Preparation method and application of supported metal oxide catalyst for removing ammonia nitrogen in water through catalytic ozonation

A technology of ozone oxidation and metal loading, which is applied in the field of industrial water treatment to achieve the effect of easy industrialization, good catalytic ozone oxidation to remove ammonia nitrogen, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Co 3 o 4 -Al 2 o 3 Catalyst preparation

[0020] Select 3-5mm γ-Al 2 o 3 The microspheres are used as the catalyst carrier, washed twice with deionized water, then soaked overnight with 0.10mol / L dilute hydrochloric acid, finally washed with deionized water until the effluent is neutral, and dried at 100±2°C to obtain the activated γ-Al 2 o 3 microspheres; activated γ-Al 2 o 3 The microspheres are impregnated in a cobalt nitrate impregnation solution with a concentration of 0.05mol / L for 15 hours, then dried at 100±2°C for 4 hours, and then roasted at 600±10°C for 4 hours to obtain Co 3 o 4 -Al 2 o 3 catalyst.

Embodiment 2

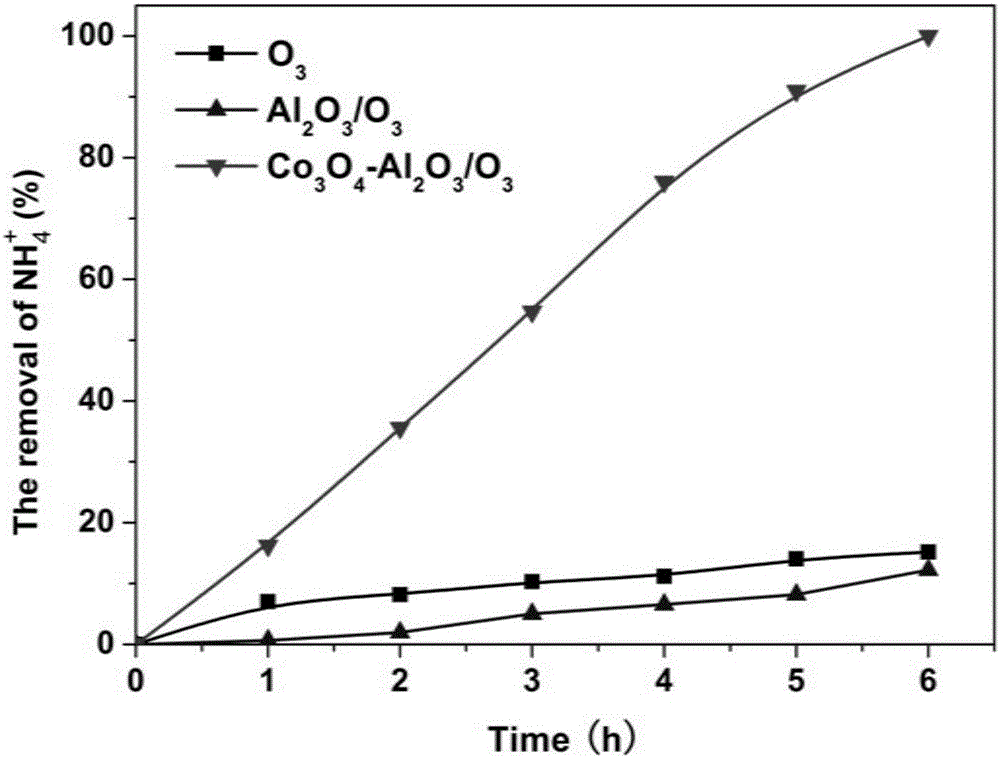

[0021] Example 2: Co 3 o 4 -Al 2 o 3 Catalytic Ozone Oxidation Performance of Catalyst

[0022] 100g of prepared Co 3 o 4 -Al 2 o 3 Catalyst loaded as attached figure 1 In the reaction device shown, add 1.0L, 200mg / L ammonium chloride simulated waste water, control the reaction temperature at 25°C by water bath circulation, feed ozone gas, the gas flow rate is 1.0L / min, and the concentration is 2.4mg / L , take samples at intervals of 1h to measure the concentration of ammonia nitrogen in the solution, and react for 6h to complete the catalytic ozonation process. For comparison, the γ-Al 2 o 3 Blank spheres and ozone alone repeat the above ozone oxidation process. Experimental reaction 6h, with Co 3 o 4 -Al 2 o 3 When used as a catalyst, the removal rate of ammonia nitrogen is close to 100%, while adding γ-Al 2 o 3 The removal rates of ammonia nitrogen were only 15% and 18% for the blank sphere and the ozone process alone, which indicated that the prepared Co 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com