Adsorptive regeneration device with solid-liquid phase change matters and adsorptive regeneration process

A solid-liquid phase change and regeneration device technology, which is applied in the field of adsorption regeneration devices and adsorption regeneration technology, can solve the problems of increasing system complexity, difficulty in oil and gas desorption, and increasing operating costs, and achieve volume reduction, large heat absorption, and The effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

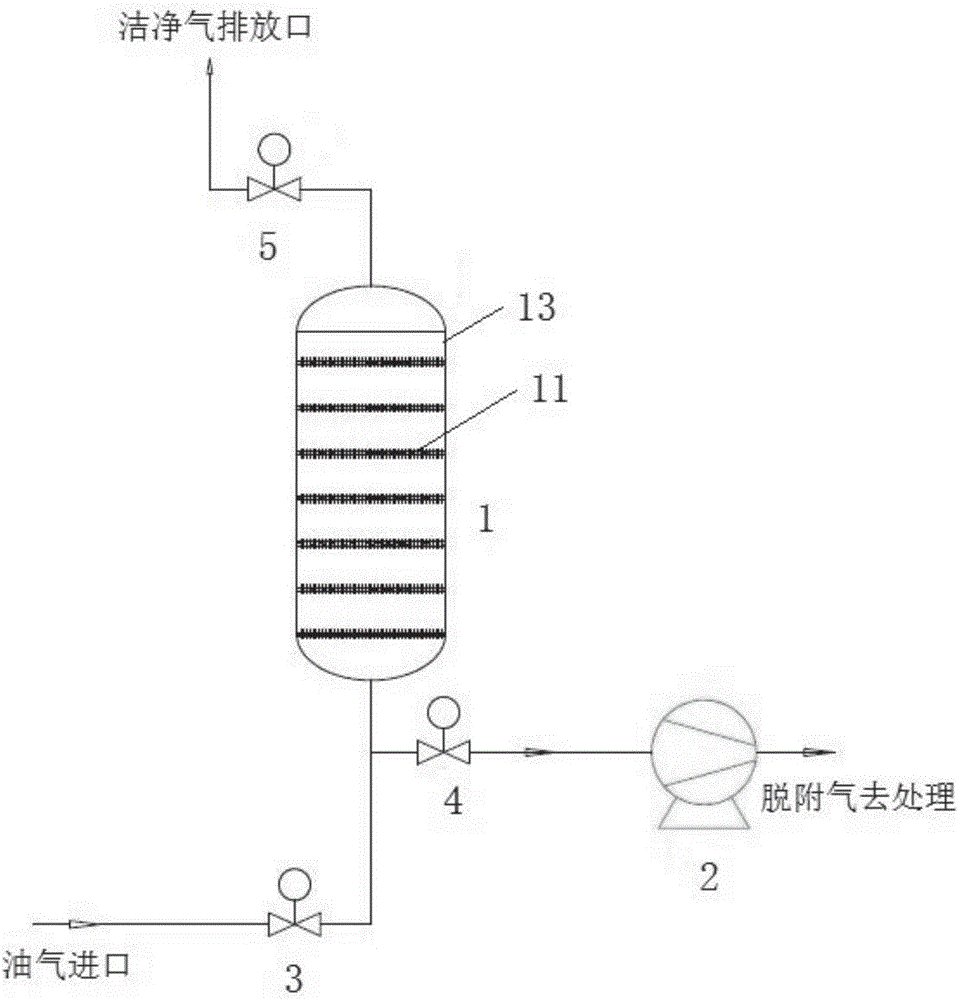

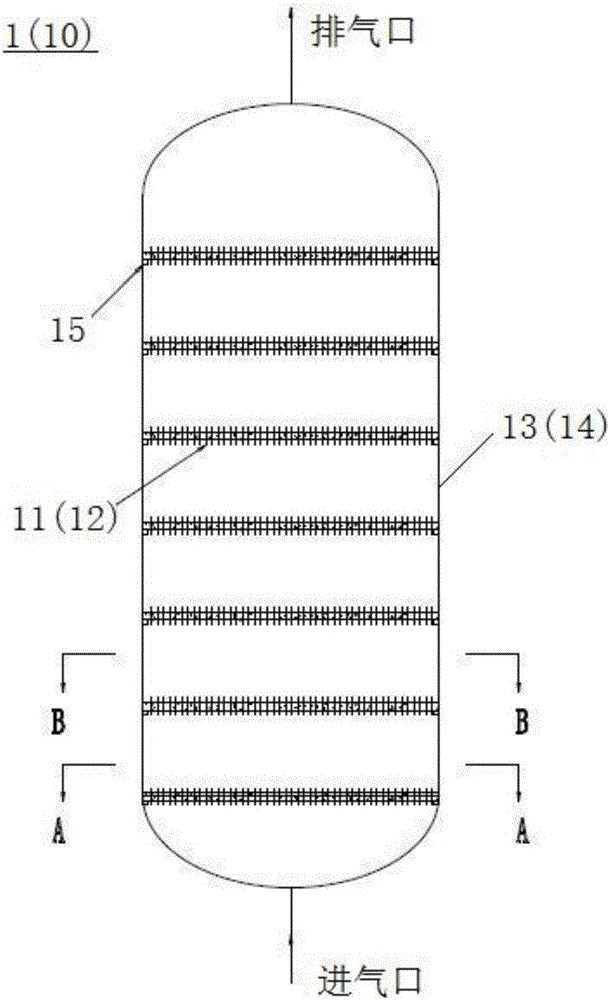

[0078] Such as figure 1 As shown, the present invention discloses an adsorption regeneration device with a solid-liquid phase change substance, including an oil gas inlet, a first adsorption tank 1, a first heat exchange tube 11, a vacuum pump 2, a first oil gas inlet valve 3, a first vacuum Valve 4, first oil and gas outlet valve 5, clean gas discharge port, wherein:

[0079] The first heat exchange tube 11 is arranged inside the first adsorption tank 1, and its inside is a hollow structure filled with a solid-liquid phase change energy storage material;

[0080] The oil and gas inlet is sequentially connected with the first oil and gas inlet valve 3, the first adsorption tank 1, the first oil and gas outlet valve 5 and the clean gas discharge port;

[0081] One end of the first vacuum valve 4 is connected between the first oil inlet valve 3 and the first adsorption tank 1 , and the other end is connected with the vacuum pump 2 .

