A preparation method of calcium-doped titanium dioxide nanofiber photocatalyst

A nanofiber and titanium dioxide technology, which is applied in the field of preparation of titanium dioxide nanofiber photocatalyst, can solve the problems of limiting the application in the field of photocatalysis, and achieve the effect of improving the photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Add 1mL of acetic acid and 1.1g of polyvinylpyrrolidone to 9mL of ethanol solution, and form a transparent solution A after stirring;

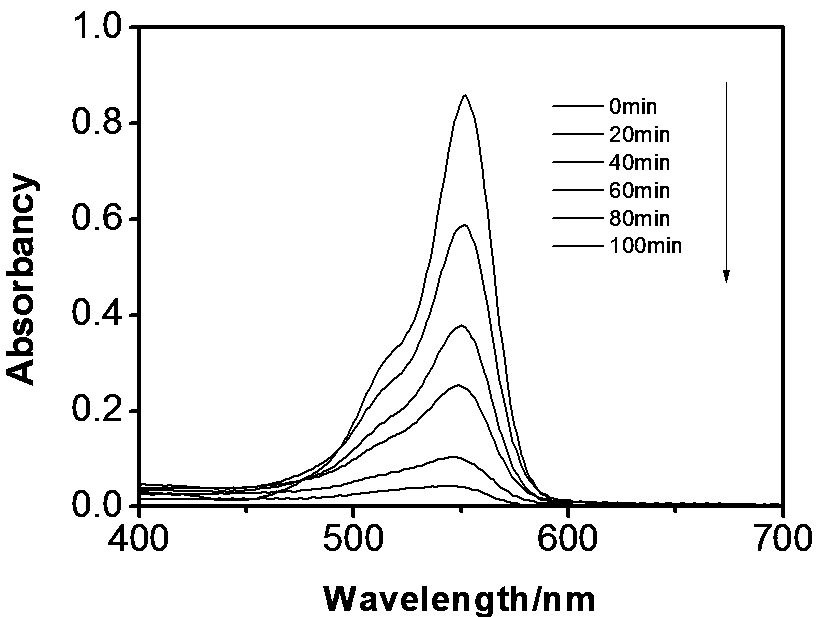

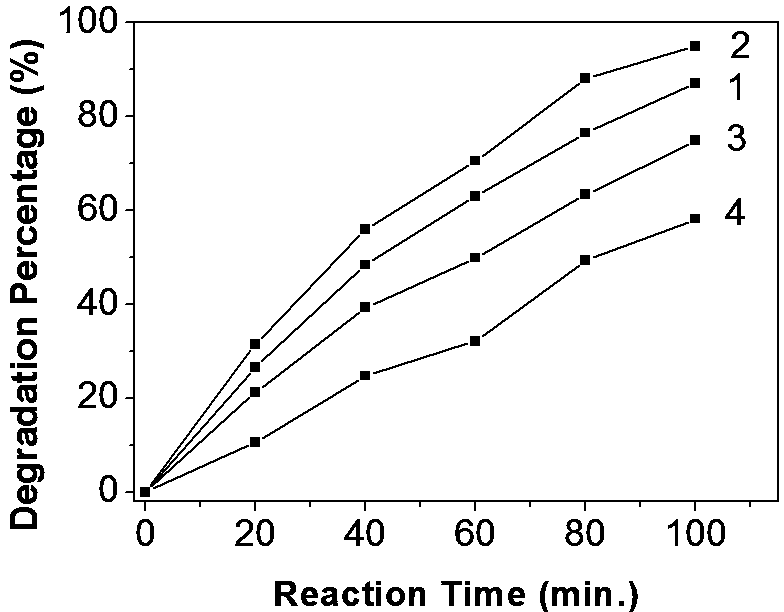

[0014] (2) Add 0.9mL isopropyl titanate and 0.01g calcium acetate to the solution A prepared in (1); after stirring evenly, a transparent sol solution B is obtained; (3) Electrospin the sol solution B prepared above Silk. The prepared electrospun sample was dried at room temperature for 48 hours, then placed in a high-temperature furnace, kept at 600°C for 24 hours, and cooled naturally to room temperature to obtain Ca with excellent photocatalytic properties. 2+ Doped TiO 2 nanofiber photocatalyst. figure 1 The Ca prepared in Example 1 is given 2+ Doped TiO 2 Under the condition of 365nm ultraviolet light irradiation for 100 minutes, the nanofiber can almost condense the concentration of 1 × 10 -5 The mol / L rhodamine B aqueous solution was completely degraded, indicating that the obtained catalyst had excellent photocatalytic ...

Embodiment 2

[0016] (1) Add 2 mL of acetic acid and 1 g of polyvinylpyrrolidone to 8 mL of ethanol solution, and form a transparent solution A after stirring;

[0017] (2) Add 1mL of isopropyl titanate and 0.015g of calcium acetate to the solution A prepared in (1); stir evenly to obtain a transparent sol solution B; (3) Electrospin the sol solution B prepared above . The prepared electrospun sample was dried at room temperature for 60 hours, then placed in a high-temperature furnace, kept at 550°C for 30 hours, and cooled naturally to room temperature to obtain Ca with excellent photocatalytic properties. 2+ Doped TiO 2 Nanofiber photocatalysts, followed by photocatalytic experiments.

Embodiment 3

[0019] (1) Add 1.5mL acetic acid and 0.8g polyvinylpyrrolidone to 8.5mL ethanol solution, and form a transparent solution A after stirring;

[0020] (2) Add 2mL of isopropyl titanate and 0.02g of calcium acetate to the solution A prepared in (1); stir evenly to obtain a transparent sol solution B; (3) Electrospin the sol solution B prepared above . The prepared electrospun sample was dried at room temperature for 30 hours, then placed in a high-temperature furnace, kept at 650°C for 20 hours, and cooled naturally to room temperature to obtain Ca with excellent photocatalytic properties. 2+ Doped TiO 2 Nanofiber photocatalysts, followed by photocatalytic experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com