lithium iron phospha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com