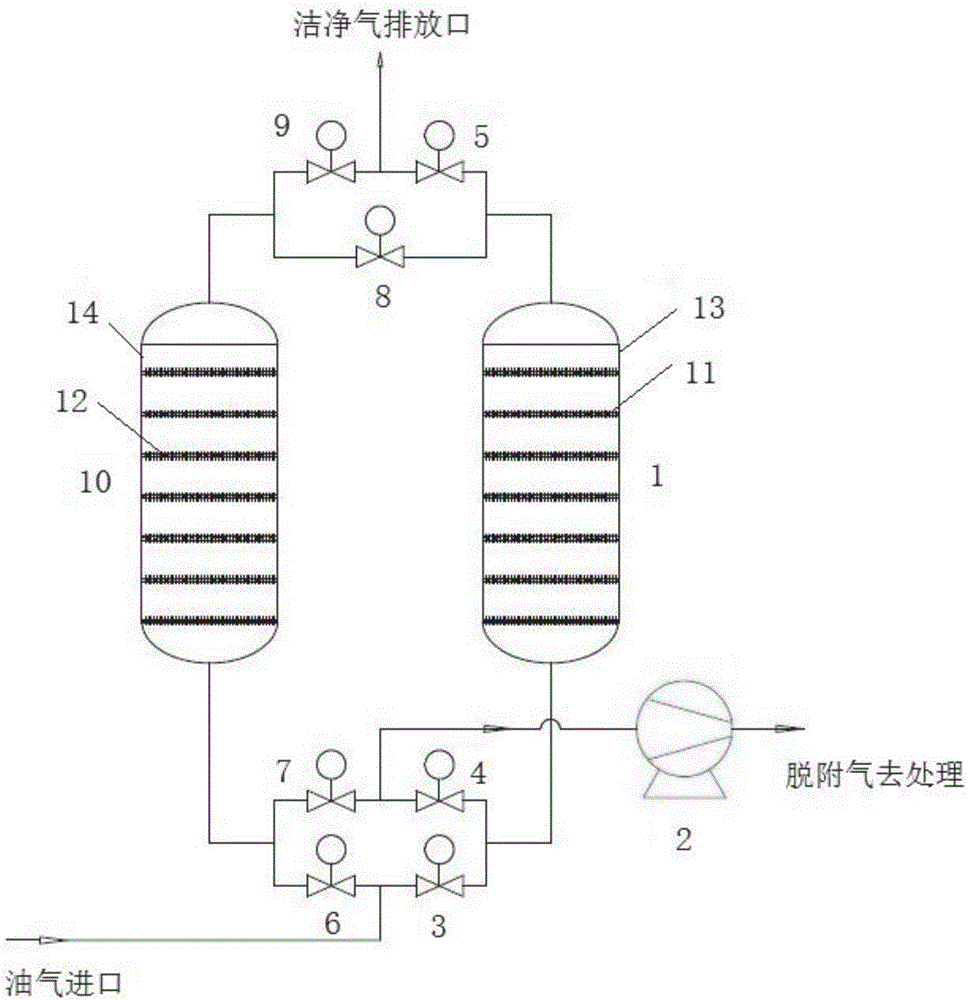

[0082] Such as figure 2 As shown, the ad...

Embodiment 2

[0102] Such as Figure 6 As shown, the present invention also discloses an adsorption regeneration process with a solid-liquid phase change substance, comprising the following steps:

[0103] Step 1: The oil and gas to be treated enters through the oil and gas inlet, enters the first adsorption tank 1 through the first oil and gas inlet valve 3, and is absorbed and intercepted by the first adsorbent in the first adsorption tank 1, and the solid-liquid phase change substance passes through the fins The tube absorbs a large amount of adsorption heat to make the solid-liquid phase change material change from solid to liquid, stabilizing the adsorption temperature, and the remaining clean exhaust gas is heated by the remaining small amount of adsorption heat and then discharged into the atmosphere through the first oil and gas outlet valve 5, and the first adsorption tank 1 absorbs oil and gas At the same time, the second adsorption tank 10 is regenerating, and the alternating tim...

Embodiment 3

[0107] Such as Figure 7 As shown, the present invention additionally discloses an adsorption regeneration process with a solid-liquid phase change substance, comprising the following steps:

[0108] Step A: The oil and gas to be treated enter through the oil and gas inlet, the oil and gas enter the second adsorption tank 10 through the second oil and gas inlet valve 6, and are absorbed and intercepted by the second adsorbent in the second adsorption tank 10, and the solid-liquid phase change material passes through the fins The tube absorbs a large amount of adsorption heat to make the solid-liquid phase change material change from solid to liquid, stabilizing the adsorption temperature, and the remaining clean exhaust gas is heated by the remaining small amount of adsorption heat and then discharged into the atmosphere through the second oil and gas outlet valve 9, and the second adsorption tank 10 absorbs oil and gas At the same time, the first adsorption tank 1 is regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com