Waterborne two-component automotive interior paint and preparation method thereof

A water-based two-component, automotive interior technology, applied in the field of coatings, can solve the problems of odor residue, strong odor, user influence, etc., to save time, reduce air pollution, and low VOC emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

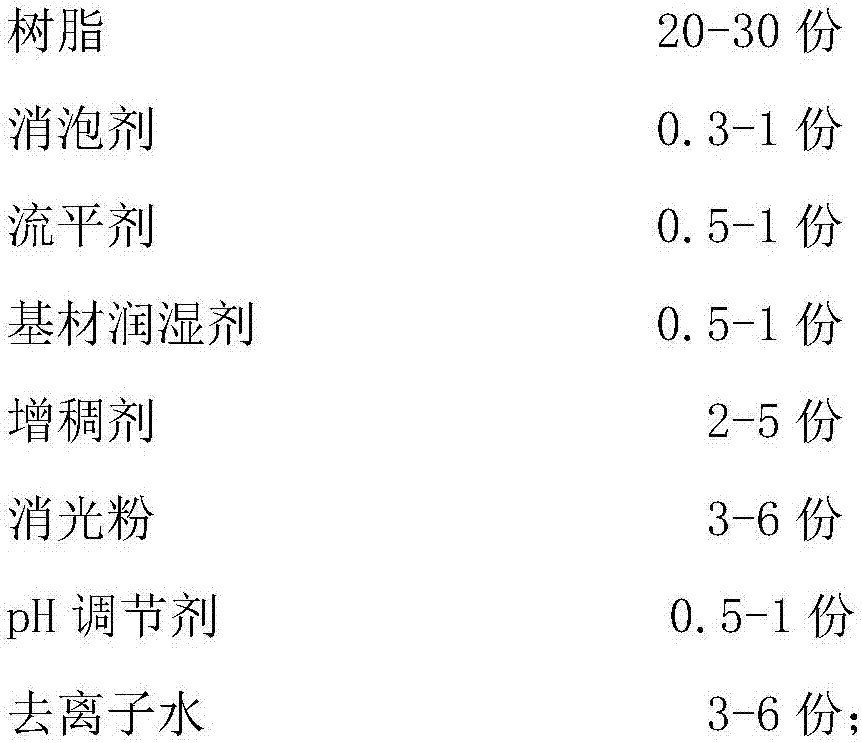

[0048] The preparation method of water-based two-component automotive interior paint, comprises the steps:

[0049] Step 1, take each component by weight, set aside;

[0050] Step 2. Mix and stir the resin, dispersant, half of the co-solvent, deionized water and titanium dioxide evenly, add zirconium beads, and grind for 1.5-2 hours;

[0051] Step 3. While stirring the white slurry obtained in step 2, add leveling agent, substrate wetting agent, defoamer, half of the co-solvent, and part of deionized water, and stir evenly;

[0052] Step 4, add matting powder to the mixed solution obtained in step 3 while stirring, and increase the stirring speed, and stir evenly;

[0053] Step 5, add the thickener while stirring, and adjust the pH value between 7.5-8.5 with a pH regulator.

