Resin lens with ultraviolet photocuring refractive index of 1.56 and production method thereof

A technology of resin lenses and ultraviolet rays, applied in optics, optical components, optical components, etc., can solve problems such as long polymerization time, large internal stress, and general optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

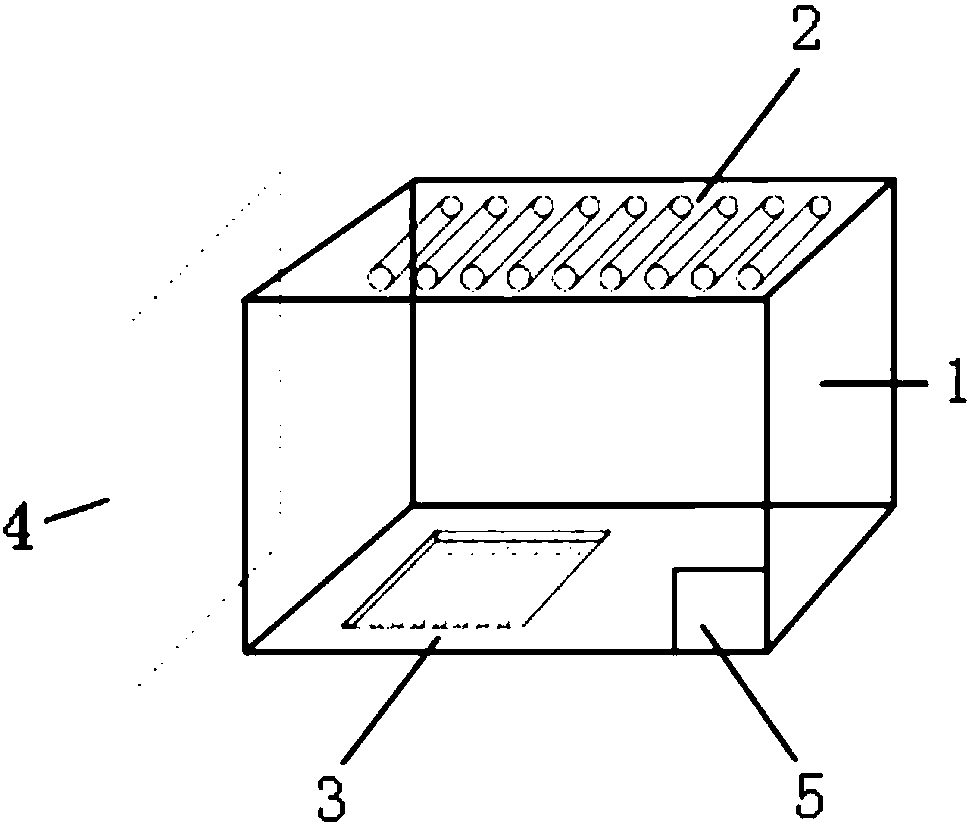

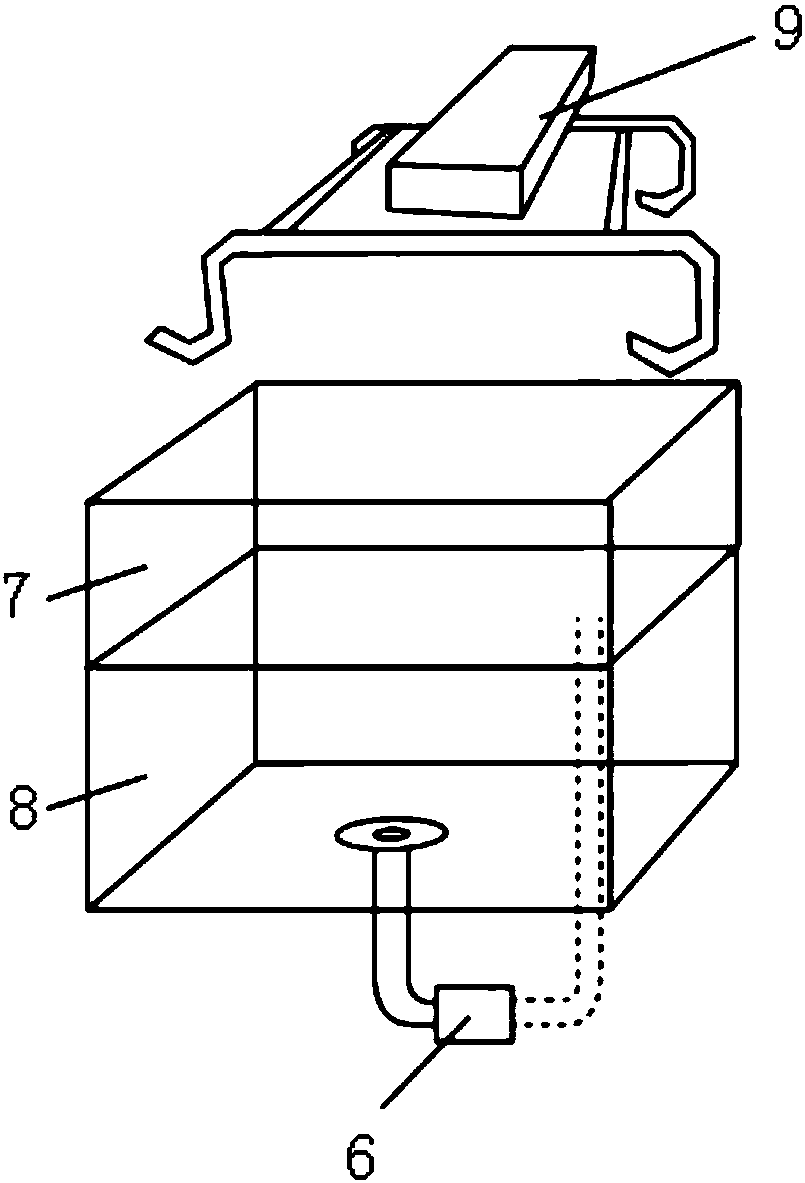

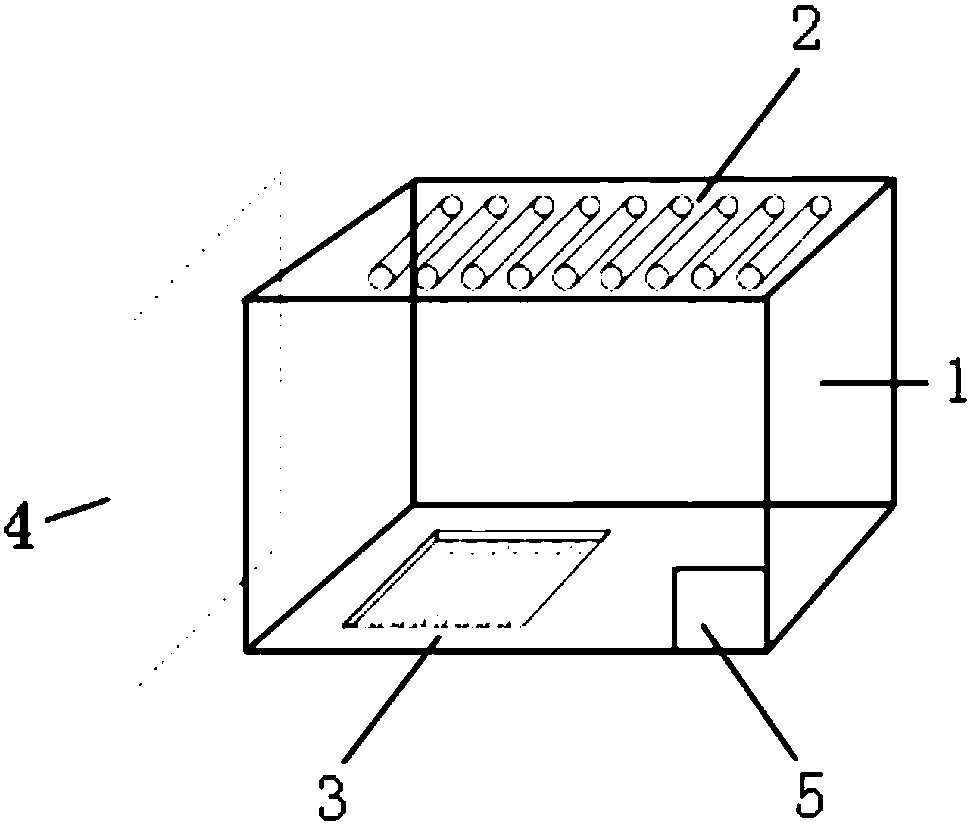

Image

Examples

Embodiment 1

[0036] Methyl styrene: 180g;

[0037] Polypropylene glycol diacrylate: 220g;

[0038] Trimethylolpropane trimethacrylate: 300g;

[0039] Polypentyl glycol dimethacrylate: 300g;

[0040] 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole: 0.01g;

[0041] 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole: 0.02g;

[0042] 2-hydroxy-4-methoxybenzophenone: 0.02g;

[0043] 2,2'-Dimethyl-4-methylaminobenzophenone 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzene

[0044] Triazole: 0.03g;

[0045] Pigment: Pigment blue: 0.5g; Pigment green: 0.2g.

[0046] Photocuring initiator: 1.2 g of acylphosphine oxide.

