PA-PP alloy and preparation method thereof

A PA-PP and alloy technology, applied in the field of high-performance and low-cost PA-PP alloy materials and their preparation, can solve the problems of performance degradation and high energy consumption, and achieve bright practical prospects and obvious social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

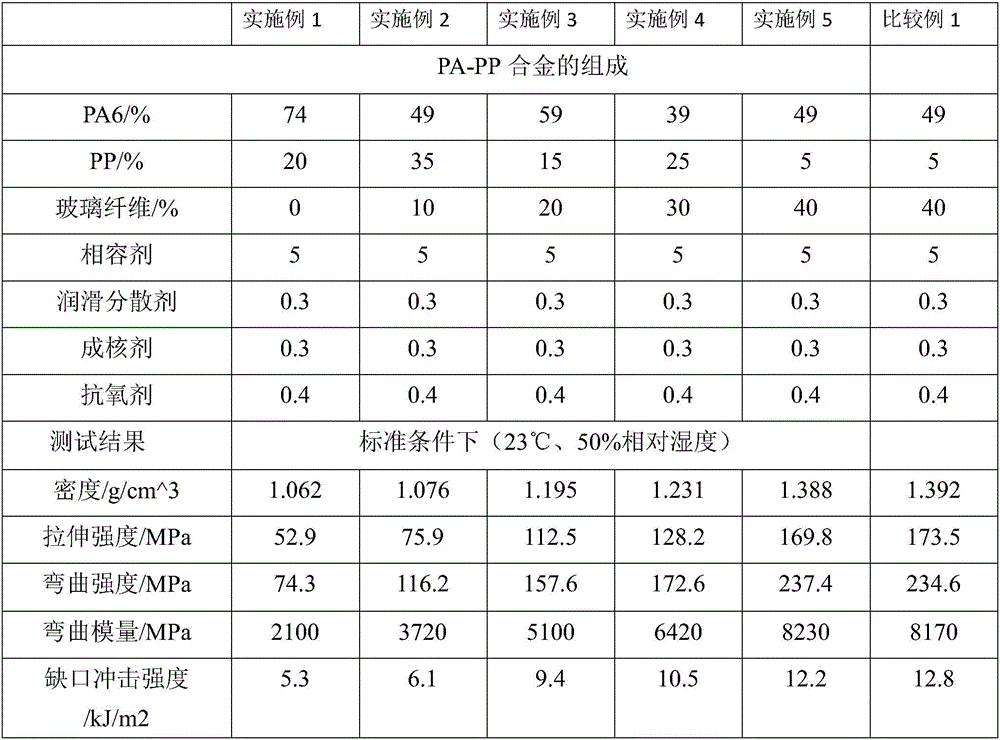

Embodiment 1

[0033] A high-performance and low-cost PA-PP alloy, its composition by mass percentage is: recycled PA6 resin 74%, PP resin 25%, polypropylene grafted maleic anhydride 5%, silicone masterbatch 0.3%, superfine Talc powder 0.3%, antioxidant 10100.4%. Wherein, the regenerated PA6 resin is regenerated PA6 resin obtained by crushing, cleaning, separating and drying recycled waste nylon carpets and extruding and granulating. Its relative viscosity is 2.0-2.7 according to the Ubbelohde viscosity method, wherein PA6 is Polycaprolactam. The PP resin is polypropylene.

[0034] Preparation method: (1) Dry regenerated PA6 at 100°C-120°C for more than 8 hours, dry PP at 90°C-110°C for more than 2 hours, polypropylene grafted with maleic anhydride, silicone masterbatch, superfine Talc powder and antioxidant 1010 were dried at 70°C to 100°C for 4 hours; (2) After drying, regenerated PA6, PP, polypropylene grafted maleic anhydride, silicone masterbatch, ultrafine talc powder, anti-oxidant ...

Embodiment 2

[0036] A high-performance and low-cost PA-PP alloy, the composition of which is: 49% of recycled PA6 resin, 35% of PP resin, 10% of alkali-free chopped glass fiber whose surface has been treated with silane coupling agent, and poly Propylene-grafted maleic anhydride 5%, silicone masterbatch 0.3%, ethylene-methacrylic acid copolymer zinc salt 0.3%, antioxidant 1010 and antioxidant 168 compound 0.4%. Wherein, the regenerated PA6 resin is regenerated PA6 resin obtained by crushing, cleaning, separating and drying recycled waste nylon carpets and extruding and granulating. Its relative viscosity is 2.0-2.7 according to the Ubbelohde viscosity method, wherein PA6 is polycaprolactam. The PP resin is polypropylene.

[0037] Preparation method: (1) Dry regenerated PA6 at 100°C to 120°C for more than 8 hours, dry PP at 90°C to 110°C for more than 2 hours, and use alkali-free chopped glass fibers whose surface has been treated with silane coupling agent , polypropylene grafted maleic ...

Embodiment 3

[0039] A high-performance and low-cost PA-PP alloy, the composition of which is: 59% of recycled PA6 resin, 15% of PP resin, 20% of alkali-free chopped glass fiber whose surface has been treated with silane coupling agent, and poly Propylene grafted maleic anhydride 5%, silicone masterbatch 0.3%, nano-SiO 2 0.3%, antioxidant 2450 and antioxidant 168 compound 0.4%. Wherein, the regenerated PA6 resin is regenerated PA6 resin obtained by crushing, cleaning, separating and drying recycled waste nylon carpets and extruding and granulating. Its relative viscosity is 2.0-2.7 according to the Ubbelohde viscosity method, wherein PA6 is Polycaprolactam. The PP resin is polypropylene.

[0040] Preparation method: (1) Dry regenerated PA6 at 100°C to 120°C for more than 8 hours, dry PP at 90°C to 110°C for more than 2 hours, and use alkali-free chopped glass fibers whose surface has been treated with silane coupling agent , polypropylene grafted maleic anhydride, silicone masterbatch, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com