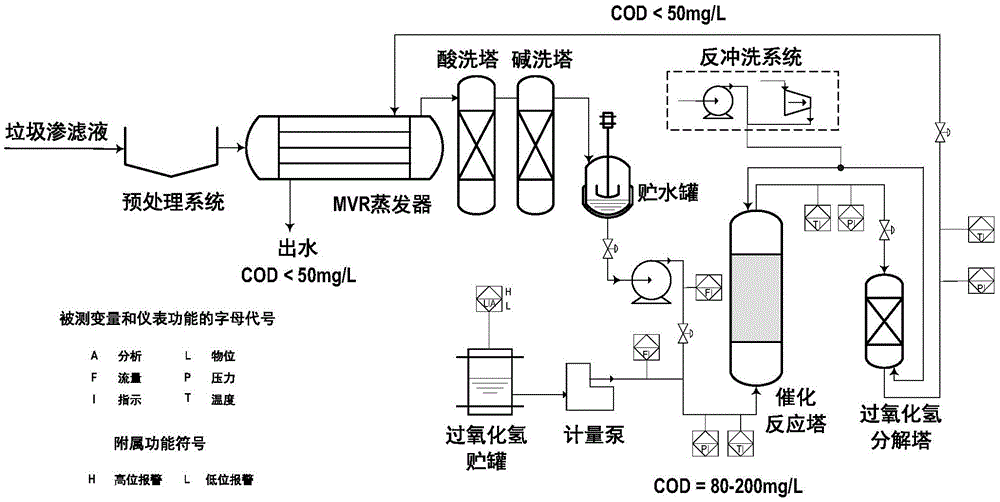

Combined landfill leachate treatment process

A landfill leachate and treatment process technology, applied in landfill leachate degradation, MVR system field, can solve the problems of secondary pollution, high cost, and the effluent can not meet the water environment discharge standards, to avoid iron sludge, high thermal stability , the effect of good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

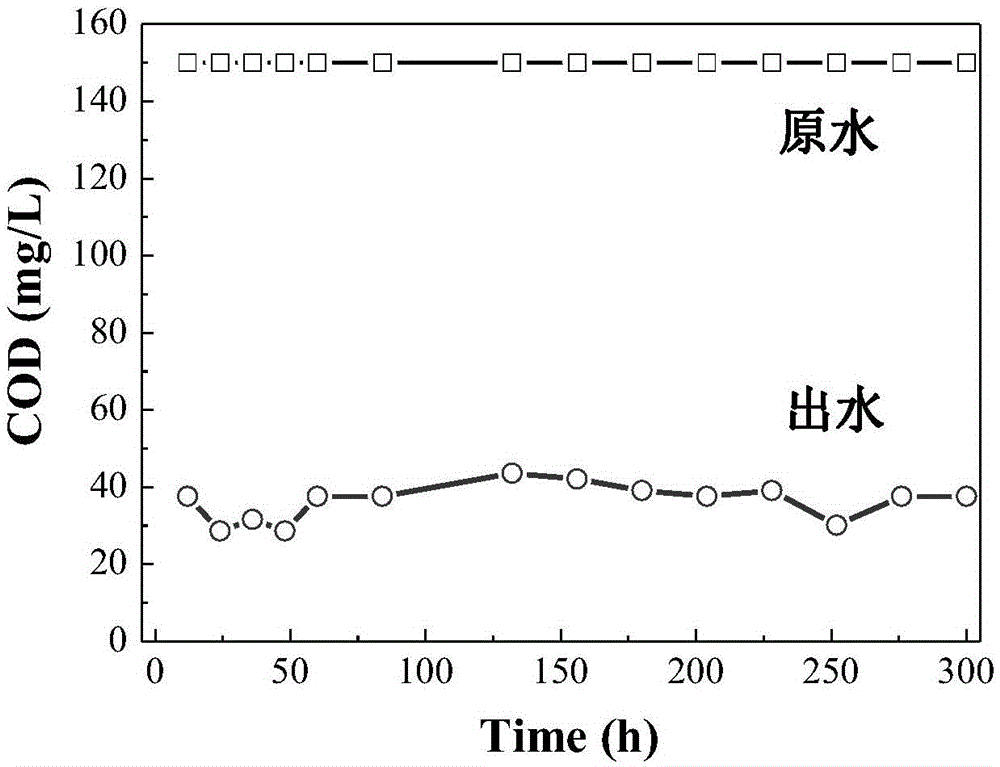

[0031] Taking leachate 60 tons / day as an example, COD of landfill leachate stock solution=40000~50000mg / L, NH 3 -N=1500~2000mg / L; COD=150~180mg / L of the condensate (about 90°C) after pretreatment and evaporation scrubbing, NH 3 -N=6~12mg / L, adjust the pH value to 6 in the water storage tank, and transport it to the bottom of the catalytic reaction tower; the catalyst in the catalytic reaction tower is 3wt.%Fe-0.5wt.%Mn / Al 2 o 3 , LHSV is 0.5h -1 , H 2 o 2 (mg / L): COD (mg / L) = 2.5; run for 300 hours, effluent COD = 20 ~ 40mg / L (such as figure 2 ), can directly meet the emission standards.

Embodiment 2

[0033] Taking leachate 600 tons / day as an example, landfill leachate stock solution COD=35000~40000mg / L, NH 3 -N=1000~1500mg / L; COD=80~120mg / L of the condensate (about 85°C) after pretreatment and evaporation scrubbing, NH 3 -N=8~15mg / L, adjust the pH value to 7 in the water storage tank, and transport it to the bottom of the catalytic reaction tower; the catalyst in the catalytic reaction tower is 3wt.%Fe-1wt.%Ce / Al 2 o 3 , LHSV is 1h -1 , H 2 o 2 (mg / L): COD (mg / L) = 3; after 200 hours of operation, the effluent COD = 40-45mg / L, which can be discharged directly up to the standard.

[0034] in conclusion:

[0035] The invention aims at the drawbacks and shortcomings of the existing landfill leachate treatment methods, integrates the heterogeneous catalytic wet hydrogen peroxide oxidation technology into the evaporation scrubbing system, and deeply degrades the landfill leachate. The reaction conditions are mild and can effectively remove COD and chroma of wastewater wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com