[0047] The mixture obtained according to the above formula was sheared for 2 hours at a stirring speed of 2000 rpm, and then vacuumed at a degree of vacuum of 1.0*10 -2 Vacuum degassing under Pascal vacuum. Then filter with a filter element of 1 μm, pour into the glass mold prepared in advance after filtering, and put the glass mold into an ult...

Embodiment 2

[0051] Methyl styrene: 180g;

[0052] Polypropylene glycol diacrylate: 220g;

[0053] Trimethylolpropane trimethacrylate: 300g;

[0054] Polypentyl glycol dimethacrylate: 300g;

[0055] 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole: 0.03g;

[0056] 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole: 0.03g;

[0057] 2-hydroxy-4-methoxybenzophenone: 0.05g;

[0058] 2,2'-Dimethyl-4-methylaminobenzophenone 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzene

[0059] Triazole: 0.06g;

[0060] Pigment: Pigment blue: 0.5g; Pigment green: 0.2g.

[0061] Photocuring initiator: 1.5 g of acylphosphine oxide.

[0062] The mixture obtained according to the above formula was sheared for 2 hours at a stirring speed of 2500 rpm, and then vacuumed at a degree of vacuum of 1.0*10 -2 Vacuum degassing under Pascal vacuum. Then filter with a filter element of 0.5 μm, pour it into a prepared glass mold after filtering, put the glass mold into an ultraviolet curin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com