Embodiment 1

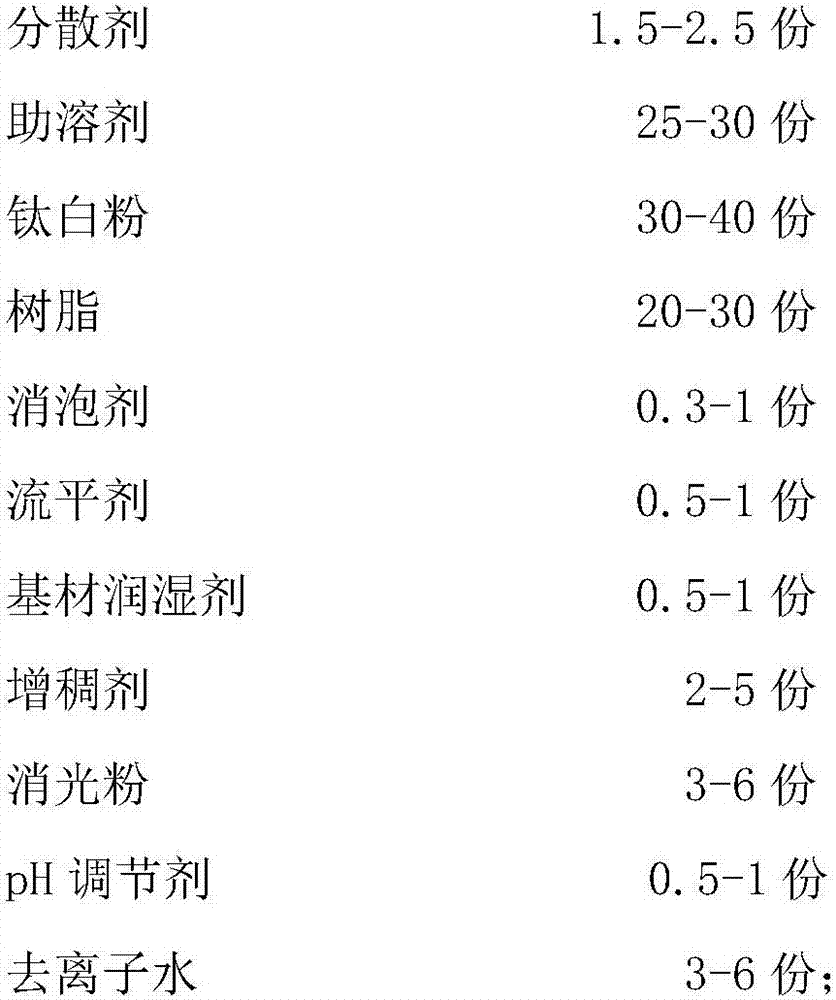

[0056] Step 1. Weigh each component according to the following parts by weight and set aside: 1.5 parts of dispersant; 25 parts of cosolvent; 30 parts of titanium dioxide; 20 parts of resin; 0.3 parts of defoamer; 0.5 parts of leveling agent; 0.5 parts of agent; 2 parts of thickener; 3 parts of matting powder; 0.5 parts of pH regulator; 3 parts of deionized water;

[0057] Step 2. Mix and stir the resin, dispersant, 12.5 parts of co-solvent, deionized water and titanium dioxide evenly, add zirconium beads, grind for 1.5 hours until the fineness is less than 10 microns, and produce slurry;

[0058] Step 3. While stirring the white paste obtained in step 2, add leveling agent, substrate wetting agent, defoamer, 12.5 parts of co-solvent, and deionized water at a low speed of 500-800 rpm Stir evenly under shear force;

[0059] Step 4. Add matting powder to the mixture obtained in step 3 while stirring, and increase the stirring speed, disperse until the fineness is less than 20 m...

Embodiment 2

[0062] Step 1. Weigh each component according to the following parts by weight and set aside: 2.5 parts of dispersant; 30 parts of cosolvent; 40 parts of titanium dioxide; 30 parts of resin; 1 part of defoamer; 1 part of leveling agent; substrate wetting 1 part of agent; 5 parts of thickener; 6 parts of matting powder; 1 part of pH regulator; 6 parts of deionized water;

[0063] Step 2. Mix and stir the resin, dispersant, half of the co-solvent, deionized water and titanium dioxide evenly, add zirconium beads, grind for 2 hours until the fineness is less than 10 microns, and produce slurry;

[0064] Step 3. While stirring the white paste obtained in step 2, add leveling agent, base material wetting agent, defoamer, half of the co-solvent, and part of deionized water, at a low speed of 500-800 rpm Stir evenly under shear force;

[0065] Step 4. Add matting powder to the mixture obtained in step 3 while stirring, and increase the stirring speed, disperse until the fineness is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com